Modern ships depend on ballast water for stability and cooling circuits to protect engines and auxiliary equipment.

These systems constantly pump raw seawater, which is salty, abrasive, and sometimes contaminated with sediment. Small leaks or seal failures can interrupt operations, increase maintenance costs, or breach environmental rules.

For these demanding tasks, anillos de sellado de carburo stand out as a reliable choice. They combine dureza, Resistencia a la corrosión, and long-term stability that conventional materials often cannot match.

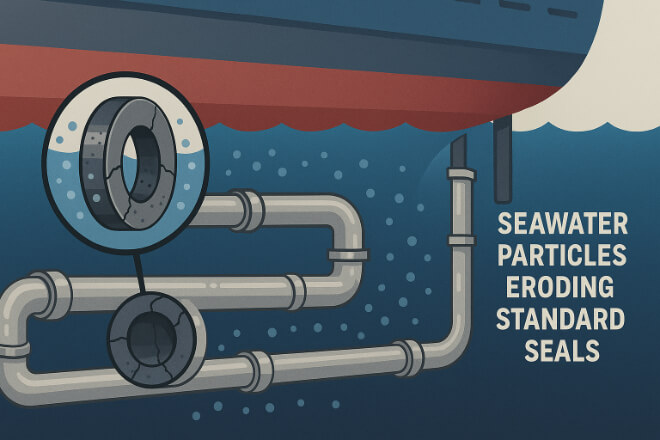

Marine Operating Challenges That Damage Seals

Saltwater corrosion degrades ordinary metal seals over time.

Fine sand and debris in ballast tanks act like sandpaper on sealing surfaces.

Pressure changes during loading/unloading put stress on pump components.

Continuous voyages limit opportunities for maintenance or repairs.

Because of these factors, a stronger, more stable sealing solution is essential.

Unique Advantages of Carbide Seal Rings

1). Exceptional Dureza

Carbide is one of the hardest engineered materials, preventing surface scratches and wear.

2). Reliable Corrosion Protection

Nickel-bonded grades resist seawater’s salt content and biofouling chemicals.

3). Strength Under Vibration

Cobalt-bonded grades withstand vibration and mechanical shock from ship engines and waves.

4) Resistencia al calor

Carbide retains its shape and sealing ability even under fluctuating engine temperatures.

5). Extended Lifespan

Longer service intervals reduce costly dry-dock repairs and unplanned downtime.

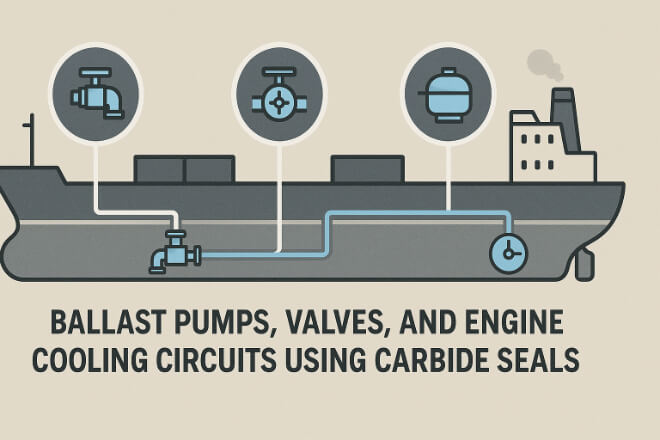

Where They Are Used on Vessels

1). Ballast Handling

Ballast Pumps: Carbide seals keep pumps leak-free as tanks fill or discharge.

Ballast Valves: Seals maintain tight closures, preventing invasive species transfer.

Treatment Modules: Units disinfecting ballast water rely on carbide rings for tight sealing under chemical exposure.

2). Cooling Circuits

Engine Cooling Pumps: Prevent leakage in high-flow seawater pumps.

Heat Exchangers: Seals preserve cooling efficiency and protect sensitive engine parts.

Auxiliary Systems: Generators and hydraulic coolers benefit from reliable carbide sealing.

| Beneficio | Impact |

|---|---|

| Durabilidad | Survives abrasive particles and saltwater exposure for longer periods. |

| Maintenance Savings | Fewer replacements lower parts and labor costs during port calls. |

| Regulatory Compliance | Helps meet ballast water management standards and environmental rules. |

| Operational Reliability | Stable seals support uninterrupted voyages and cargo schedules. |

| Seguridad | Prevents leaks that could damage engines or pollute marine ecosystems. |

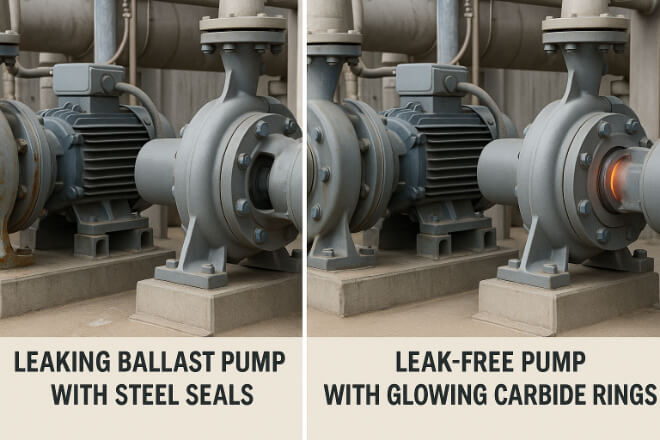

Real-World Example

A container line replaced traditional steel seals with nickel-bonded carbide rings in its ballast pumps.

After a year, maintenance records showed 40% fewer leaks and a noticeable reduction in emergency part orders.

Another fleet upgraded cooling pumps on auxiliary generators to carbide seals, improving uptime during transoceanic voyages.

Selection Tips for Marine Applications

Assess Water Quality: Consider sediment content and salinity of operating regions.

Choose Binder Wisely: Nickel for Resistencia a la corrosión, cobalt for vibration and shock.

Specify Surface Finish: Polished carbide reduces friction and heat buildup.

Verify Supplier Experience: Select ISO-certified vendors familiar with marine standards.

Maintenance Practices for Longer Life

Inspect seals during scheduled port maintenance or dry dock.

Replace rings proactively to avoid in-service failures.

Stock spare carbide seals for critical pumps and heat exchangers.

Recycle used carbide parts to reduce waste and costs.

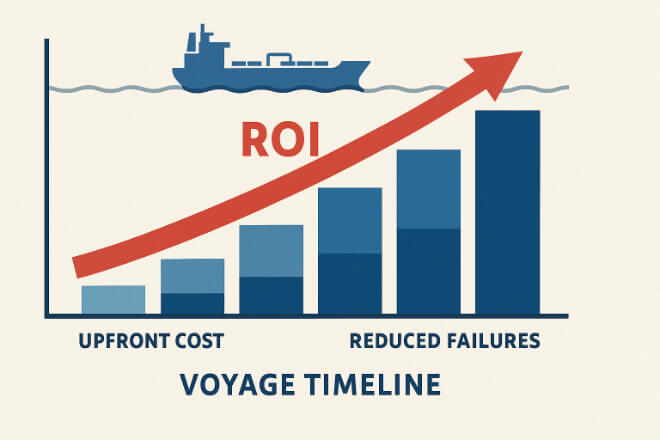

Consideraciones sobre costos y retorno de la inversión

Although carbide rings cost more upfront, they:

Extend service intervals up to 5–10× compared with steel seals.

Cut emergency repair costs by preventing sudden leaks.

Improve vessel scheduling reliability, saving demurrage fees.

Deliver a stronger return on investment through fewer breakdowns.

Environmental and Compliance Advantages

International ballast water rules and marine pollution laws are strict. Reliable carbide sealing minimizes the risk of accidental discharges, protecting marine ecosystems and helping owners avoid fines or detentions.

Conclusión

Carbide seal rings are an essential upgrade for marine ballast water and cooling systems. Their dureza, Resistencia a la corrosión, and long-term reliability protect ships from costly downtime and regulatory penalties.

For ship operators and fleet managers, carbide seals provide operational confidence, safety, and cost savings—making them a smart investment in today’s competitive marine industry.

Si desea conocer más detalles sobre alguna empresa, no dude en contactarnos. Contáctanos.