In today’s competitive industries, companies face growing pressure to lower costs while keeping machines running smoothly.

Equipment downtime, frequent part replacements, and inefficient tools can quickly increase expenses. This is why many decision-makers are turning to tungsten carbide wear parts.

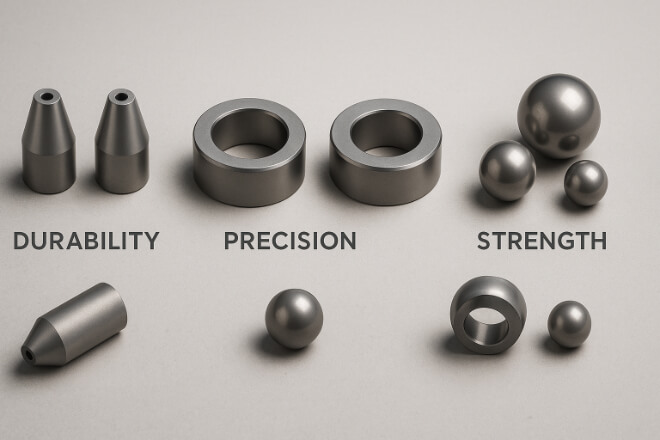

Tungsten carbide, known for its extreme hardness and durability, is used to produce a wide range of industrial components.

While carbide parts may cost more at the beginning, their long service life and reliability deliver significant cost benefits in the long run.

This article explains the cost advantages of tungsten carbide wear parts, compares them with other materials, and shows why they are a smart investment for companies across multiple industries.

What Are Tungsten Carbide Wear Parts?

Tungsten carbide wear parts are components made from a mixture of tungsten carbide (WC) powder and a binder metal such as cobalt or nickel. This combination results in a material that is both very hard and tough.

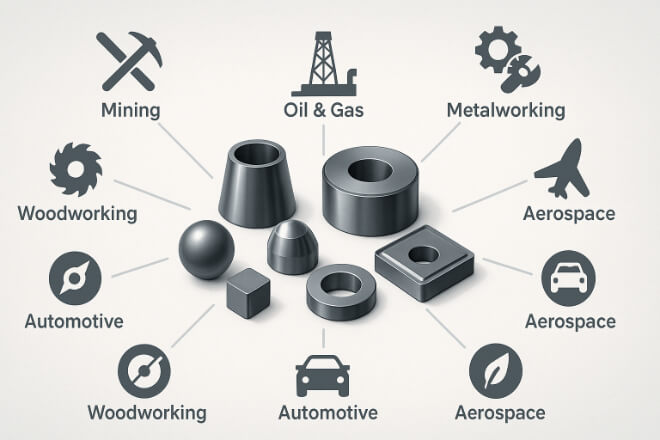

These parts are used in industries like mining, oil and gas, metalworking, woodworking, and manufacturing. Examples include carbide bushings, seal rings, nozzles, inserts, and balls.

Their main role is to resist wear and extend the lifetime of machinery under high stress, friction, or impact conditions.

Initial Cost vs. Long-Term Savings

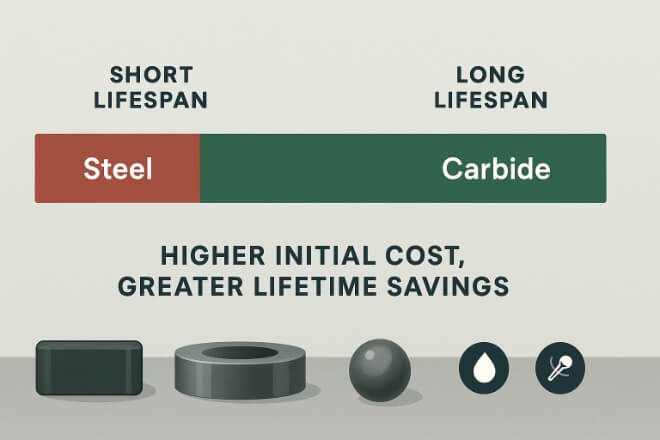

At first glance, tungsten carbide parts are more expensive than steel or alloy components. However, focusing only on purchase price can be misleading.

Steel parts wear out quickly and require frequent replacement.

Alloy parts last longer but still need regular maintenance.

Carbide parts last much longer, often several times the lifespan of steel.

When companies calculate the total cost of ownership, they often find that carbide saves money because fewer replacements are needed and machines experience less downtime.

Over time, the higher initial price of carbide parts is outweighed by their durability and reliability.

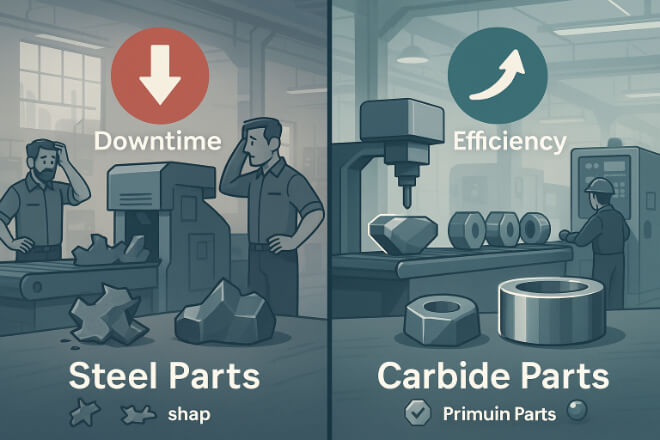

Lower Downtime and Maintenance Costs

Machine downtime is one of the biggest hidden costs in industry. Every time a machine stops for repairs or part replacement, production slows or halts. This leads to missed deadlines, higher labor costs, and lost profits.

Carbide wear parts reduce downtime because they stay in service much longer than traditional materials.

They also maintain their shape and performance, which means less time spent on adjustments or repairs. Lower maintenance frequency results in better efficiency and cost savings.

Improved Productivity and Efficiency

Productivity depends on how well tools and parts perform. When components wear out too quickly, machines cannot run at full speed or produce consistent quality. Tungsten carbide parts solve this problem:

They maintain sharpness and strength over long periods.

They allow machines to run at higher speeds.

They deliver better precision and accuracy.

For industries such as metal cutting, woodworking, or mining, higher productivity means more output in less time. This directly improves profitability.

Reduced Waste and Longer Service Life

Replacing worn-out parts creates waste, both in materials and energy. Tungsten carbide parts last longer, which reduces the number of replacements needed.

This provides two key cost benefits:

Material Savings: Fewer parts purchased over time.

Labor Savings: Less time spent replacing or adjusting components.

In addition, carbide parts keep their size and shape for longer, reducing errors and defective products.

This helps companies maintain high-quality standards while reducing scrap and rework costs.

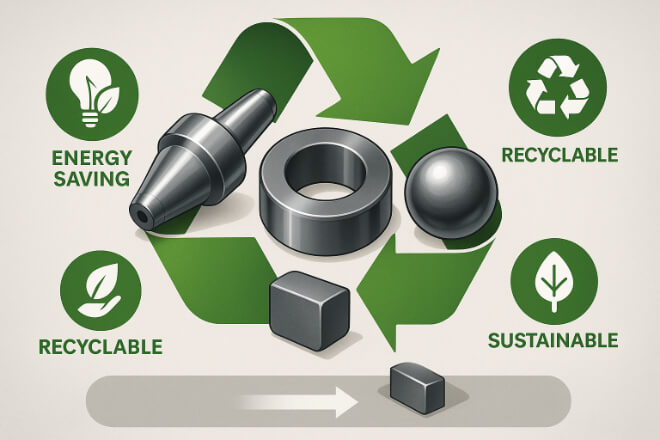

Energy Efficiency and Sustainability Benefits

Cost savings are not only about money spent on parts. Energy efficiency also plays a big role. Machines with worn-out components require more energy to function.

In contrast, carbide parts reduce friction, maintain sharp edges, and keep machines running smoothly.

This translates into lower power consumption and reduced operating costs. Additionally, tungsten carbide can be recycled, which lowers material costs and supports sustainability goals.

For companies aiming to reduce carbon footprint, this adds an extra layer of cost benefit.

Industry Examples of Cost Benefits

Different industries see measurable cost advantages when using tungsten carbide wear parts:

Mining and Construction: Longer-lasting drill bits and crusher components mean fewer replacements and less downtime.

Oil and Gas: Seal rings and valve components maintain integrity under high pressure, reducing costly failures.

Metalworking: Cutting tools and inserts stay sharp longer, leading to faster production and fewer tool changes.

Woodworking and Paper: Carbide knives and blades reduce waste and improve cutting efficiency.

Aerospace and Automotive: Precision parts ensure consistent quality, reducing rework and scrap costs.

Across industries, the long-term savings are clear: carbide parts lower overall expenses while improving performance.

Return on Investment (ROI) with Carbide

For decision-makers, the most important measure is return on investment. Tungsten carbide wear parts deliver strong ROI by:

Cutting replacement costs.

Reducing downtime.

Increasing machine productivity.

Lowering energy use.

Improving quality and reducing waste.

When calculating ROI, many companies find that carbide parts pay for themselves within months due to these combined benefits. Over the lifetime of equipment, the savings become even greater.

How to Maximize Cost Benefits

To get the most from tungsten carbide wear parts, companies should:

Work with Reliable Suppliers – Quality matters. Poorly made carbide parts may not deliver the same benefits.

Select the Right Grade – Different carbide grades suit different conditions. Choosing the correct one ensures maximum life and efficiency.

Use Proper Coatings – Adding protective coatings like TiN or DLC can further increase wear resistance.

Schedule Preventive Maintenance – Even carbide lasts longer when machines are well-maintained.

By following these steps, companies can achieve the maximum cost advantage from their carbide investment.

Conclusion

Tungsten carbide wear parts are more than just strong materials. They are cost-saving solutions that reduce downtime, extend service life, improve productivity.

And lower total operating costs. While the purchase price is higher, the long-term benefits far outweigh the initial expense.

For decision-makers looking to cut costs, increase efficiency, and maintain competitiveness, tungsten carbide wear parts are the smart choice.

If you want to know more details about any company, please feel free to contact us.