Tungsten carbide bushings are widely used in industries requiring high resistencia al desgaste, durability, and tenacidad.

The performance and longevity of these bushings depend heavily on their composition, particularly the binder percentage.

The binder, typically cobalt or nickel, plays a crucial role in the mechanical properties and performance of the bushing.

In this blog, we will explore how different binder percentages affect the properties of tungsten carbide bushings, and how manufacturers can optimize the binder content to meet specific operational requirements.

What is the Binder in Tungsten Carbide Bushings?

En bujes de carburo de tungsteno, tungsten carbide particles are held together by a binder material, which is typically cobalt (Co) or nickel (Ni).

The binder’s primary function is to provide tenacidad and help bind the hard tungsten carbide particles together.

While tungsten carbide itself is extremely hard and resistente al desgaste, it is also brittle.

The binder material provides some flexibility and shock resistance, improving the overall performance of the bushing.

Cobalt Binder: Cobalt is the most commonly used binder for tungsten carbide. It helps to improve the wear resistance and toughness of the bushing.

Nickel Binder: Nickel-bonded tungsten carbide is used when there are higher corrosion or temperature resistance requirements, as nickel offers better resistance to heat and corrosion than cobalt.

How the Binder Percentage Affects Tungsten Carbide Bushings

The binder percentage in bujes de carburo de tungsteno can vary, typically ranging from 6% to 25% by weight. The percentage of binder has a significant impact on the following properties:

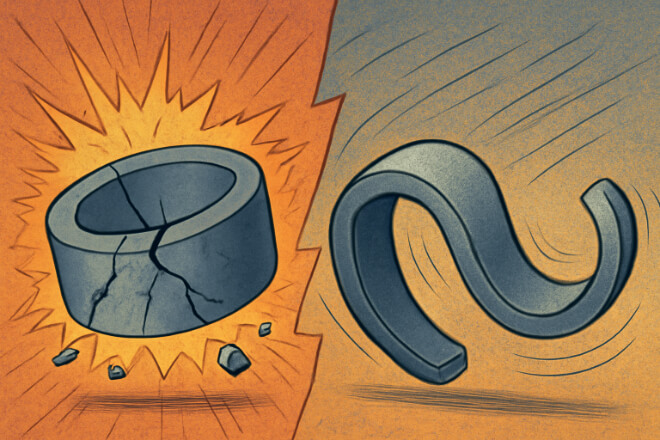

1). Dureza

Lower Binder Percentage (6-10%):

Tungsten carbide with a lower binder content tends to have higher hardness.

This is because there is more tungsten carbide in the mix, making the material harder and more wear-resistant.

However, the lower the binder content, the more brittle the material becomes, making it susceptible to cracking under shock or high impact.

Higher Binder Percentage (15-25%):

Increasing the binder percentage makes the material more ductile and tough. However, this comes at the expense of hardness.

A higher binder content means there is less tungsten carbide, so the material will be softer and may wear more quickly under high-friction conditions.

2). Tenacidad

Low Binder Content:

Tungsten carbide with low binder content is harder but more brittle, meaning it is prone to cracking under impact or high-stress conditions.

High Binder Content:

A higher binder percentage increases the toughness of the material, making it more resistant to cracking and chipping.

This is particularly important in applications where the bushings are exposed to shock loads or vibrations.

Higher Tungsten Carbide Content:

A higher percentage of tungsten carbide (with a lower binder content) leads to better wear resistance, as tungsten carbide is one of the hardest materials available.

More Binder:

While a higher binder percentage improves toughness, it may reduce wear resistance since the binder itself is softer compared to tungsten carbide.

Therefore, a balance between wear resistance and toughness must be achieved depending on the application.

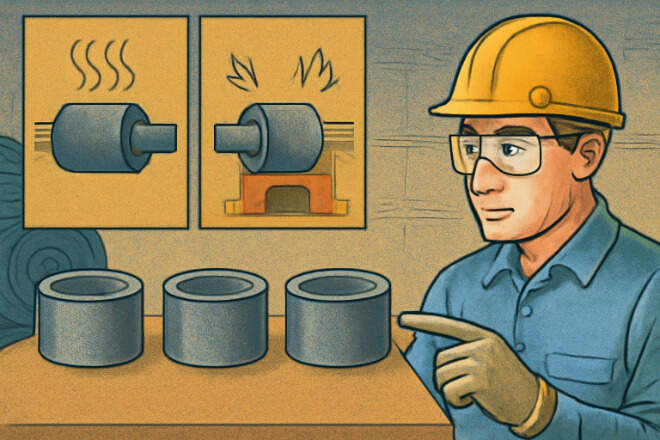

Factors to Consider When Choosing the Binder Percentage

When selecting the binder percentage for tungsten carbide bushings, several factors must be considered:

1). Application Requirements

High-Impact Applications:

If the bushings will be subjected to high-impact or shock loading, a higher binder percentage is usually preferred. This helps prevent cracking and provides better resilience.

High-Wear Applications:

In applications where wear resistance is the primary concern, a lower binder percentage is often the better choice.

This increases the hardness and resistencia al desgaste of the bushing, making it ideal for high-friction environments.

2). Environmental Conditions

In environments where the bushing will be exposed to corrosive substances or high temperatures, nickel is preferred as the binder.

A higher binder percentage may also be beneficial in these cases to improve toughness and overall resistance.

Resistencia a la temperatura:

For high-temperature applications, using nickel as a binder with a higher binder percentage can improve the thermal stability of the bushing.

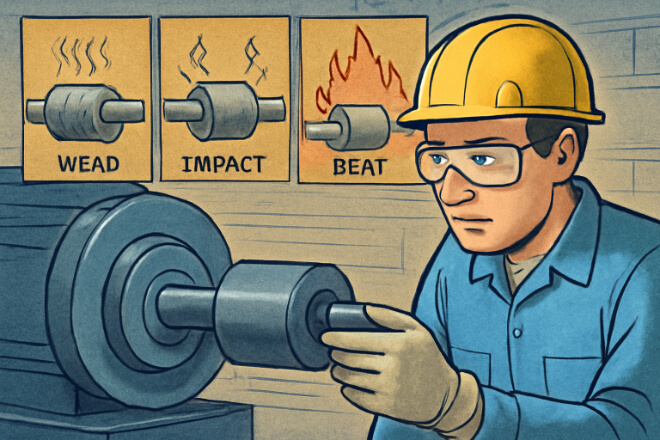

3). Manufacturing Considerations

Costo:

Tungsten carbide with a higher binder percentage is generally less expensive because cobalt or nickel binders are typically cheaper than tungsten carbide itself.

However, using more binder can sacrifice some of the bushing’s hardness and wear resistance.

Maquinabilidad:

Bushings with higher binder content tend to be easier to machine, while those with lower binder content may require more advanced manufacturing processes due to their hardness.

4). Binder Percentage vs. Properties of Tungsten Carbide Bushings

| Binder Percentage | Dureza (HRA) | Tenacidad | Resistencia al desgaste |

|---|---|---|---|

| 6-10% | Alto | Bajo | Muy alto |

| 10-15% | Moderado | Moderado | Alto |

| 15-25% | Bajo | Alto | Moderado |

How to Choose the Right Binder Percentage for Your Application

To select the appropriate binder percentage, it’s essential to assess the specific requirements of your application. Consider the following:

For High Resistencia al desgaste:

If your application demands maximum wear resistance, you may want to use a bushing with a lower binder percentage (6-10%). This will provide superior hardness and better performance in high-friction environments.

For High Impact or Shock Load:

If your application involves heavy impact or shock loading, a bushing with a higher binder percentage (15-25%) will provide the necessary toughness to resist cracking and improve resilience.

For High-Temperature or Corrosive Environments:

If the bushing will operate in high-temperature or corrosive conditions, consider using a nickel binder with a slightly higher binder percentage to improve both thermal stability and resistance to corrosion.

Conclusión

The binder percentage in tungsten carbide bushings significantly influences their performance in various industrial applications.

By adjusting the binder content, manufacturers can balance between hardness, wear resistance, and toughness to meet specific operational needs.

Whether you need a bushing for high-wear, high-impact, or high-temperature environments, understanding the effects of binder percentage will help you optimize the performance and longevity of your tungsten carbide bushings.

Si desea conocer más detalles sobre alguna empresa, no dude en contactarnos. Contáctanos.