In industries worldwide, sustainability is becoming a key focus.

As companies search for eco-friendly alternatives, tungsten carbide bushings have gained recognition for their environmental benefits.

This article will explore the eco-friendly advantages of using tungsten carbide bushings, focusing on their durability, energy efficiency, recyclability, and low maintenance.

Advantage 1: Durability and Longevity

Tungsten carbide bushings are known for their exceptional durability.

Unlike softer materials, tungsten carbide is highly resistant to wear and tear, meaning the bushings last much longer.

For instance, in aerospace and oil and gas industries, components made from tungsten carbide can endure for several years without needing replacements.

This reduces the frequency of manufacturing new parts, which cuts down on the resources needed for production.

Example:

In a manufacturing plant, machinery using tungsten carbide bushings may run for thousands of hours with minimal wear, whereas machines using conventional steel bushings might need new parts every year.

This extended lifespan means fewer parts need to be disposed of, reducing overall material waste.

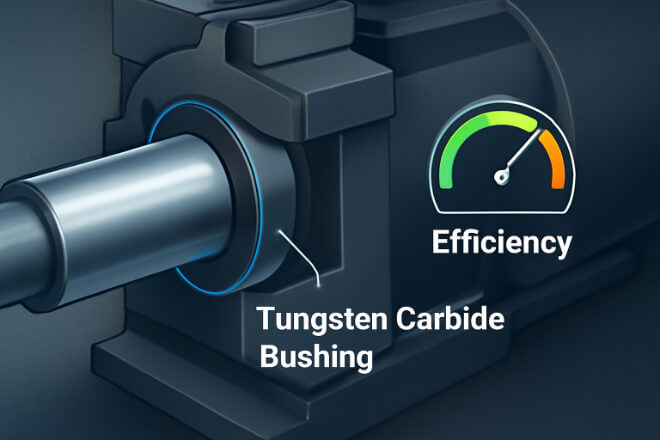

Advantage 2: Energy Efficiency

The low friction properties of tungsten carbide help machinery run smoothly, requiring less energy.

Machines with tungsten carbide bushings operate more efficiently, which can reduce energy consumption significantly.

In industries like automotive manufacturing, reducing energy use is vital for minimizing costs and reducing carbon emissions.

Example:

A pump system using tungsten carbide bushings consumes less energy than a system with standard bushings, resulting in lower electricity bills and a reduced environmental footprint.

The savings in energy consumption over the years can be significant, helping companies meet their sustainability goals.

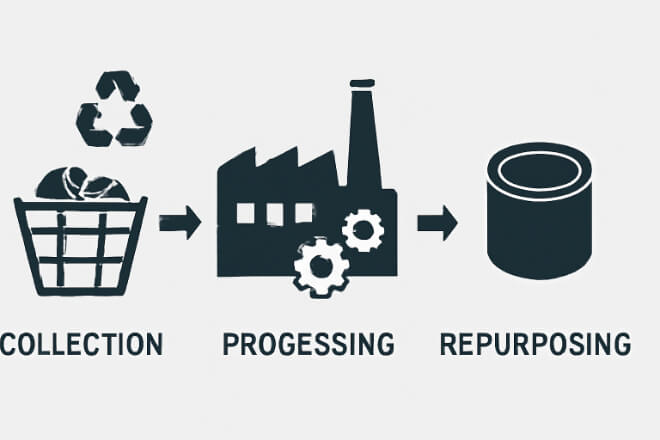

Advantage 3: Recyclability and Sustainability

Tungsten carbide is a highly recyclable material. After the bushings reach the end of their life cycle, they can be collected and repurposed.

The recycling process for tungsten carbide is efficient, reducing the need for new raw materials.

This is particularly important in industries where raw material extraction is energy-intensive and harmful to the environment.

Example:

In a mining operation, used tungsten carbide bushings can be recycled and refashioned into new parts, reducing the need for mining new tungsten and limiting the environmental impact associated with raw material extraction.

Advantage 4: Reduced Material Waste

Tungsten carbide’s high wear resistance reduces the amount of material waste generated in production and throughout the part’s life.

This is because parts made from tungsten carbide have a longer service life and experience less wear.

For manufacturers, this means fewer replacements and less waste generated from discarded parts.

Example:

In the pump industry, replacing worn-out bushings with tungsten carbide means fewer discarded parts and less scrap material.

This is in contrast to traditional materials, which may need frequent replacements, creating more waste and requiring more resources to produce new parts.

Advantage 5: Low Maintenance and Reduced Toxicity

Tungsten carbide bushings require minimal maintenance, unlike traditional materials that often need regular lubrication or cleaning with toxic chemicals.

The high resistance to wear and corrosion reduces the need for ongoing maintenance, which can otherwise involve harmful chemicals that are damaging to the environment.

Example:

In a factory setting, machines using tungsten carbide bushings do not require frequent cleaning with harsh chemicals.

Which lowers the risk of contamination and reduces the release of toxic substances into the environment.

Conclusion

Tungsten carbide bushings offer significant environmental benefits, including durability, energy efficiency, recyclability, and low maintenance.

By using tungsten carbide, industries can reduce waste, save energy, and contribute to a more sustainable future.

As companies continue to prioritize eco-friendly practices, integrating tungsten carbide into their operations is a step toward achieving greener manufacturing processes.

If you want to know more details about any company, please feel free to contact us.