Surface roughness plays a crucial role in the performance and lifespan of bushings, particularly in demanding industrial applications.

Tungsten carbide bushings, known for their exceptional resistencia al desgaste y dureza, require specific surface roughness values to ensure optimal functioning over time.

In this blog, we will discuss how surface roughness affects the lifespan of bushings, the ideal values for different applications, and how to optimize surface finishing techniques for long-lasting performance.

What is Surface Roughness?

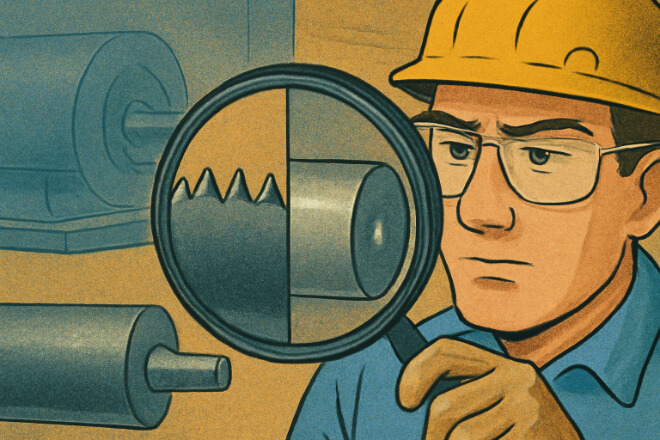

Surface roughness refers to the small, closely spaced deviations on a material’s surface, which are typically measured in terms of height and spacing.

These irregularities can be caused by various factors during the manufacturing process, such as machining or grinding.

The roughness of a surface affects how two components interact, especially in sliding applications where one part moves against another.

Surface roughness is commonly measured in micrometers (µm) or microinches (µin).

The key parameter used to measure surface roughness is Ra (Arithmetic Average Roughness), which represents the average height of the peaks and valleys on the surface.

Low Surface Roughness (Smooth): A low Ra value means a smoother surface, which reduces friction and wear.

High Surface Roughness (Rough): A higher Ra value indicates more surface irregularities, leading to increased friction and wear.

How Does Surface Roughness Affect the Lifespan of Bushings?

The surface roughness of the bushing directly impacts several critical factors that determine its lifespan, including:

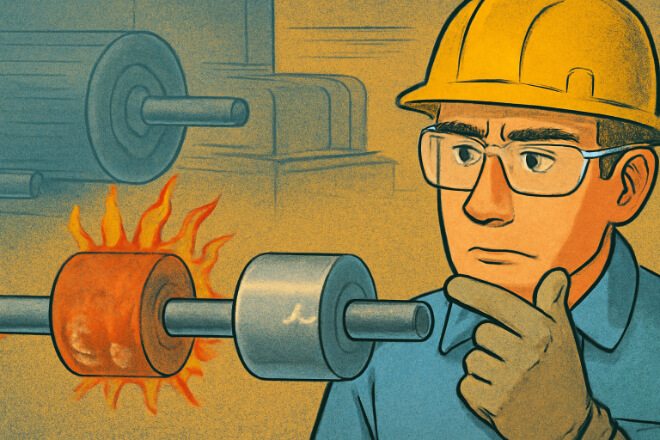

1). Friction and Wear

A smoother surface (lower Ra value) reduces friction between the bushing and the mating surface, such as a shaft.

Lower friction leads to less wear, which extends the lifespan of both the bushing and the shaft.

Conversely, a rougher surface increases friction, causing more heat and wear, which shortens the lifespan of both components.

Low Surface Roughness: Reduces friction, minimizes heat buildup, and lowers wear rates.

High Surface Roughness: Increases friction, generates more heat, and accelerates wear.

2). Lubrication Efficiency

The surface roughness of the bushing also affects the efficiency of lubrication.

A smoother surface allows the lubricant to form a more consistent and effective film between the bushing and the shaft.

This film helps to reduce friction and prevent direct contact between the surfaces, further reducing wear.

In contrast, a rough surface can break down the lubricant film, leading to increased friction and wear.

3). Contact Area and Load Distribution

A rougher surface increases the contact area between the bushing and the mating component, which can result in higher localized pressure points.

This can lead to faster material degradation, while a smoother surface ensures more even load distribution and less wear over time.

Ideal Surface Roughness Values for Tungsten Carbide Bushings

The ideal surface roughness values for bujes de carburo de tungsteno depend on the application and the materials involved. Below are general guidelines for surface roughness values:

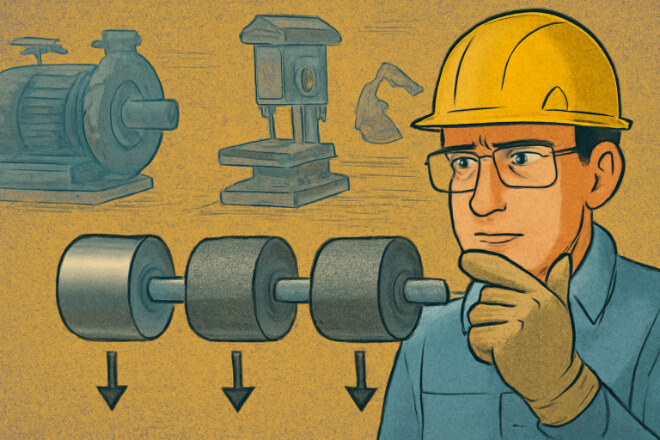

1). High-Speed Applications

In high-speed applications, such as pumps or precision machinery, lower surface roughness is typically required to reduce friction and heat generation.

A smoother surface helps maintain the integrity of the bushing and reduces the chances of premature wear.

Ideal Ra Value: 0.1–0.3 µm (polished or ground surfaces)

Application Examples: High-speed pumps, precision motors, CNC machines.

2). Moderate-Speed, Moderate-Load Applications

For moderate-speed applications with moderate loads, such as automotive parts or industrial machinery.

A slightly higher surface roughness may be acceptable while still providing a good balance of resistencia al desgaste and performance.

Ideal Ra Value: 0.3–0.5 µm (ground or lightly polished surfaces)

Application Examples: Gearboxes, conveyor systems, machine tools.

3). High-Load, Low-Speed Applications

In high-load, low-speed applications, such as mining equipment or heavy-duty machinery, higher surface roughness may be acceptable to handle the increased stresses.

However, it’s still crucial to maintain a balance to avoid excessive wear.

Ideal Ra Value: 0.5–1.0 µm (ground or unpolished surfaces)

Application Examples: Heavy machinery, mining equipment, high-load bearings.

Surface Roughness Values for Different Applications

| Application Type | Ideal Ra Value | Acabado de la superficie |

|---|---|---|

| High-Speed Applications | 0.1–0.3 µm | Polished or Ground |

| Moderate-Speed, Moderate-Load | 0.3–0.5 µm | Ground or Lightly Polished |

| High-Load, Low-Speed | 0.5–1.0 µm | Ground or Unpolished |

How to Achieve the Ideal Surface Roughness

Achieving the ideal surface roughness for tungsten carbide bushings involves choosing the right manufacturing processes and techniques. Some common methods include:

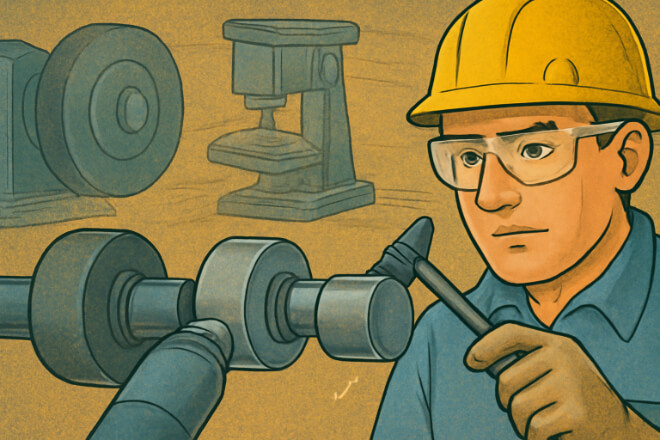

1). Grinding

Grinding is a common method for achieving low surface roughness. By using grinding wheels with fine abrasives, manufacturers can achieve a smooth surface finish.

This method is particularly effective for high-speed and moderate-speed applications.

2). Polishing

Polishing is used to create ultra-smooth surfaces with very low roughness values (Ra < 0.1 µm). This is ideal for applications requiring minimal friction and wear, such as in precision pumps and motors.

3). Lapping

Lapping is a precise finishing process used to achieve a very smooth surface with minimal roughness.

It involves rubbing the bushing against a flat surface with fine abrasives and is often used for high-precision applications.

4). Surface Coatings

In some cases, applying coatings such as diamond-like carbon (DLC) or other low-friction coatings can help reduce surface roughness and improve resistencia al desgaste, especially for high-load applications.

Maintenance and Monitoring

To ensure that the bushing continues to perform optimally, it’s essential to regularly monitor its surface roughness and overall condition.

Regular maintenance, lubrication, and inspection can help identify any surface wear or changes that could negatively affect performance.

Conclusión

Surface roughness is a key factor in determining the lifespan and performance of tungsten carbide bushings.

By selecting the right surface finish based on the specific application and load conditions, manufacturers can significantly extend the lifespan of their bushings, reduce wear, and enhance operational efficiency.

Whether through grinding, polishing, or lapping, achieving the optimal surface roughness ensures that the bushing performs well even in demanding environments.

Si desea conocer más detalles sobre alguna empresa, no dude en contactarnos. Contáctanos.