Tungsten carbide bushings Son conocidos por su fuerza, dureza, and long service life. They are widely used in pumps, compressors, turbines, and other rotating equipment.

But in real industrial environments, some bushings fail much earlier than expected. Early failure means unplanned downtime, higher maintenance costs, and possible damage to shafts or seals.

This article explains the main reasons behind premature failure and what decision-makers can do to prevent it.

Poor Raw Material Quality

Not all tungsten carbide bushings are produced with the same material quality. Poor powder quality or incorrect binder ratios can significantly reduce strength and resistencia al desgaste.

1). Common Raw Material Problems

Low-purity polvo de carburo de tungsteno

Incorrect cobalt or nickel binder percentage

Mixed grain sizes leading to weak microstructure

Contaminants such as oxygen or carbon imbalance

2). How This Leads to Early Failure

Weak bonding → chipping and breakage

Fast wear even under normal load

3). Typical Quality Checks

| Defect | Cause | Impact on Bushing | Risk Level |

|---|---|---|---|

| Low-purity powder | Poor powder refining | Weak microstructure, porosity | Alto |

| Wrong binder ratio | Inaccurate mixing | Low toughness or low hardness | Alto |

| Contamination | Dust, oxygen exposure | Cracks after sintering | Medio |

Material defects are often invisible to the naked eye but directly impact long-term durability.

Incorrect Sintering or Manufacturing Defects

Even if the raw material is high quality, manufacturing problems can still lead to weak bushings.

1). Common Manufacturing Defects

Uneven densidad during pressing

Poor sintering temperature control

Shrinkage issues

Voids caused by gas release

Internal cracks

These defects reduce structural strength, making the bushing fail when exposed to stress or vibration.

2). Why Sintering Matters

Tungsten carbide must be sintered at extremely high temperatures.

If parameters are not controlled:

Carbide grains may grow too large

Binder may separate

Porosidad increases

Dureza varies across the part

3). Signs of Manufacturing Failure

Sudden cracking during installation

Chips around the chamfer area

Random breakage under normal load

Uneven wear pattern inside the bore

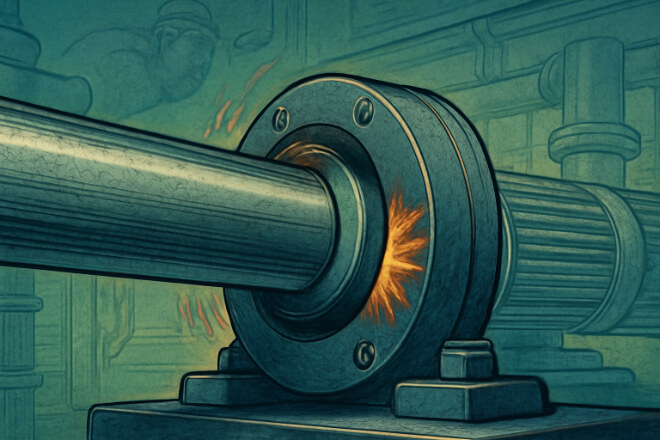

Misalignment Between Shaft and Bushing

One of the fastest ways to destroy a tungsten carbide bushing is misalignment. Even a small angle or offset between shaft and bushing creates extreme stress.

1). Causes of Misalignment

Poor pump or motor alignment

Bent shaft

Loose baseplate

Incorrect installation of bearings or seals

Thermal expansion differences

2). Effects on the Bushing

One-sided wear

Heavy friction on one area

Cracking along the inner wall

Vibration leading to fatigue

3). Typical Alignment Errors

| Misalignment Type | Cause | Bushing Damage | Risk Level |

|---|---|---|---|

| Angular misalignment | Motor/pump coupling error | One-side contact, heavy wear | Alto |

| Offset misalignment | Shifted shaft or housing | Inner wall cracking | Alto |

| Thermal misalignment | Expansion under high temperature | Surface scoring | Medio |

Misalignment is a preventable failure mode but often overlooked.

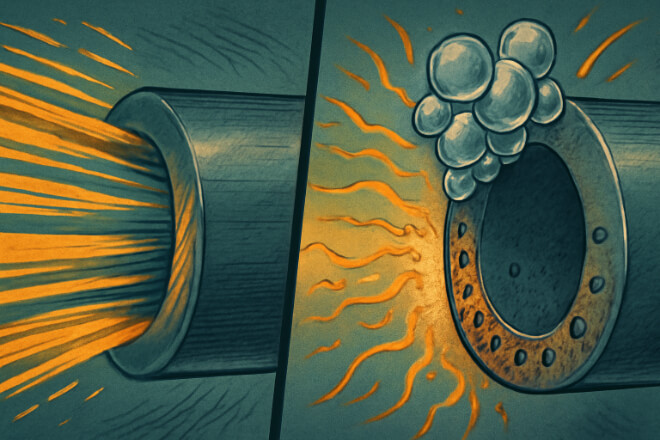

Cavitation and Erosion Damage

Tungsten carbide is hard, but cavitation and erosion can still wear it down quickly under the wrong conditions.

1). Cavitation

Low-pressure areas produce vapor bubbles. When these bubbles collapse, they hit the bushing surface with high energy, causing:

Pitting

Localized crater-like marks

Fast removal of material

2). Erosion

High-velocity fluids or particles (sand, rust, debris) strike the bushing surface repeatedly. This leads to:

Grooves

Smooth directional wear

Loss of thickness over time

3). Where This Happens Most Often

Pump inlets

High-flow areas

Pumps handling dirty or abrasive fluids

Chemical pumps operating at low NPSH

Rapid erosion or cavitation can destroy a bushing even when alignment and material quality are perfect.

Poor Lubrication or Dry Running

Tungsten carbide bushings depend on proper fluid lubrication.

If lubrication is poor or missing, the bushing will fail quickly due to heat and friction.

1). Common Lubrication Problems

Start-up without enough liquid

Blocked or restricted lubrication passages

Air pockets in the pump

Wrong type of process fluid

Low flow rate in vertical pumps

2). Effects of Poor Lubrication

Calentamiento excesivo

Surface scoring

Sudden cracking

Binding between bushing and shaft

Even the best carbide grade cannot survive dry running for long.

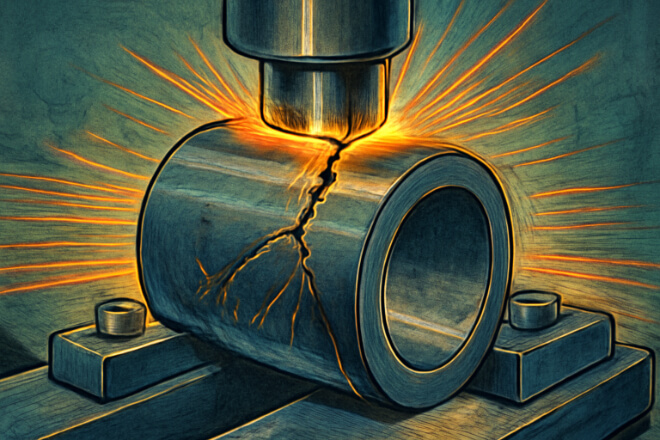

Incorrect Installation Practices

Incorrect installation is one of the most common reasons bushings fail early.

1). Typical Installation Errors

Using excessive force during press-fit

Hammering instead of using a press machine

Not checking the interference fit

Installing at an angle

Ignoring thermal expansion differences

2). Results of Wrong Installation

Cracked bushing during mounting

Chips around edges

Internal stress that causes failure later

A proper installation process is often the difference between a long-lasting bushing and one that fails within weeks.

Operating Conditions Outside Design Limits

Some pumps operate far beyond their original design limits.

1). Examples

Higher speed or pressure than expected

Unexpected dry solids in the fluid

Extreme operating temperatures

Strong chemical corrosion

Repeated start-stop cycles

2). How This Affects Bushings

Accelerated wear

Binder leaching

Thermal cracking

Structural fatigue

Using the wrong carbide grade for a specific chemical or temperature environment is a major cause of early failure.

Conclusión

Most premature tungsten carbide bushing failures come from a combination of material problems, misalignment, cavitation, installation mistakes, or harsh operating conditions.

By understanding these causes, decision-makers can prevent early failure, extend equipment life, and reduce downtime in pumps and other rotating systems.

Si desea conocer más detalles sobre alguna empresa, no dude en contactarnos. Contáctanos.