In many industrial machines — from pumps and compressors to drilling tools — bushings are critical parts that support shafts, reduce vibration, and prevent metal-to-metal contact.

For decades, engineers relied on conventional metal bushings such as bronze, stainless steel, or brass. But as machines run faster and face harsher environments, these metals often wear out too quickly.

Aquí es donde bujes de carburo de tungsteno stand out. Their unmatched dureza, resistencia al desgaste, and stability make them the preferred choice for industries that demand long-term performance under extreme stress.

In this article, we’ll explain why choosing tungsten carbide over traditional metal bushings can significantly improve reliability, reduce downtime, and lower long-term maintenance costs.

The Problem with Conventional Metal Bushings

Traditional metal bushings like bronze or steel work well in low-speed and moderate-load conditions. However, they have several limitations:

They wear quickly under abrasive or high-pressure conditions.

They expand or deform at high temperature.

They are prone to corrosion and pitting in aggressive fluids.

Frequent replacements lead to increased downtime and cost.

As machinery becomes more compact and powerful, these materials often fail to keep up with modern operating conditions.

What Makes Tungsten Carbide Different

Tungsten carbide (WC) is a metal-ceramic composite, made by sintering tungsten and carbon powders at very high temperature.

The result is an ultra-hard, extremely dense material that combines:

Dureza cerca del diamante

Alta resistencia a la compresión

Excelente Resistencia a la corrosión

Muy baja fricción

Because of these characteristics, tungsten carbide bushings provide a much longer service life and superior dimensional stability compared to any traditional metal bushing.

Comparison between the two

| Characteristic | Carburo de tungsteno | Conventional Metal (Bronze/Steel) |

|---|---|---|

| Dureza (HRA) | 88–92 | 35–45 |

| Resistencia a la compresión (MPa) | 4000+ | 500–900 |

| Resistencia al desgaste | Excelente | Moderado |

| Thermal Expansion | Muy bajo | Alto |

| Resistencia a la corrosión | Excellent (especially Nickel-bonded) | Limited (especially in seawater/acids) |

From this comparison, it’s clear that bujes de carburo de tungsteno outperform conventional metals in nearly every mechanical category.

Performance Under Pressure and Speed

When exposed to high rotational speed or pressure, conventional metals can deform or seize due to friction heat.

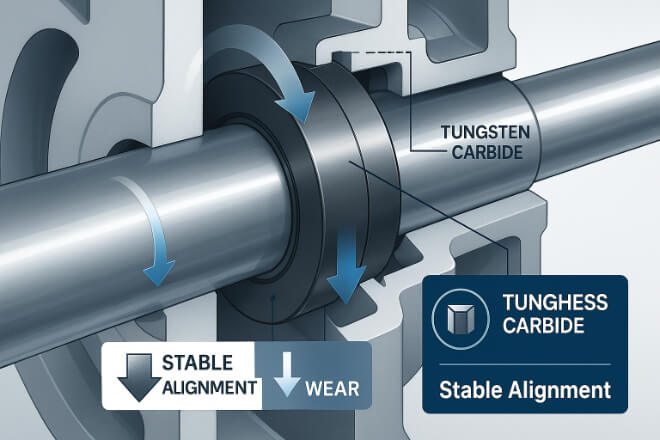

Tungsten carbide’s low thermal expansion and high hardness make it extremely stable even under high-load, high-speed conditions. This allows precise shaft alignment and consistent performance in:

Submersible pumps

Turbo compressors

Drilling tools

Hydraulic cylinders

Its resistance to plastic deformation under stress ensures longer wear life and reduced vibration — key for equipment that must run continuously.

Resistance to Wear and Erosion

In abrasive environments like slurry, sand, or chemical particles, bronze or steel bushings erode rapidly.

Once the surface wears unevenly, it causes shaft misalignment and seal failure.

Tungsten carbide bushings resist both abrasive and adhesive wear due to their dense microstructure.

Even after long operation, they maintain smoothness and correct geometry — reducing energy loss and preventing premature shaft damage.

Corrosion Resistance and Chemical Stability

| Environment | Carburo de tungsteno | Conventional Metal |

|---|---|---|

| Fresh Water | Excelente | Bien |

| Seawater | Very Good (Nickel-bonded) | Corrodes quickly |

| Acidic Fluids | Stable | Prone to pitting |

| Oil or Chemical Slurry | Excelente | Justo |

Because tungsten carbide is chemically inert, it resists oxidation and pitting even in aggressive chemical or marine conditions — a huge advantage for offshore and chemical processing equipment.

Cost and Long-Term Value

At first glance, tungsten carbide bushings are more expensive than traditional metal types.

However, their total cost of ownership is far lower when you consider service life, maintenance, and downtime reduction.

| Factor | Carburo de tungsteno | Conventional Metal |

|---|---|---|

| Costo inicial | Alto | Bajo |

| Frecuencia de reemplazo | Bajo | Alto |

| Vida útil | 5–10× Longer | Corto |

| Total Cost of Ownership | Más bajo | Más alto |

Most companies recover the higher upfront cost within one to two years through fewer replacements, lower maintenance, and better uptime.

Applications Where Tungsten Carbide Excels

Tungsten carbide bushings are ideal in environments that involve pressure, vibration, abrasion, or corrosive fluids. Typical industries include:

Petróleo y gas: Downhole tools, mud pumps, compressors

Chemical Processing: Mixers, reactors, acid pumps

Power Generation: Boiler feed pumps, turbines

Marine and Offshore: Seawater and cooling pumps

Minería and Drilling: Slurry and grit-handling systems

Each of these settings exposes bushings to heavy wear — conditions where conventional metals often fail prematurely.

Environmental and Operational Benefits

Tungsten carbide bushings also support sustainability goals by reducing material waste and downtime.

Fewer replacements mean less scrap metal and waste.

Energy efficiency improves due to reduced friction.

Lower maintenance reduces lubricant use and machine idling time.

This not only extends the machine’s life but also contributes to safer, more environmentally friendly industrial operations.

Final Verdict

For decision-makers evaluating material options, the evidence is clear:

Tungsten carbide bushings outperform conventional metal bushings in durability, resistencia al desgaste, and lifetime value.

They’re not just stronger — they’re smarter investments for high-performance, high-reliability machinery.

While metals remain useful for low-stress systems, tungsten carbide offers the best combination of strength, precision, and long-term cost savings for modern industrial equipment.

Conclusión

Upgrading from conventional metal bushings to tungsten carbide is not just a material change — it’s an operational upgrade.

By choosing tungsten carbide, companies gain:

Longer component life

Tiempo de inactividad reducido

Costos de mantenimiento más bajos

Better machine performance

In short, tungsten carbide bushings turn maintenance budgets into performance investments.

Si desea conocer más detalles sobre alguna empresa, no dude en contactarnos. Contáctanos.