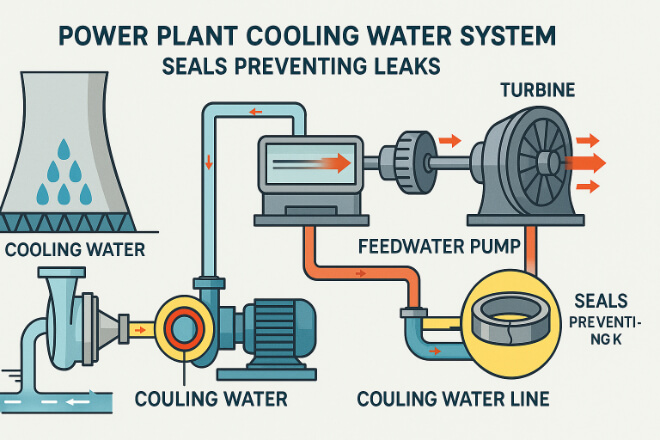

Power plants rely on cooling water systems to manage heat and keep turbines, pumps, and generators running safely.

Any leak or failure in these systems can lead to downtime, efficiency loss, or environmental damage.

Tungsten carbide seal rings are one of the most reliable materials for pumps and compressors in cooling water systems.

This article explains why they are essential, their benefits, and how to use them effectively.

Why Cooling Water Systems Need Reliable Seals

Prevent leaks → Protect equipment and reduce water loss.

Maintain efficiency → Proper seals help pumps operate at full performance.

Reducir el tiempo de inactividad → Reliable seals minimize unplanned maintenance.

Avoid contamination → Prevents cooling water from mixing with other fluids.

Protect the environment → Stops harmful discharges into natural water sources.

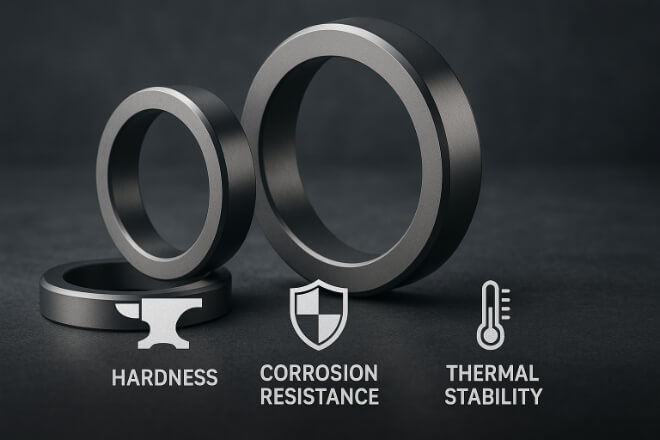

Propiedades clave de los anillos de sellado de carburo de tungsteno

Tungsten carbide is a compound of tungsten and carbon, bonded with cobalt or nickel. It offers:

Extremo dureza → Resists abrasion from particles in water.

Alta resistencia a la compresión → Handles high pressure in large pumps.

Resistencia a la corrosión → Works well with treated or brackish water.

Estabilidad térmica → Maintains sealing performance under temperature changes.

Larga vida útil → Fewer replacements and lower maintenance costs.

Carburo de tungsteno unido con cobalto vs. carburo de tungsteno unido con níquel

1) Carburo de tungsteno unido con cobalto

Mayor que tenacidad for pumps exposed to vibration or shock.

Common in large turbine cooling systems.

2) Carburo de tungsteno unido con níquel

Superior Resistencia a la corrosión.

Ideal for brackish or chemically treated water.

Ventajas sobre otros materiales de sellado

| Característica | Carburo de tungsteno | Cerámico | Acero |

|---|---|---|---|

| Resistencia al desgaste | Excellent for abrasives | Moderado | Pobre |

| Resistencia a la corrosión | Alto (calidades de níquel) | Muy bien | Bajo |

| Tenacidad | Alto, resistente a golpes. | Bajo, quebradizo | Moderado |

| Rendimiento térmico | Excelente a altas temperaturas | Bien | Moderado |

| Vida útil | De larga duración | Moderado | Corto |

Applications in Power Plant Cooling Water Systems

Los anillos de sello de carburo de tungsteno se utilizan ampliamente en:

Main cooling water pumps → Ensure reliable, leak-free operation.

Circulating pumps → Maintain water movement for turbine efficiency.

Auxiliary systems → Protect small pumps in control circuits.

Brackish water systems → Resist corrosion in coastal plants.

Backup generators → Provide sealing under varying temperatures and pressures.

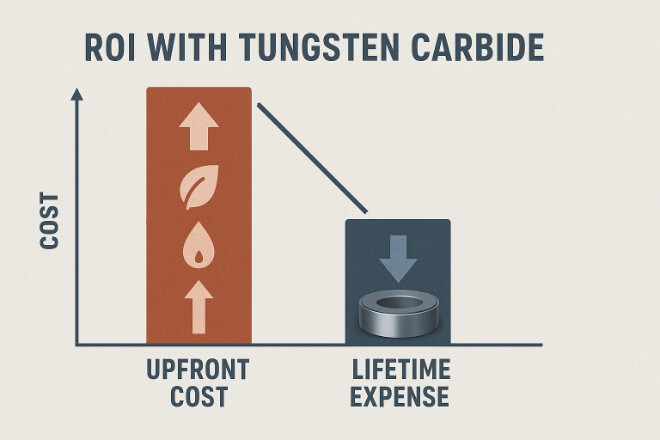

Costo vs. valor a largo plazo

Although tungsten carbide seal rings cost more upfront:

Reducir el tiempo de inactividad → Fewer failures mean less lost production.

Lower maintenance → Longer service life reduces labor and spare parts.

Protect equipment → Prevents damage to expensive pumps and turbines.

Improve ROI → Long-term savings offset initial costs.

Environmental and Safety Benefits

Leak prevention → Protects local water sources and ecosystems.

Material reciclable → Supports power plants’ sustainability goals.

Efficient performance → Reduces wasted energy in pumps and compressors.

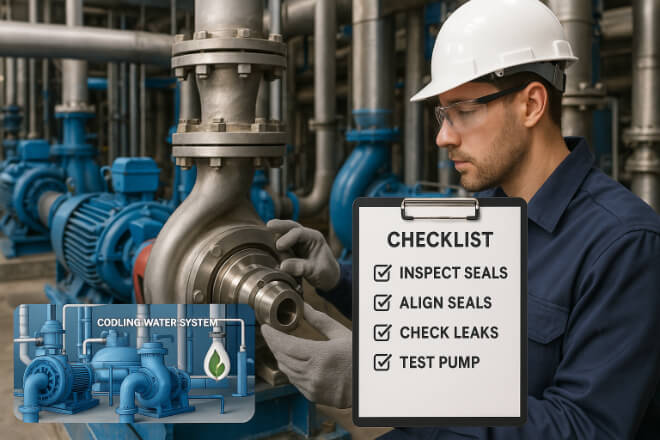

Mejores prácticas para el uso de anillos de sellado de carburo de tungsteno

Elige la carpeta adecuada → Nickel for brackish or chemical-rich water, cobalt for vibration-heavy pumps.

Inspect seals regularly → Detectar desgaste temprano para prevenir fallas.

Ensure proper installation → Avoid scratches or misalignment during assembly.

Maintain proper lubrication → Prevent dry running that can damage seals.

Work with trusted suppliers → Get quality materials and accurate specifications.

Conclusiones clave para los responsables de la toma de decisiones

Tungsten carbide seal rings are the best choice for power plant cooling water systems.

They combine durability, Resistencia a la corrosión, y tenacidad for long-term performance.

Higher upfront cost delivers better ROI through reduced downtime and maintenance.

Proper selection and care ensure reliable, leak-free operation.

Conclusión

Power plant cooling water systems demand seals that can perform under pressure, temperature shifts, and corrosive conditions.

Tungsten carbide seal rings deliver the strength and reliability required to keep operations efficient and safe.

For decision-makers, investing in tungsten carbide ensures long-term savings, environmental protection, and operational reliability.

Si desea conocer más detalles sobre alguna empresa, no dude en contactarnos. Contáctanos.