Tungsten carbide bushings son conocidos por su excepcional resistencia al desgaste, durezay durabilidad.

However, achieving a mirror-finish on the surface of these bushings is crucial for certain high-performance applications, where minimal friction, enhanced wear resistance, and smooth operation are required.

The process of lapping and polishing is essential in achieving this mirror-finish. In this article, we will explore the steps involved in lapping and polishing tungsten carbide bushings to achieve.

Amirror-like surface, the tools and techniques required, and why this finish is important for the performance of the bushings.

What is Lapping and Polishing?

Lapping and polishing are two critical finishing processes used to achieve an ultra-smooth surface on materials like tungsten carbide.

1). Lapping:

Lapping is a precision process that uses a lapping compound and a lapping plate to remove small amounts of material from the surface of the tungsten carbide bushing. It is used to achieve a highly uniform, flat surface.

During lapping, fine abrasives are applied to the surface, which gradually smoothens it by removing imperfections and unevenness.

2). Polishing:

Polishing is the final step after lapping. It uses a polishing compound and a soft cloth or polishing wheel to create an even smoother surface. Polishing reduces the roughness of the material further, resulting in a high-gloss, mirror-like finish.

The polishing process involves finer abrasives that are less aggressive than those used in lapping, giving the bushing a reflective surface.

Importance of Mirror-Finish for Tungsten Carbide Bushings

Achieving a mirror-finish on tungsten carbide bushings is important for several reasons:

Benefits of Mirror-Finish Tungsten Carbide Bushings:

Reduced Friction: A smooth, mirror-like surface reduces friction between the bushing and the shaft, leading to lower wear rates and better energy efficiency.

Mejorado Resistencia al desgaste: A smoother surface reduces the likelihood of material degradation due to abrasion or galling.

Enhanced Resistencia a la corrosión: A polished surface is less likely to collect dirt, dust, or contaminants that could lead to corrosion.

Longer Lifespan: By minimizing wear and reducing friction, mirror-finish tungsten carbide bushings last longer, offering better value in the long run.

Lapping Process for Tungsten Carbide Bushings

The lapping process involves using a lapping plate and abrasive materials to gradually remove material from the surface of the tungsten carbide bushing.

Here’s a step-by-step guide to the process:

Lapping Steps:

Prepare the Lapping Plate:

The plate is typically made of cast iron or steel. It should be clean and flat before starting.

Choose the Right Abrasive:

Select an appropriate abrasive grit for tungsten carbide. Common abrasives for lapping tungsten carbide include diamond abrasives or aluminum oxide.

Apply Lapping Compound:

A small amount of the abrasive compound is applied to the lapping plate. This helps to create an even, controlled abrasive action during the process.

Begin the Lapping Motion:

The bushing is then placed onto the lapping plate, and a figure-eight motion is used to evenly distribute the abrasive compound over the surface of the bushing. This motion ensures that the material is removed uniformly.

Check the Surface Regularly:

Throughout the process, check the surface of the bushing to ensure that the desired smoothness is achieved. The bushing is periodically cleaned to remove accumulated debris.

Finish Lapping:

Continue lapping until the desired smoothness is achieved, which typically results in a Ra (roughness average) value of 0.2 µm or lower.

Polishing Process for Tungsten Carbide Bushings

After the lapping process, polishing is used to refine the surface and create the mirror finish. Here’s how the polishing process works:

Polishing Steps:

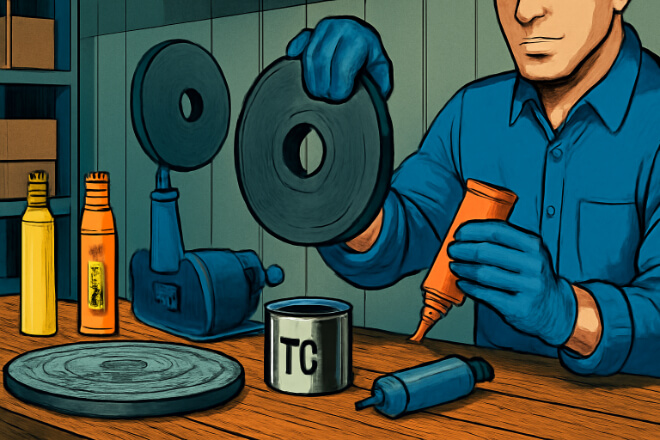

Choose the Right Polishing Compound:

For tungsten carbide, diamond paste is often used as a polishing compound. The paste should be chosen based on the required surface finish.

Select the Polishing Tool:

A polishing wheel or a soft cloth is used to apply the polishing compound to the tungsten carbide bushing.

The polishing tool should be soft to avoid scratching the surface.

Apply Polishing Compound:

The polishing compound is applied to the polishing tool. For finer finishes, start with a coarser grit and move to a finer compound in stages.

Polish the Bushing:

The bushing is gently moved against the polishing wheel or cloth, ensuring even coverage. The polishing motion should be slow and steady to prevent surface damage.

Check the Finish:

Throughout the process, periodically inspect the surface of the bushing for a glossy, mirror-like finish.

Final Polishing:

After achieving the desired finish, a final polish with the finest abrasive paste is used to achieve the mirror finish.

Equipment and Tools Required for Lapping and Polishing

Achieving a high-quality mirror finish on tungsten carbide bushings requires the right tools and equipment.

Below are the key tools and equipment used in the lapping and polishing processes:

Essential Tools and Equipment:

Lapping Plate:

Made from materials like cast iron or steel, the lapping plate is used to evenly distribute abrasives across the bushing surface.

Abrasives:

Diamond abrasives or aluminum oxide abrasives are commonly used for tungsten carbide, depending on the desired finish.

Polishing Wheel/Cloth:

Soft materials like cloth or felt are used for polishing to avoid damaging the surface.

Polishing Paste:

Diamond paste of varying grits is used for polishing the bushing to a mirror-like finish.

Precision Measuring Tools:

To measure the surface roughness (Ra value), precision instruments like a profilometer or surface roughness tester are necessary.

Troubleshooting Common Issues in Lapping and Polishing

While lapping and polishing tungsten carbide bushings, certain issues may arise. Here are some common challenges and solutions:

Common Issues and Solutions:

Uneven Surface Finish: If the surface is uneven after lapping, it may be due to improper motion or an uneven lapping plate. Ensure even pressure and motion during lapping.

Scratches from Polishing: If scratches appear during polishing, the polishing compound may be too coarse, or the polishing wheel may be too hard. Switch to a finer compound or softer material.

Inconsistent Finish: Inconsistent finishes can occur if the bushing is not regularly cleaned during the process, leading to abrasive buildup. Clean the bushing and tools regularly to maintain an even finish.

Conclusión

Lapping and polishing are essential processes for achieving a mirror-finish on tungsten carbide bushings, enhancing their wear resistance, performance, and durability.

By following the correct steps, using the right tools, and addressing potential issues during the process, manufacturers can produce bushings with exceptional surface finishes.

A high-quality finish is critical for ensuring that tungsten carbide bushings operate efficiently in demanding applications, reducing wear and extending their lifespan.

Si desea conocer más detalles sobre alguna empresa, no dude en contactarnos. Contáctanos.