What is Dimensional Tolerance?

Dimensional tolerance refers to the permissible limit or limits of variation in a physical dimension—such as length, diameter, or thickness—of a manufactured part. It defines how much deviation is acceptable from the nominal dimension without compromising the function or interchangeability of the part.

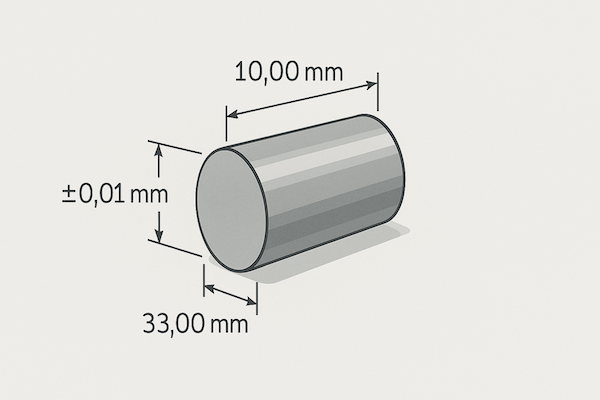

For example, a carbide rod with a nominal diameter of 10.00 mm ±0.01 mm can have a diameter anywhere between 9.99 mm and 10.01 mm and still be considered acceptable.

Why is Dimensional Tolerance Important?

In high-precision industries like aerospace, automotive, medical, and electronics, parts must fit and function within extremely tight constraints. Even slight deviations can lead to assembly issues, performance degradation, or product failure. That’s why dimensional tolerances are critical for ensuring:

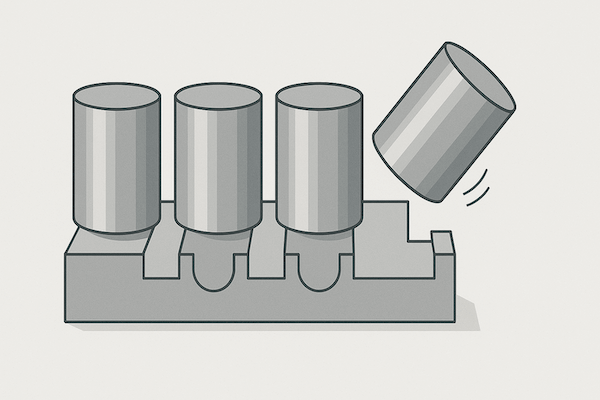

Interchangeability of components

Reliable performance under stress

Consistency in mass production

Minimized post-processing time

The Role of Dimensional Tolerance in Tungsten Carbide Tools

Tungsten carbide, known for its exceptional hardness and wear resistance, is widely used to manufacture cutting tools, wear parts, dies, and nozzles. Due to its brittleness and high hardness, carbide parts are typically ground to final dimensions rather than machined.

In the case of carbide tools, dimensional tolerances directly affect:

Cutting accuracy

Tool life and repeatability

Mounting compatibility with tool holders or molds

Thermal expansion gaps and stress distribution

Common Examples:

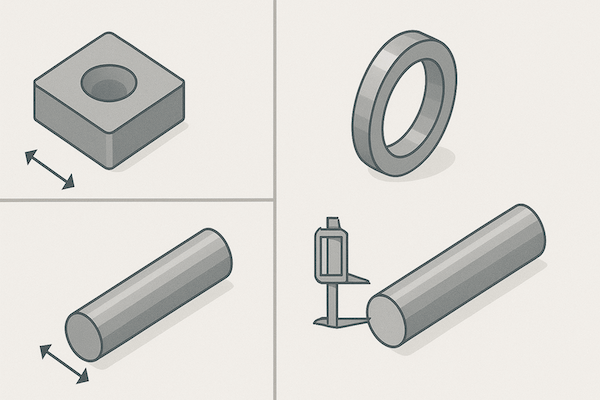

Carbide Inserts: Tolerances in thickness or corner radii affect how inserts sit in holders and the precision of the cutting edge.

Seal Rings: Poor tolerance can lead to sealing failure in pumps or compressors.

Carbide Rods or Blanks: Used in end mills and drills, precise diameters are required to fit standard grinding machines and tool holders.

Tolerance Grades and Standards

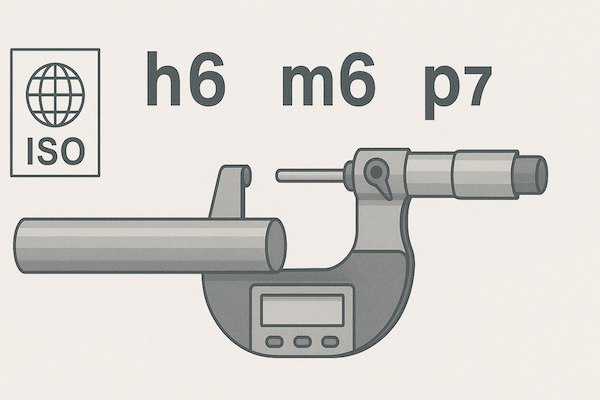

Dimensional tolerances for tungsten carbide tools are usually based on international standards such as:

ISO 2768 – for general tolerances

ISO 286 / DIN ISO 286 – fits and tolerances for cylindrical parts

ISO 3295 / ISO 13399 – for cutting tools and inserts

High-precision carbide tools often use tolerance grades such as h6, h7, m6, etc., with tolerances as tight as ±0.001 mm for critical applications.

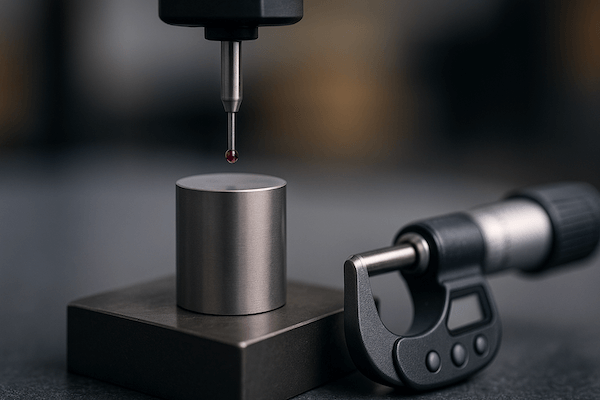

Manufacturing and Inspection

Due to the high hardness of tungsten carbide, achieving tight tolerances requires advanced grinding, lapping, and sometimes polishing. Inspection methods include:

Digital micrometers and calipers

Coordinate Measuring Machines (CMMs)

Optical comparators and laser scanners

Consistent dimensional control ensures high-quality tools that meet exacting customer requirements across various industries.

Conclusion

Dimensional tolerance is a cornerstone of precision engineering—especially when it comes to tungsten carbide tools. Whether it’s a cutting insert, a nozzle, or a seal ring, strict adherence to tolerance standards guarantees performance, reliability, and long-term wear resistance. As applications demand ever-higher precision, the role of dimensional tolerance in carbide tooling continues to grow in importance.