Tungsten carbide bushings are widely used in industries that require high durability and resistance to wear, such as automotive, aerospace, and manufacturing.

To ensure that these bushings perform optimally, it is crucial to adhere to specific machining tolerances during their manufacturing process.

In this blog, we will explore the common machining tolerances for tungsten carbide bushings, how these tolerances affect performance, and the importance of precision in achieving long-lasting results.

What are Machining Tolerances?

Machining tolerances refer to the allowable deviation from the specified dimensions of a component.

In simpler terms, they define how precisely a part must be manufactured to meet its design specifications.

Tolerances are essential because even small deviations can lead to performance issues, increased wear, or failure, especially in high-performance components like tungsten carbide bushings.

Tolerance: The difference between the maximum and minimum allowable size.

Precision: The degree to which a part’s dimensions conform to the intended design.

For tungsten carbide bushings, precise machining tolerances ensure a proper fit with the mating components, such as shafts and housings, which directly affects their performance and lifespan.

Common Machining Tolerances for Tungsten Carbide Bushings

Tungsten carbide bushings are typically manufactured with very tight tolerances due to their high performance and wear-resistance requirements.

The machining process can vary, but the following are some of the most common tolerances applied to tungsten carbide bushings:

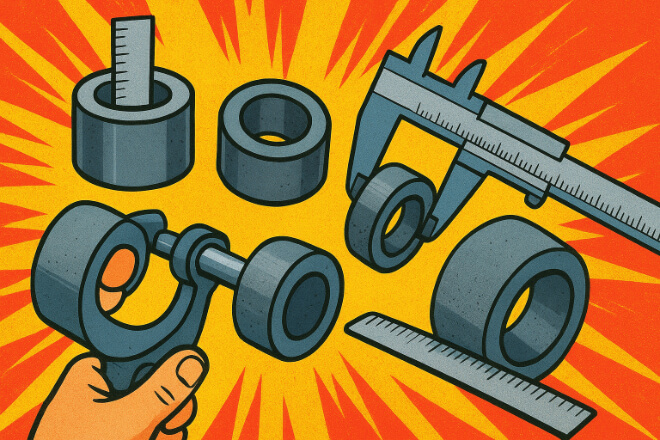

1). Diametrical Tolerance

Diametrical tolerance refers to the allowable deviation in the diameter of the bushing.

Since bushings typically fit around a shaft, ensuring that the diameter is within the correct tolerance range is critical for achieving the right clearance and preventing issues like excessive wear or friction.

Common Range: ±0.005 to ±0.020 mm

Importance: Ensures proper fit and alignment with the shaft, reducing friction and wear.

2). Length Tolerance

Length tolerance defines the allowable deviation in the length of the bushing.

This tolerance is important for applications where the bushing must fit into a specific space or housing, and any deviation can lead to misalignment or failure.

Common Range: ±0.010 to ±0.050 mm

Importance: Ensures proper assembly and prevents issues with alignment in the machine.

3). Roundness Tolerance

Roundness tolerance ensures that the cylindrical shape of the bushing is uniform.

A bushing that is not perfectly round can cause uneven wear, increase friction, and ultimately reduce the lifespan of both the bushing and the shaft.

Common Range: ≤ 0.003 mm

Importance: Prevents uneven wear and minimizes the chances of premature failure due to friction.

4). Surface Finish Tolerance (Ra Value)

The surface finish of the tungsten carbide bushing is crucial for reducing friction and improving wear resistance.

The Ra value, or arithmetic average roughness, is used to measure the smoothness of the surface. A lower Ra value indicates a smoother surface, which reduces friction and enhances performance.

Common Range: Ra ≤ 0.2 µm (for high-performance applications)

Importance: Improves efficiency, reduces wear, and extends the lifespan of both the bushing and the mating components.

How Tolerances Affect the Performance of Tungsten Carbide Bushings

The machining tolerances of tungsten carbide bushings directly influence their performance in various ways:

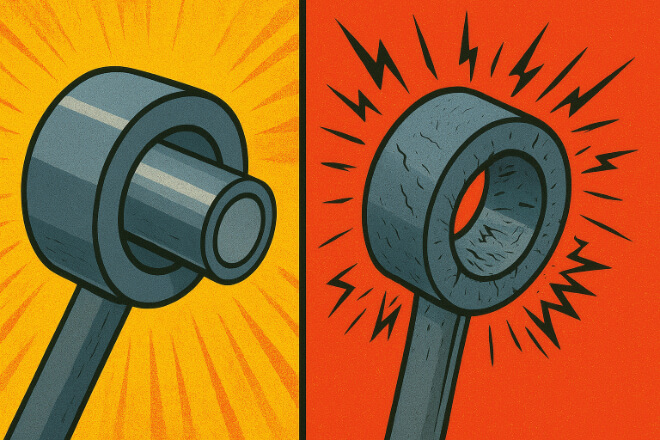

1). Wear Resistance

Tighter tolerances ensure that the bushing fits precisely with the shaft or housing, reducing friction and preventing uneven wear.

A poor fit caused by loose tolerances can lead to increased wear and tear, leading to premature failure of the bushing.

2). Load Distribution

Properly machined bushings ensure that the load is evenly distributed across the surface.

This is particularly important in high-load applications, as uneven load distribution can lead to stress points, cracks, and eventual failure.

3). Friction Reduction

Achieving the correct surface finish and dimensional tolerances helps reduce friction between the bushing and other moving parts.

Less friction means less heat generation, which in turn reduces the likelihood of material degradation and extends the lifespan of the components.

Balancing Tolerances with Cost and Production Time

While tighter tolerances provide better performance, they also increase the complexity of the manufacturing process.

This can lead to higher production costs and longer manufacturing times. Therefore, manufacturers must balance the required tolerances with cost considerations.

1). Tighter tolerances typically result in:

Higher precision

Longer machining time

Higher material costs

Better overall performance

2). Looser tolerances may:

Reduce costs and machining time

Lead to a higher risk of wear and failure

Affect the reliability and longevity of the bushing

Common Machining Tolerances for Tungsten Carbide Bushings

| Tolerance Type | Common Range | Importance |

|---|---|---|

| Diametrical Tolerance | ±0.005 to ±0.020 mm | Ensures proper fit and alignment with the shaft |

| Length Tolerance | ±0.010 to ±0.050 mm | Ensures correct fit in housing or assembly |

| Roundness Tolerance | ≤ 0.003 mm | Prevents uneven wear and minimizes premature failure |

| Surface Finish (Ra Value) | Ra ≤ 0.2 µm | Reduces friction, improves efficiency and wear resistance |

How to Achieve Precision in Tungsten Carbide Bushing Machining

To achieve the ideal machining tolerances for tungsten carbide bushings, manufacturers need to follow best practices and utilize advanced machining techniques:

1). Advanced Grinding Techniques

Tungsten carbide bushings are often machined using grinding techniques to achieve precise dimensions and surface finishes.

Using high-quality diamond grinding wheels can help achieve tighter tolerances, especially in high-performance applications.

2). Precision Lapping

Lapping is a finishing process that helps achieve ultra-smooth surface finishes.

It is often used in applications where low friction and high wear resistance are critical, such as in high-speed machinery.

3). Use of CNC Machines

Modern CNC (Computer Numerical Control) machines enable precise control over machining operations, helping to achieve tight tolerances and reducing human error.

These machines can produce high-precision components in a consistent and repeatable manner.

Conclusion

Machining tolerances are crucial in ensuring the optimal performance and longevity of tungsten carbide bushings.

Achieving the correct tolerances in dimensions, surface finish, and roundness ensures proper fit, minimizes wear, and enhances the reliability of machinery.

By balancing precision with production costs, manufacturers can optimize the performance of tungsten carbide bushings in various industrial applications.

If you want to know more details about any company, please feel free to contact us.