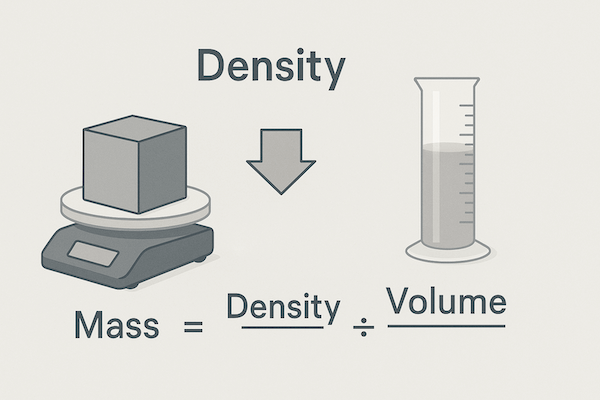

What is Density?

Density is a fundamental physical property that refers to the mass of a substance per unit volume. It is typically expressed in grams per cubic centimeter (g/cm³) or kilograms per cubic meter (kg/m³). The formula is simple:

Density = Mass ÷ Volume

This property plays a critical role in material selection, as it influences strength, wear resistance, thermal conductivity, and overall performance in demanding environments.

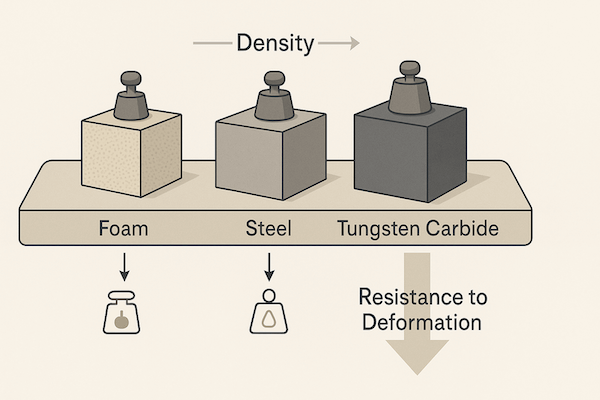

Why Does Density Matter in Engineering Materials?

In industrial applications, density is more than just a number—it affects how a material behaves under pressure, heat, and mechanical stress. High-density materials typically offer:

Improved wear resistance

Higher inertia and stability

Enhanced impact energy absorption

This makes dense materials ideal for applications that require durability and precision.

The Density of Tungsten Carbide

Tungsten carbide (WC), when bonded with a metallic binder such as cobalt (Co) or nickel (Ni), forms cemented carbide, which is known for its exceptional hardness and wear resistance.

Depending on the binder content and specific composition, the density of cemented carbide typically ranges between 13.8 – 15.0 g/cm³.

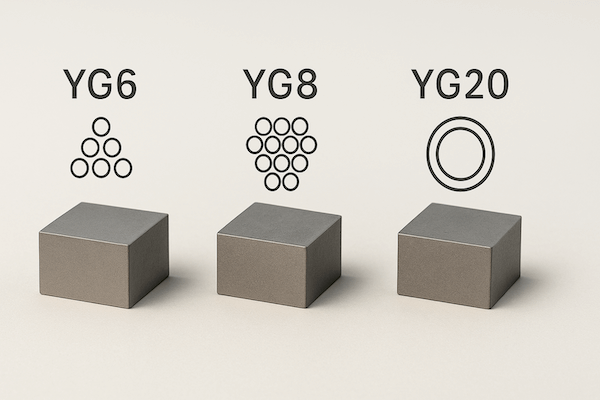

| Grade | Typical Density (g/cm³) | Binder Content |

|---|---|---|

| YG6 | 14.9 | 6% Cobalt |

| YG8 | 14.7 | 8% Cobalt |

| YG20 | 13.8 | 20% Cobalt |

Higher cobalt content lowers the overall density but improves toughness, while lower binder content results in higher density and improved hardness.

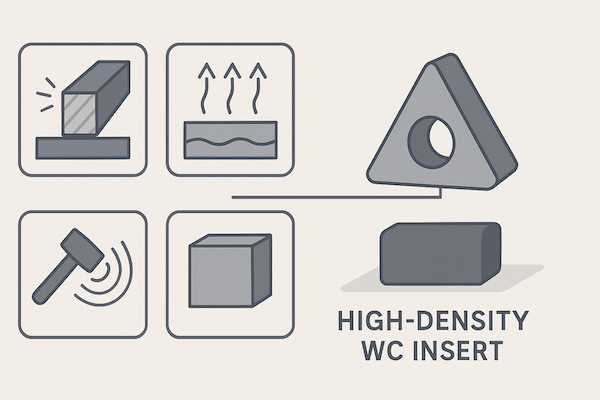

Density’s Role in Tungsten Carbide Tool Performance

In carbide tools, density is closely related to both mechanical properties and application performance:

1. Wear Resistance

Higher density often correlates with more WC content, which improves abrasion resistance, crucial in cutting tools, mining bits, and nozzles.

2. Thermal Conductivity

Dense carbide has better thermal conductivity, helping dissipate heat during high-speed machining.

3. Impact Strength

Optimizing density by adjusting binder ratio helps balance hardness and toughness—for example, in hammer drills or impact tools.

4. Dimensional Stability

A denser microstructure ensures less porosity and more consistent performance under mechanical or thermal stress.

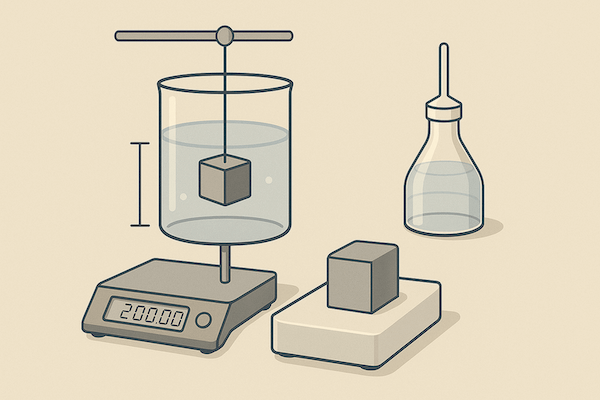

Measuring Density in Carbide Manufacturing

Accurate density measurement is part of quality control in carbide production. Common methods include:

Archimedes’ Principle (Water Displacement Method)

Helium Pycnometry (for high-precision)

Geometrical calculation (mass/volume for regular shapes)

Maintaining tight density tolerances ensures each batch of carbide meets application requirements.

Conclusion

Density is a core property that significantly influences the performance of tungsten carbide tools. Whether in cutting, drilling, sealing, or wear applications, the right density ensures optimal strength, wear resistance, and longevity. Understanding how density interacts with binder content and microstructure is key to producing high-performance cemented carbide solutions across industries.