When designing systems that use bujes de carburo de tungsteno, understanding the behavior of materials under stress is essential for ensuring their durability and performance.

Hoop stress and press-fit calculations are two critical factors in the design process.

Hoop stress refers to the stress experienced by a material under pressure, while press-fit calculations help determine the interference between a bushing and its housing.

In this article, we will discuss how to calculate and consider these two factors to ensure the optimal performance of tungsten carbide bushings in demanding applications.

What Is Hoop Stress?

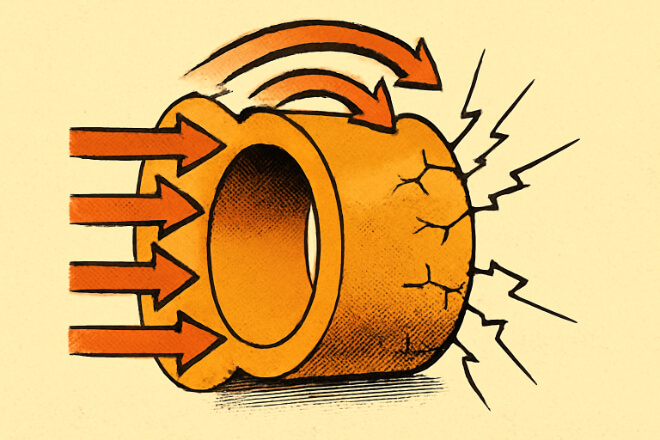

Hoop stress, also known as circumferential stress, is the stress that acts tangentially to a cylindrical object when it is subjected to internal or external pressure.

For tungsten carbide bushings, hoop stress occurs when the bushing is subjected to internal pressures from the shaft or external pressures from the surrounding housing.

1). Why Hoop Stress Matters:

Material strength: Understanding hoop stress is critical because it directly influences how much pressure the bushing can withstand without cracking or failing. Tungsten carbide is a strong material, but excessive hoop stress can cause it to fracture.

Dimensional stability: Excessive hoop stress can lead to dimensional changes in the bushing, which may affect the fit with the shaft or housing, causing misalignment and premature wear.

Long-term durability: By calculating hoop stress, engineers can ensure that the bushing can handle operational pressures and maintain its integrity over time.

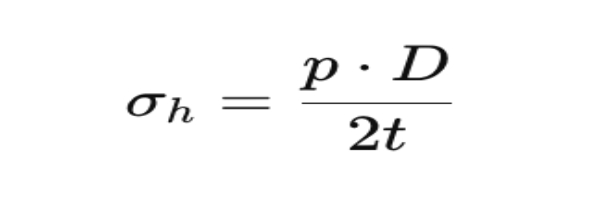

2). Formula for Hoop Stress:

The formula for hoop stress in a thin-walled cylinder is:

Where:

σh = Hoop stress

p= Internal or external pressure

D = Diameter of the cylinder (bushing)

t = Wall thickness of the cylinder

By using this formula, engineers can calculate the hoop stress and determine whether the tungsten carbide bushing can handle the pressure applied during operation.

What Are Press-Fit Calculations?

Press-fit refers to the method of fitting a bushing into a housing or a shaft by using interference.

This interference creates a tight fit between the two components, which helps secure the bushing in place during operation.

Press-fit calculations are crucial to ensure that the interference between the bushing and housing does not cause excessive stress or deformation.

1). Why Press-Fit Calculations Matter:

Secure fit: A proper press-fit ensures that the bushing remains in place during operation, preventing misalignment and reducing wear.

Avoiding damage: If the interference is too high, it can cause excessive hoop stress, which could lead to cracks or fractures in the bushing. Conversely, if the interference is too low, the bushing may loosen, leading to instability.

Optimizing performance: Calculating the optimal press-fit interference helps balance the forces between the bushing and housing, ensuring long-lasting and efficient performance.

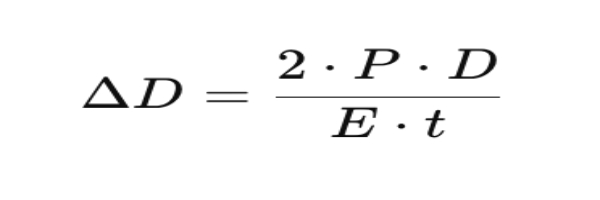

2). Formula for Press-Fit Calculation:

The press-fit calculation can be expressed as:

Where:

ΔD = Change in diameter (interference)

P = Pressure applied to the bushing

D = Diameter of the bushing

E = Modulus of elasticity (for both bushing and housing)

t = Wall thickness of the bushing

This formula helps engineers determine the optimal interference between the bushing and its housing to ensure a secure fit without causing excessive stress.

How Hoop Stress and Press-Fit Work Together

Both hoop stress and press-fit play significant roles in the performance of bujes de carburo de tungsteno.

The key is to ensure that the bushing can withstand the operational pressures while maintaining a secure fit within the housing or shaft.

Interactions Between Hoop Stress and Press-Fit:

Hoop stress during press-fit:

The process of press-fitting the bushing into the housing generates hoop stress, as the bushing experiences both internal and external pressures.

If the press-fit is too tight, it can cause excessive hoop stress, leading to cracking or deformation.

Pressure balance:

Proper press-fit calculations ensure that the interference between the bushing and housing is optimal, preventing excessive hoop stress while securing the bushing in place.

Material limits:

Tungsten carbide is known for its dureza y resistencia al desgaste, but it is also relatively brittle.

Therefore, excessive hoop stress from an overly tight press-fit can lead to failure. Balancing these two factors is essential for ensuring the longevity and performance of the bushing.

Aplicaciones y consideraciones prácticas

Understanding and calculating hoop stress and press-fit values is essential for designing tungsten carbide bushings that can handle high-pressure and high-performance applications.

Below are some examples of applications where these calculations are crucial:

1). Key Applications:

Pump systems: In slurry pumps and chemical pumps, the bushing must withstand high internal pressures and a tight press-fit to maintain stability and reduce wear.

Bearings and shafts: Tungsten carbide bushings used in bearings must have the correct press-fit to prevent misalignment, which could lead to increased wear and failure.

High-speed machinery: In high-speed systems, proper press-fit and hoop stress calculations are critical to ensuring smooth operation and preventing catastrophic failure.

2). Factors to Consider:

Operating conditions: The pressures, temperatures, and vibrations experienced by the bushing will influence the optimal press-fit and hoop stress calculations.

Bushing material properties: The properties of tungsten carbide, including its hardness and brittleness, must be considered when calculating press-fit interference and hoop stress.

Tolerance limits: Manufacturing tolerances must be carefully controlled to ensure that the bushing and housing fit together properly and that the calculated hoop stress and press-fit values are achieved.

Conclusión

Proper hoop stress and press-fit calculations are essential for ensuring that tungsten carbide bushings perform reliably and efficiently under pressure.

By accurately calculating the hoop stress and determining the appropriate press-fit interference, engineers can ensure that the bushing fits securely within the housing while withstanding operational pressures.

This balance ensures optimal performance, extended lifespan, and reduced maintenance costs for industrial systems that rely on tungsten carbide bushings.

Si desea conocer más detalles sobre alguna empresa, no dude en contactarnos. Contáctanos.