Dimensional Tolerance & Surface Finish: The Ultimate Guide

Learn how precision impacts performance in sealing rings, nozzles, dies, and more.

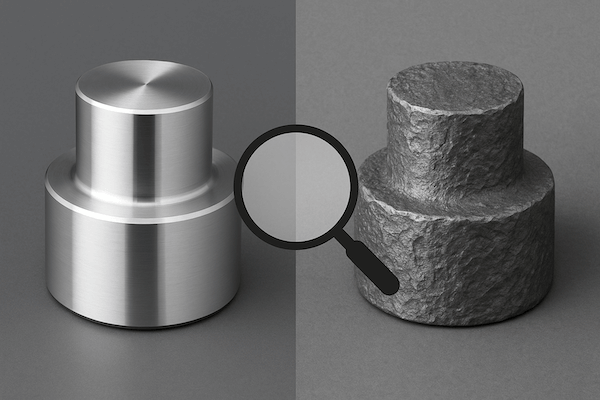

Precision Basics: Tolerance, Finish, and Why They Matter

Understand the key concepts that affect how your parts fit and function: dimensional tolerance, surface finish, and the role of precision in real-world applications.

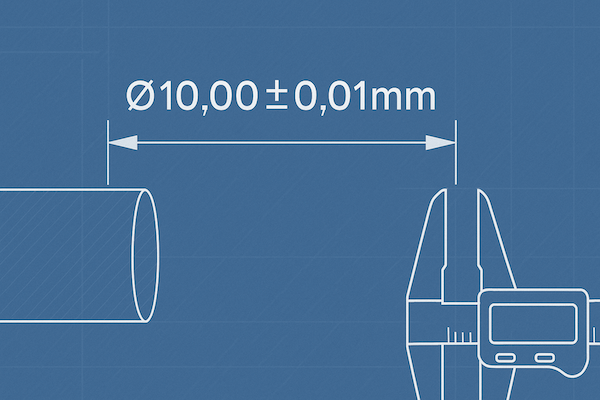

What Is Dimensional Tolerance?

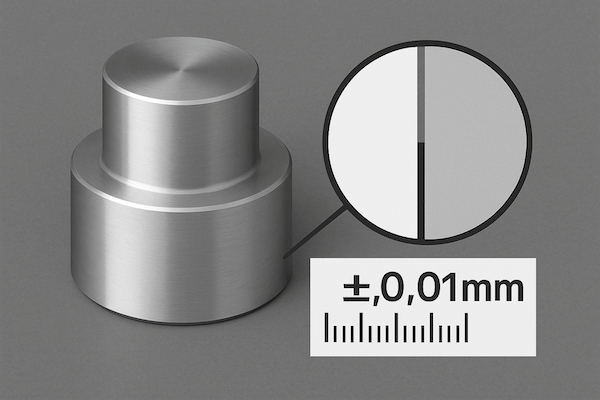

Dimensional tolerance tells us how much size can vary from the drawing. It’s like saying: ‘This part should be 10mm, but a little more or less is okay—maybe ±0.01mm.

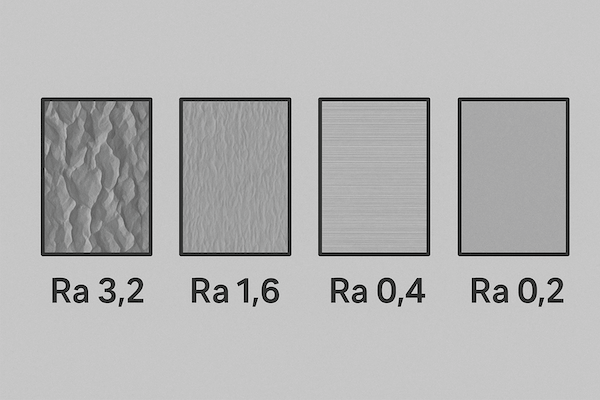

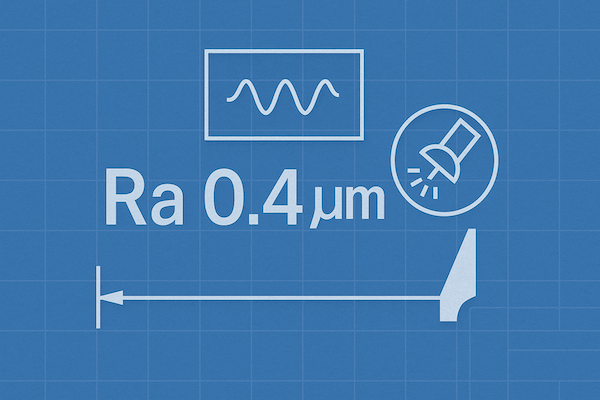

What Is Surface Finish?

Surface finish tells us how smooth or rough a surface is. It’s measured in Ra (roughness average). Lower Ra = smoother surface. High Ra = rougher surface.

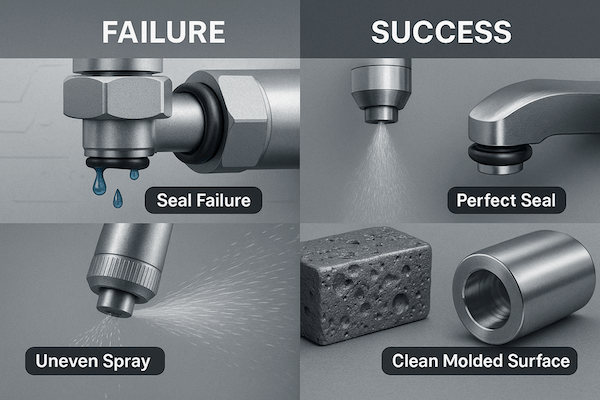

Why Precision Matters in Real Use

Precision isn’t just about numbers—it decides if a seal leaks, if a nozzle sprays straight, or if a mold makes perfect parts. Poor tolerance or surface finish can cause early failure or bad performance.

Why It Matters for Your Application

Every part has its own precision needs. This chart helps you understand what accuracy is needed and why it matters.

| Application | Dimensional Tolerance | Surface Finish (Ra µm) | Why It Matters |

|---|---|---|---|

| Sealing Rings | ±0.002 mm | ≤ 0.2 | Must be very tight to avoid leaks |

| Carbide Nozzles | ±0.01 mm | 0.4 – 0.8 | Accurate flow control |

| Molds & Dies | ±0.003 mm | ≤ 0.4 | Ensures product shape precision |

| General Wear Parts | ±0.05 mm | 1.2 – 3.2 | Less critical fit |

| Valve Seats | ±0.005 mm | ≤ 0.2 | High sealing performance |

How to Specify Tolerance and Surface Finish on Your Drawing

Clearly mark dimensions with tolerances, like ‘Ø10.00 ±0.01mm’. Add surface finish symbols, such as Ra 0.4µm. If unsure, ask your supplier for advice.

Mark the Tolerance Clearly

Always write the allowed size range clearly. For example: Ø10.00 ±0.01mm. This tells the factory how exact the part must be.

Add Surface Finish Symbol

Not sure what to write? Ask your supplier. A good supplier will help choose the right tolerance and surface finish for your part.

When in Doubt, Ask

Precision isn’t just about numbers—it decides if a seal leaks, if a nozzle sprays straight, or if a mold makes perfect parts. Poor tolerance or surface finish can cause early failure or bad performance.

Surface Finish Levels and Common Applications

Different Ra values define how smooth a surface is. This chart shows typical finishes and where they are used.

| Ra (µm) | Description | Common Use |

|---|---|---|

| 3.2 | Rough | Castings, rough milling |

| 1.6 | Normal machined finish | General turning/milling |

| 0.8 | Fine machined | Precision shafts |

| 0.4 | Very smooth | Molds, sealing faces |

| 0.2 | Mirror-like | Sealing rings, optics |

Frequently Asked Questions About Tolerance & Surface Finish

These are the most common questions customers ask when preparing drawings or placing precision part orders. Clear answers help you avoid costly mistakes.

Q1: What if I don’t specify the tolerance?

Standard machining tolerances will be used, which may not meet your exact needs.

Q2: How do I know what Ra I need?

It depends on the part’s function. Contact us if unsure—we’ll recommend the best level.

Q3: Can Retop achieve Ra 0.2µm?

Yes, we offer precision polishing for ultra-smooth finishes.

Q4: Can I request different tolerances for different parts of the same drawing?

Yes, you can specify different tolerances for different features. Just make sure they are clearly labeled on the drawing.

Q5: What happens if my drawing only shows dimensions but no Ra or tolerance?

We will follow standard machining and finishing practices, but results may not match your performance expectations. Always specify if it’s critical.

Q6: How does surface finish affect tool performance or lifespan?

Smoother surfaces reduce friction and wear, which improves sealing, flow, and overall lifespan—especially for high-precision components.