El petróleo y gas industry works in some of the toughest environments in the world. Machines run under high pressure, extreme temperature, and in direct contact with abrasive fluids.

In these conditions, every small part must be strong and reliable. One of the most important parts is the tungsten carbide seal ring.

Seal rings may look simple, but they prevent leaks, protect pumps and compressors, and improve safety. Tungsten carbide, with its hardness and durability, makes these rings ideal for oil and gas operations.

This article explains the main applications of tungsten carbide seal rings in oil and gas, their benefits, and why they are the preferred choice for decision-makers in this industry.

Why Tungsten Carbide Seal Rings Matter in Oil and Gas

The oil and gas industry faces unique challenges:

High pressure in drilling and pumping systems

Abrasive fluids like mud and sand in drilling wells

Corrosive chemicals in refining and processing

Extreme heat in turbines and compressors

Tungsten carbide seal rings are designed to resist these forces. They provide longer service life, better sealing, and lower risk of failure compared with standard materials like steel or ceramics.

Key Properties for Oil and Gas Applications

1). Dureza y Resistencia al desgaste

Tungsten carbide is almost as hard as diamond. This allows the seal rings to resist wear from sand, mud, and other abrasive particles found in drilling fluids.

2). Resistencia a la corrosión

Nickel-bonded tungsten carbide rings resist corrosion from seawater and acids, making them perfect for offshore and refining systems.

3). High Strength

Cobalt-bonded tungsten carbide rings provide tenacidad and handle the shock and pressure changes in drilling pumps.

4) Estabilidad térmica

Seal rings keep their hardness and shape even in hot turbines and compressors.

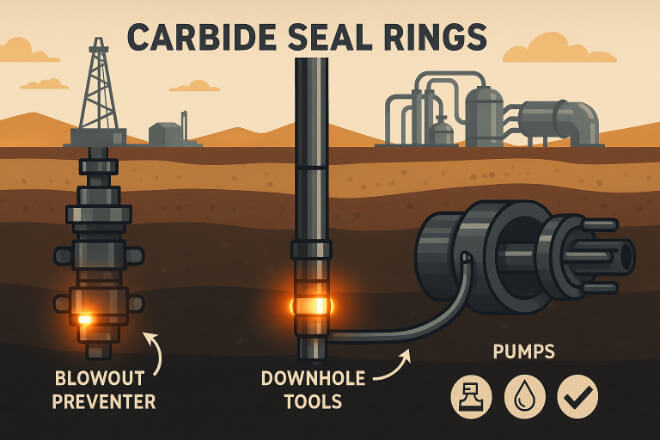

Applications in Drilling Operations

- Bombas de lodo

Mud pumps circulate drilling fluid under high pressure. Tungsten carbide seal rings prevent leaks and resist abrasion from sand and rock.

- Downhole Tools

Tools deep inside wells face abrasive mud and high temperature. Seal rings made from cobalt-bonded tungsten carbide survive these extreme loads.

- Blowout Preventers

Critical safety equipment requires strong sealing. Tungsten carbide rings ensure reliability under emergency conditions.

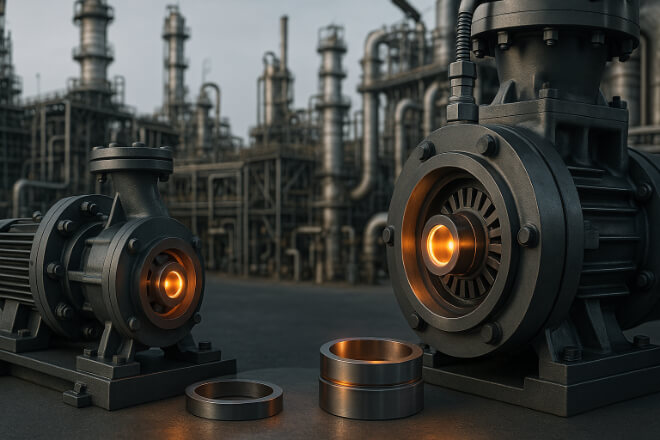

Applications in Production and Refining

- Pumps in Refineries

Refinery pumps handle corrosive chemicals. Nickel-bonded seal rings resist acid attack and reduce failures.

- Compressors

Gas compressors run at high speed and temperature. Tungsten carbide rings reduce friction and improve sealing, ensuring safe operations.

Valves control flow in pipelines. Tungsten carbide seal rings provide tight seals, even with corrosive or abrasive fluids.

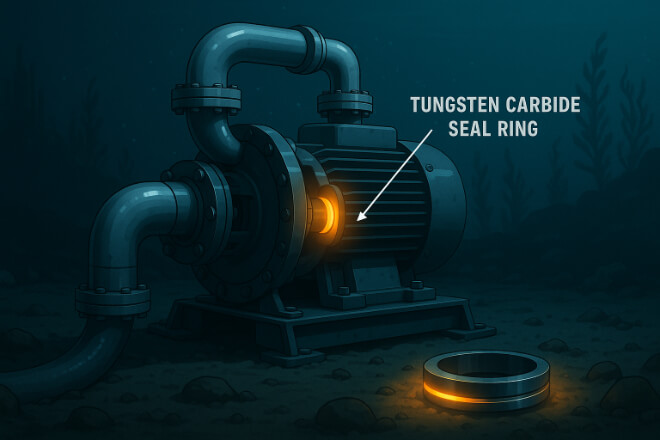

Offshore and Subsea Applications

Subsea Pumps

Located on the seabed, these pumps must handle seawater and extreme pressure. Nickel-bonded tungsten carbide seal rings prevent corrosion and leaks.

Plataformas offshore

Pumps and compressors on offshore rigs face both seawater and drilling fluids. Custom seal rings improve safety and extend service life.

Benefits for the Oil and Gas Industry

Longer Service Life: Withstands abrasion and corrosion, reducing replacement needs.

Improved Safety: Strong seals reduce the risk of leaks and accidents.

Lower Maintenance Costs: Fewer breakdowns mean less downtime and repair work.

Stronger ROI: Higher upfront cost is balanced by long-term savings.

Comparación con otros materiales

| Material | Fortalezas | Weaknesses |

|---|---|---|

| Stainless Steel | Low cost, easy to make | Poor wear resistance, weak against acids |

| Silicon Carbide | Buena resistencia a la corrosión | Brittle, breaks under shock |

| Cerámica | High hardness, good heat resistance | Fragile, cracks under load |

| Carburo de tungsteno | Excellent wear, corrosion, and heat resistance | Costo inicial más alto |

Estudios de caso

Offshore Drilling Platform

Using nickel-bonded tungsten carbide rings in seawater pumps doubled service life compared with stainless steel seals.

Refinery Pump Systems

Switching from ceramics to tungsten carbide reduced failures and cut maintenance costs by 40%.

Gas Compressors

Cobalt-bonded rings provided better toughness under pressure, improving uptime.

How to Select the Right Tungsten Carbide Seal Ring for Oil and Gas

1). Binder Type:

Nickel for corrosion resistance

Cobalt for tenacidad and shock resistance

2). Operating Conditions:

Pressure, speed, and fluid type must be reviewed

3). Industry Standards:

Choose seals that meet petróleo y gas safety codes

4). Supplier Reliability:

Work with trusted suppliers

Who offer testing and ISO certification

Estrategia de mantenimiento y reemplazo

Even tungsten carbide needs inspection:

Regular checks: Look for cracks, scratches, or corrosion marks

Replacement timing: Avoid waiting for full failure

Recycling: Worn rings can be recycled to reduce cost

Cost and ROI for Oil and Gas Companies

Upfront investment: Higher than standard materials

Savings: Fewer replacements, lower downtime, safer operations

ROI: Strong, especially in offshore and high-pressure systems

Conclusión

In the oil and gas industry, where conditions are some of the harshest, tungsten carbide seal rings provide unmatched performance.

Their resistance to wear, corrosion, and heat makes them the material of choice for pumps, compressors, valves, and subsea equipment.

For decision-makers, investing in tungsten carbide means longer uptime, fewer failures, safer operations, and stronger financial returns.

Si desea conocer más detalles sobre alguna empresa, no dude en contactarnos. Contáctanos.