Pumps are critical components in industries like petróleo y gas, power generation, chemical processing, and marine operations.

A single leak can cause costly downtime, environmental risks, and safety hazards. To avoid these issues, mechanical seals must be durable and reliable.

Tungsten carbide seal rings are one of the most trusted solutions for leak-free pump operation. This article explains their properties, advantages, applications, and best practices for decision-makers.

Why Leak-Free Pump Operation Matters

Prevents fluid loss → Protects resources and reduces waste.

Maintains efficiency → Pumps perform better without pressure loss.

Reduces maintenance costs → Fewer failures mean fewer repairs.

Protects the environment → Prevents spills of hazardous materials.

Ensures safety → Avoids dangerous leaks near operators or equipment.

Propiedades de los anillos de sellado de carburo de tungsteno

El carburo de tungsteno es un compuesto de tungsteno y carbono, unido con cobalto o níquel. Sus propiedades incluyen:

Extremo dureza → Resiste el desgaste por fricción y partículas.

Alta resistencia a la compresión → Handles heavy loads without cracking.

Resistencia a la corrosión → Works well with chemicals, seawater, and oils.

Estabilidad térmica → Maintains sealing performance under high heat.

Estabilidad dimensional → Ensures precise sealing over long periods.

These properties help pumps stay leak-free under tough conditions.

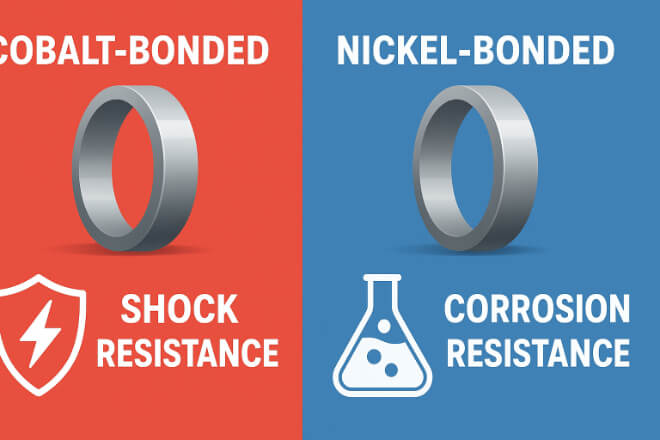

Carburo de tungsteno unido con cobalto vs. carburo de tungsteno unido con níquel

1) Carburo de tungsteno unido con cobalto

Best for vibration-heavy or high-shock pumps.

Common in oilfield and mining operations.

2) Carburo de tungsteno unido con níquel

Superior Resistencia a la corrosión.

Ideal for chemical plants, marine pumps, and wastewater systems.

Choosing the right binder ensures long service life and reliable sealing.

Ventajas sobre otros materiales de sellado

| Característica | Carburo de tungsteno | Cerámico | Acero |

|---|---|---|---|

| Resistencia al desgaste | Excellent for abrasives | Moderado | Pobre |

| Resistencia a la corrosión | Alto (calidades de níquel) | Muy bien | Bajo |

| Tenacidad | Alto, resistente a golpes. | Bajo, quebradizo | Moderado |

| Rendimiento térmico | Excelente a altas temperaturas | Bien | Moderado |

| Vida útil | De larga duración | Moderado | Corto |

Applications in Pump Systems

Los anillos de sellado de carburo de tungsteno se utilizan en:

Chemical pumps → Handle aggressive fluids safely.

Bombas marinas → Resist seawater corrosion.

Oil and gas pumps → Prevent leaks under pressure.

Wastewater pumps → Manage abrasive and corrosive fluids.

Bombas de refrigeración de centrales eléctricas → Maintain leak-free operation for critical systems.

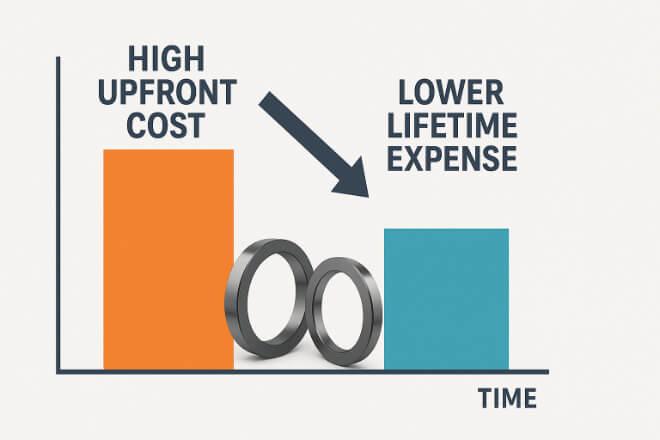

Costo vs. valor a largo plazo

While tungsten carbide rings cost more upfront:

Menos reemplazos → Menores costos de repuestos.

Tiempo de inactividad reducido → Increases production efficiency.

Mayor vida útil del equipo → Protects pump components.

Mejor retorno de la inversión → Long-term savings outweigh initial price.

Environmental and Safety Benefits

Leak prevention → Avoids contamination and environmental damage.

Material reciclable → Supports sustainable practices.

Energy efficiency → Preventing leaks reduces wasted energy.

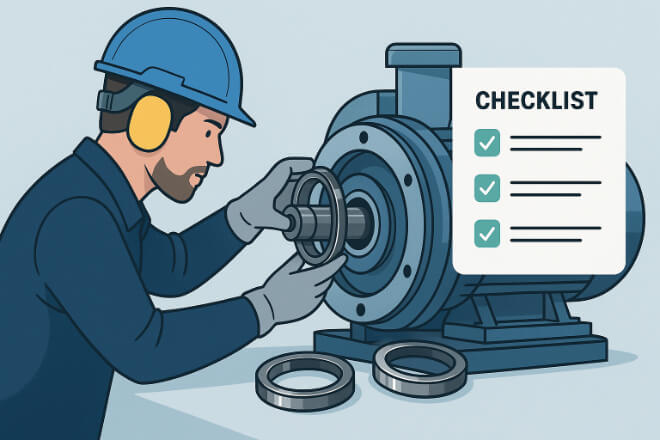

Best Practices for Leak-Free Performance

Seleccione la carpeta adecuada → Match to chemical and mechanical conditions.

Ensure proper installation → Evite rayones o desalineaciones.

Utilice una lubricación adecuada → Reduces friction and heat.

Inspeccionar regularmente → Catch wear early before leaks start.

Partner with reliable suppliers → Asegúrese de que la calidad del material y las especificaciones sean correctas.

Conclusiones clave para los responsables de la toma de decisiones

Tungsten carbide seal rings ensure leak-free pump operation under tough conditions.

Choosing the correct grade (nickel or cobalt) is critical for performance.

Their durability, recyclability, and efficiency lower costs and environmental risks.

Investing in tungsten carbide protects pumps and improves ROI.

Conclusión

For pumps in chemical plants, power stations, marine systems, and oilfields, tungsten carbide seal rings are a proven choice for preventing leaks.

Their hardness, corrosion resistance, and strength deliver long-term performance, reduced downtime, and environmental protection.

For decision-makers, selecting tungsten carbide is a strategic investment in safety, sustainability, and cost efficiency.

Si desea conocer más detalles sobre alguna empresa, no dude en contactarnos. Contáctanos.