In many industries, the performance of machines depends on the quality of their wear components. These are the parts exposed to high friction, pressure, or cutting forces.

The most common materials used are carbide (tungsten carbide) and HSS (high-speed steel).

Both have their place in modern production, but the choice between carbide and HSS can make a huge difference in cost, efficiency, and productivity.

This article compares carbide and HSS wear components to help decision-makers choose the right option for their business needs.

What Are Carbide Wear Components?

Carbide wear components are made from tungsten carbide particles bonded with a metal binder such as cobalt.

They are extremely hard, second only to diamond, and designed to resist wear, abrasion, and heat.

Common examples include carbide inserts, bushings, seal rings, nozzles, and cutting tools.

Their main strength lies in their long service life and ability to stay sharp under heavy use.

Key benefits of carbide wear components:

Extreme hardness and wear resistance.

Long tool life, reducing replacements.

High heat resistance, even in cutting and drilling.

Suitable for very tough and abrasive environments.

What Are HSS Wear Components?

HSS, or high-speed steel, is an alloy that contains iron, carbon, and elements such as tungsten, molybdenum, and chromium.

HSS was developed to cut faster than traditional carbon steels and is widely used for cutting tools and wear parts.

HSS wear components include drill bits, end mills, saw blades, and punches. They are less hard than carbide but offer good toughness and are less likely to chip or break under sudden force.

Key benefits of HSS wear components:

Lower cost compared to carbide.

Good toughness and shock resistance.

Easy to grind and re-sharpen.

Performs well in general-purpose applications.

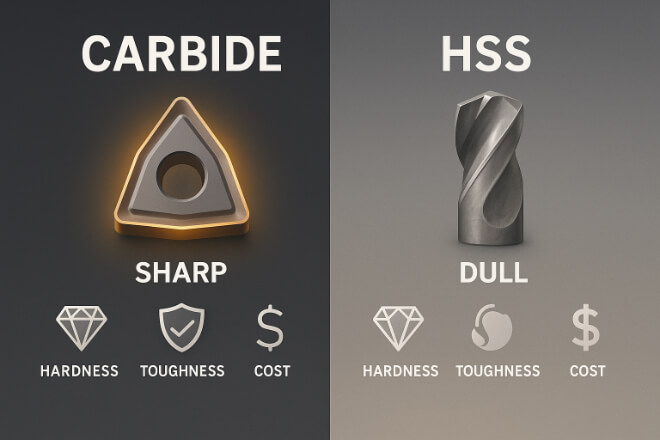

Key Differences Between Carbide and HSS

While both materials serve important roles, their differences are clear:

1). Hardness

Carbide: Extremely hard, resists abrasion.

HSS: Softer than carbide, wears faster.

2). Toughness

Carbide: Hard but less tough, may chip under shock.

HSS: Tougher, better for impact conditions.

3). Heat Resistance

Carbide: Maintains strength at high temperatures.

HSS: Loses hardness when overheated.

4). Cost

Carbide: Higher upfront cost, longer life.

HSS: Lower price, but needs frequent replacement.

5). Applications

Carbide: Best for high-volume, high-speed, and abrasive operations.

HSS: Better for general, low-volume, or impact-heavy work.

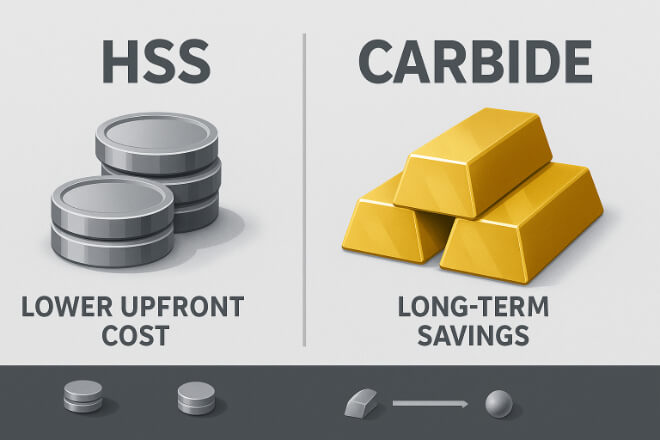

Cost Comparison: Short-Term vs Long-Term

Many decision-makers look at price first, but total cost of ownership is more important.

HSS parts are cheaper to buy but wear out quickly. This leads to more replacements and higher downtime costs.

Carbide parts cost more initially but last much longer, saving money over the full lifecycle.

When considering machine downtime, labor costs for replacements, and lost production time, carbide almost always provides better value over time.

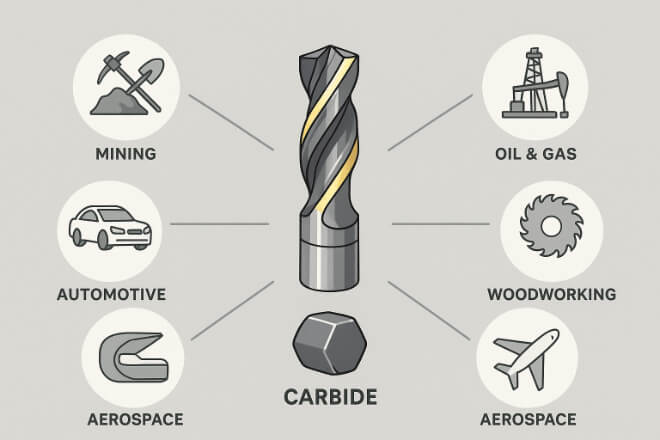

Performance in Different Industries

The choice between carbide and HSS depends on the industry and application.

Mining and Construction: Carbide is preferred due to extreme wear and abrasive conditions. HSS cannot handle such environments for long.

Metalworking: Carbide tools cut faster and stay sharp, but HSS may still be used for small jobs or lower budgets.

Woodworking and Paper Cutting: Carbide blades provide long-lasting sharpness and reduce waste, while HSS is used for less demanding tasks.

Oil and Gas: Carbide wear parts, like seal rings and valve components, resist pressure and corrosion better than HSS.

Automotive and Aerospace: Carbide ensures precision and longer tool life, important for safety and accuracy.

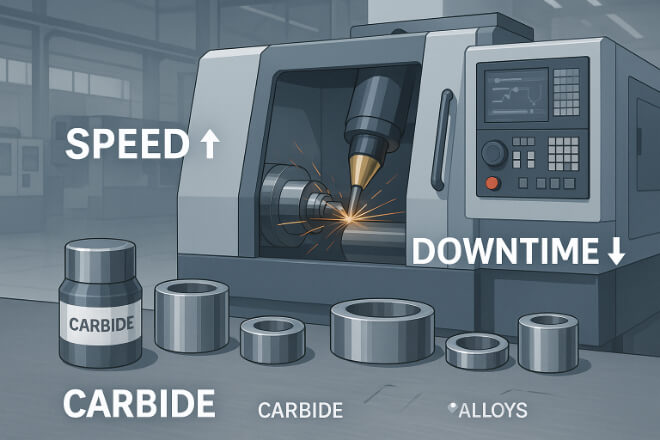

Productivity and Efficiency Benefits

Carbide components allow machines to run at higher speeds and for longer periods without interruption. This results in:

Higher output per hour.

Less downtime for tool changes.

Better surface finish and accuracy.

HSS tools, while cheaper, often require slower speeds and frequent re-sharpening. This reduces efficiency and increases production costs over time.

Environmental and Sustainability Aspects

Using carbide components also reduces waste. Since they last longer, fewer parts need to be produced and replaced. Tungsten carbide can also be recycled, lowering environmental impact.

HSS parts, although recyclable, wear out much faster, creating more waste and requiring more frequent energy use in production and replacement.

Choosing the Right Option for Your Business

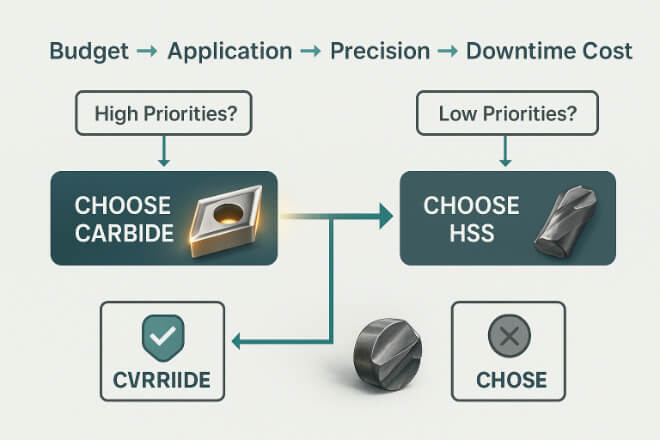

The decision between carbide and HSS should be based on:

Budget: Short-term savings (HSS) vs long-term value (carbide).

Application: Light-duty tasks (HSS) vs heavy-duty, high-volume work (carbide).

Precision Needs: General work (HSS) vs accuracy and reliability (carbide).

Downtime Tolerance: If downtime is costly, carbide is the clear winner.

For most modern industries where productivity and quality are top priorities, carbide wear components deliver the best results.

Conclusion

Both carbide and HSS wear components have their strengths, but when it comes to long-term cost savings, productivity, and durability, carbide clearly outperforms HSS.

Decision-makers should carefully evaluate not just the purchase cost but also the total lifecycle cost and performance impact.

For companies that want to reduce downtime, improve efficiency, and stay competitive, tungsten carbide wear parts are the smarter choice.

If you want to know more details about any company, please feel free to contact us.