Los sistemas de energía renovable, como turbinas eólicas, plantas hidroeléctricas, parques solares con bombas y sistemas geotérmicos, funcionan en condiciones ambientales difíciles.

Sus componentes deben funcionar durante años con un mantenimiento mínimo para mantener la producción de energía eficiente y rentable.

Un componente crítico es el anillo de selloEn bombas, turbinas y compresores, los sellos evitan fugas de fluidos, protegen los cojinetes y garantizan la eficiencia energética.

Entre los materiales disponibles, los anillos de sello de carburo de tungsteno ofrecen un rendimiento superior para equipos de energía renovable.

¿Por qué son importantes los anillos de sellado en los sistemas de energía renovable?

Las fallas del sello pueden:

Provoca fugas de líquidos en los sistemas hidráulicos o de refrigeración.

Aumenta el tiempo de inactividad, reduciendo el consumo de energía.

Genera costes de mantenimiento adicionales y riesgos de seguridad.

Menor eficiencia de los equipos, desperdiciando energía renovable.

Los sellos confiables garantizan un funcionamiento continuo y un mejor retorno de la inversión para proyectos eólicos, hidroeléctricos, solares y geotérmicos.

Propiedades clave de los anillos de sellado de carburo de tungsteno

El carburo de tungsteno es un compuesto de tungsteno y carbono, unido con cobalto o níquel. Sus principales propiedades incluyen:

Extremo dureza → Resiste el desgaste por partículas abrasivas.

Alta resistencia a la compresión → Maneja altas cargas y presiones.

Resistencia a la corrosión → Protege contra el agua, productos químicos o vapor.

Estabilidad térmica → Mantiene el rendimiento en sistemas geotérmicos o de turbinas calientes.

Larga vida útil → Reduce residuos y mantenimiento.

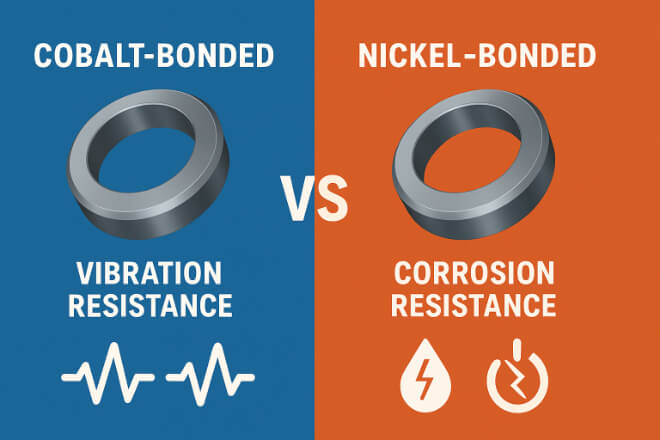

Carburo de tungsteno unido con cobalto vs. carburo de tungsteno unido con níquel

1) Carburo de tungsteno unido con cobalto

Más tenacidad y resistencia al impacto.

Ideal para turbinas eólicas o sistemas hidroeléctricos con vibración.

2) Carburo de tungsteno unido con níquel

Superior Resistencia a la corrosión.

Ideal para equipos geotérmicos y renovables marinos donde hay agua y productos químicos.

Ventajas sobre otros materiales de sellado

| Característica | Carburo de tungsteno | Cerámico | Acero |

|---|---|---|---|

| Resistencia al desgaste | Excelente | Moderado | Pobre |

| Resistencia a la corrosión | Alto (calidades de níquel) | Muy bien | Bajo |

| Tenacidad | Alto, resistente a golpes. | Bajo, quebradizo | Moderado |

| Rendimiento térmico | Excelente a altas temperaturas | Bien | Moderado |

| Vida útil | De larga duración | Moderado | Corto |

Aplicaciones en equipos de energía renovable

Los anillos de sellado de carburo de tungsteno se utilizan en:

turbinas eólicas → Cajas de cambios y sistemas hidráulicos.

Plantas hidroeléctricas → Bombas y turbinas que manejan agua con escombros.

Parques solares → Bombas de refrigeración y circulación.

Plantas geotérmicas → Bombas y compresores de alta temperatura.

Sistemas de energía marina → Convertidores de energía de mareas y olas expuestos al agua de mar.

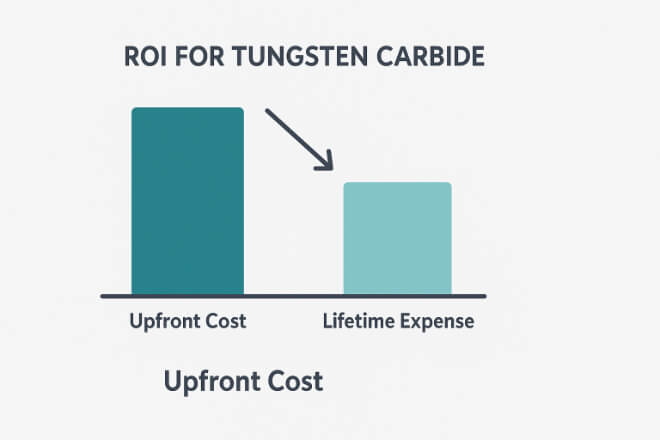

Costo vs. valor a largo plazo

Si bien los anillos de sello de carburo de tungsteno cuestan más por adelantado:

Duran más, reduciendo el tiempo de inactividad y el mantenimiento.

Previenen fugas que pueden dañar equipos renovables costosos.

Su durabilidad conduce a un mejor retorno de la inversión durante la vida útil del proyecto.

Beneficios ambientales

Material reciclable → Los anillos desgastados se pueden recuperar y reutilizar.

Menos desperdicio → Menos reemplazos significan una menor eliminación en vertederos.

Mayor eficiencia → Prevenir fugas ahorra energía y reduce las emisiones.

Para las empresas de energía renovable comprometidas con la sostenibilidad, el carburo de tungsteno se alinea con los objetivos operativos ecológicos.

Mejores prácticas para elegir y utilizar anillos de sellado de carburo de tungsteno

Evaluar el entorno operativo → ¿Agua corrosiva? ¿Vibración alta? Elija el aglutinante adecuado.

Trabaje con proveedores experimentados → Garantizar especificaciones correctas para los sistemas renovables.

Instalar correctamente → Evite rayones o desalineaciones que provoquen fugas.

Inspeccionar regularmente → Evite fallas antes de que causen tiempos de inactividad costosos.

Reciclar anillos desgastados → Apoye la fabricación circular y la sostenibilidad.

Conclusiones clave para los responsables de la toma de decisiones

Los anillos de sello de carburo de tungsteno garantizan durabilidad, eficiencia y sostenibilidad en equipos de energía renovable.

Elija unión con níquel para entornos con alta corrosión y unión con cobalto para sistemas con alta vibración.

El mayor costo inicial se justifica por los ahorros a largo plazo y los beneficios ambientales.

Los sellos confiables mejoran la producción de energía y la protección de los equipos en sistemas eólicos, hidroeléctricos, solares, geotérmicos y marinos.

Conclusión

Los equipos de energía renovable deben funcionar de forma fiable durante décadas en condiciones exigentes. Los anillos de sellado de carburo de tungsteno proporcionan la dureza, la resistencia y la resistencia a la corrosión necesarias para estos sistemas críticos.

Para los tomadores de decisiones, invertir en anillos de sello de carburo de tungsteno favorece la eficiencia, el ahorro de costos y la responsabilidad ambiental, lo que los convierte en la opción inteligente para las operaciones de energía renovable.

Si desea conocer más detalles sobre alguna empresa, no dude en contactarnos. Contáctanos.