In demanding industrial systems — such as pumps, compressors, turbines, and chemical mixers — bushings play a key role in keeping shafts stable and reducing wear.

When exposed to high pressure, temperature, and friction, material selection becomes critical to equipment reliability.

Two materials often compared are tungsten carbide and ceramic bushings. Both are hard and corrosion-resistant, but their performance under stress differs significantly.

This article explains how each performs in mechanical, thermal, and chemical conditions — helping engineers and managers decide which offers better long-term value for their operations.

Understanding the Materials

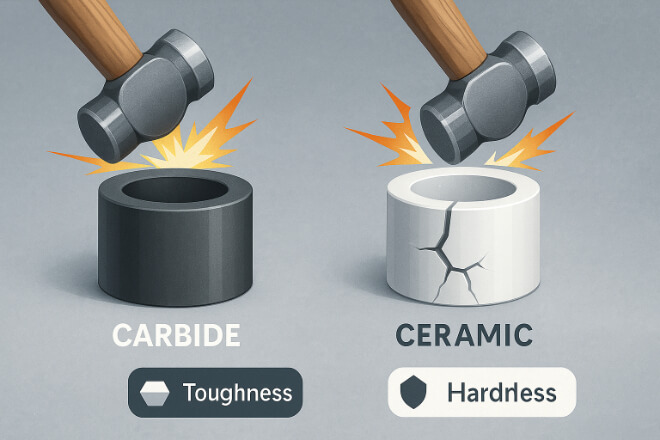

Tungsten carbide (WC) is a metal–ceramic composite made from tungsten and carbon particles, typically bonded with cobalt or nickel.

It combines metallic tenacidad with ceramic hardness, giving it strength and resilience under high loads.

Ceramic bushings, commonly made from materials such as silicon nitride or alumina, are extremely hard and lightweight. They are excellent in corrosion resistance but are brittle under impact or vibration.

Both materials are used in modern industries, but their structural behavior under stress is where the biggest differences emerge.

Mechanical Property Comparison

| Propiedad | Carburo de tungsteno | Cerámico |

|---|---|---|

| Dureza (HRA) | 88–92 | 85–90 |

| Resistencia a la compresión (MPa) | 4000+ | 2000–3000 |

| Fracture Toughness (MPa·m½) | 8–15 | 3–5 |

| Densidad (g/cm³) | 14.5 | 3.5–4.5 |

| Elastic Modulus (GPa) | 550–650 | 300–400 |

From this comparison, tungsten carbide offers higher strength and tenacidad, while ceramics are lighter but more fragile under impact.

Performance Under Mechanical Stress

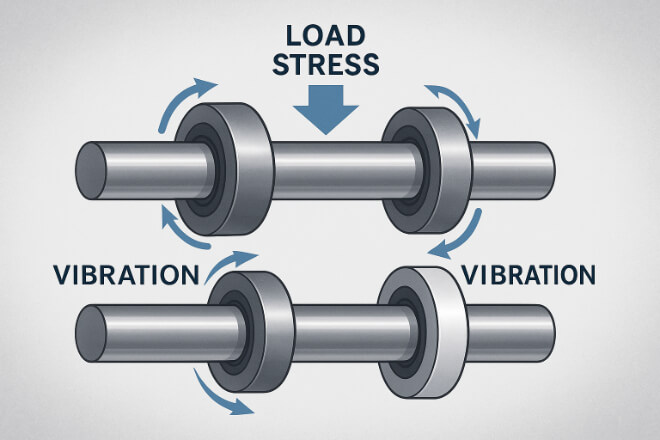

When bushings are used in high-speed rotating systems, they experience constant radial and axial loads.

Tungsten carbide resists deformation thanks to its metal binder phase. Even when subjected to shock loads or vibration, it maintains alignment and dimensional accuracy.

Ceramic bushings, although very hard, can develop microcracks or fracture if the load exceeds a certain limit or if installation is slightly misaligned.

In dynamic environments, carbide outperforms ceramic by offering both hardness and structural stability.

Thermal Stability and Heat Resistance

| Factor | Carburo de tungsteno | Cerámico |

|---|---|---|

| Max Working Temperature | Up to 1000°C | Up to 1200°C |

| Thermal Conductivity (W/m·K) | 80–100 | 20–30 |

| Thermal Shock Resistance | Excelente | Pobre |

Although ceramic can withstand higher temperatures, tungsten carbide manages thermal gradients much better.

When equipment cycles between hot and cold — such as in turbines or pumps — ceramics may crack, while carbide remains dimensionally stable.

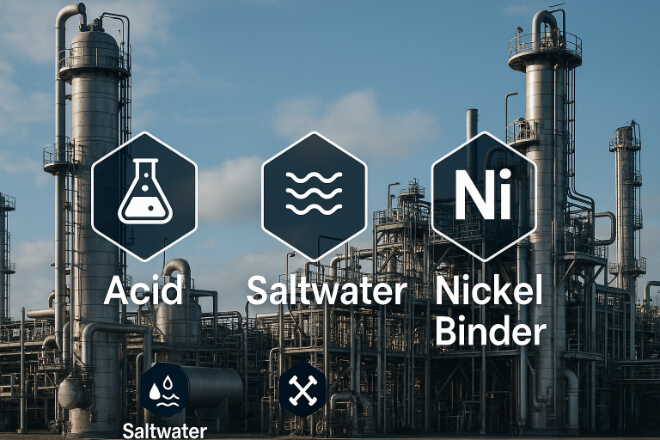

Corrosion Resistance and Chemical Compatibility

In corrosive environments such as seawater or acid-based fluids:

Ceramic bushings perform well since they are chemically inert.

Tungsten carbide, especially nickel-bonded grades, also offers excellent Resistencia a la corrosión and avoids pitting.

The difference lies in mechanical support: while ceramics resist corrosion longer, they lack the toughness to handle sudden pressure spikes or vibration.

For combined mechanical and chemical stress, carbide remains the more balanced option.

Impact and Vibration Resistance

One of the most important differences between the two materials is their response to impact and vibration.

Ceramics perform well in static, clean environments (like precision instruments). But when exposed to repeated vibration or uneven loads, cracks may start at microscopic flaws.

Tungsten carbide, reinforced by a metal matrix, absorbs impact energy without shattering — ideal for pumps, compressors, and downhole tools.

In real-life tests, tungsten carbide bushings survive up to 20× more impact cycles before showing failure compared to ceramics.

Cost and Service Life Comparison

| Factor | Carburo de tungsteno | Cerámico |

|---|---|---|

| Costo inicial | Alto | Moderado |

| Average Service Life | 5–10× longer | Medio |

| Repairability | Difficult but rarely needed | Not repairable (brittle) |

| Total Cost of Ownership | Lower (longer lifespan) | Higher (frequent replacement) |

Though tungsten carbide costs more upfront, its durability and impact resistance make it more economical over the full lifecycle of the equipment.

Aplicaciones ideales

| Solicitud | Preferred Material | Razón |

|---|---|---|

| High-Pressure Pumps | Carburo de tungsteno | Handles stress, vibration, and wear |

| Precision Instruments | Cerámico | High stiffness and smoothness |

| Offshore or Chemical Plants | Tungsten Carbide (Nickel-bonded) | Excellent corrosion and stress tolerance |

| Low-Vibration, Clean Environments | Cerámico | Lightweight and inert |

For stress-intensive or abrasive applications, tungsten carbide remains the best performer.

Ceramics are ideal for precise, low-stress systems where weight and chemical purity are key.

Final Verdict

When it comes to performance under stress, bujes de carburo de tungsteno clearly lead.

Their ability to handle impact, vibration, and combined mechanical loads makes them the best option for most industrial uses.

Ceramic bushings are perfect when the environment is clean, stable, and chemical purity matters more than impact strength.

For continuous, high-load operations, carbide wins in both reliability and lifecycle cost.

Conclusión

Choosing between tungsten carbide and ceramic bushings depends on the working environment and stress level.

If your system runs under pressure, vibration, or abrasive flow, tungsten carbide ensures long service life and minimal downtime.

If your process involves chemical exposure and precision control, ceramics deliver lightweight and clean performance.

For industrial decision-makers, the right choice can improve efficiency, reduce maintenance, and protect critical equipment.

Si desea conocer más detalles sobre alguna empresa, no dude en contactarnos. Contáctanos.