When it comes to industrial applications such as cutting, drilling, and machining, choosing the right material for your tools is critical.

Two of the most commonly used materials for tips are tungsten carbide and ceramics. Both have unique advantages, but the decision of which one to use can be complex.

This article will compare tungsten carbide tips and ceramic tips, exploring their strengths, weaknesses, and how to choose the best option for your specific needs.

What Are Tungsten Carbide Tips?

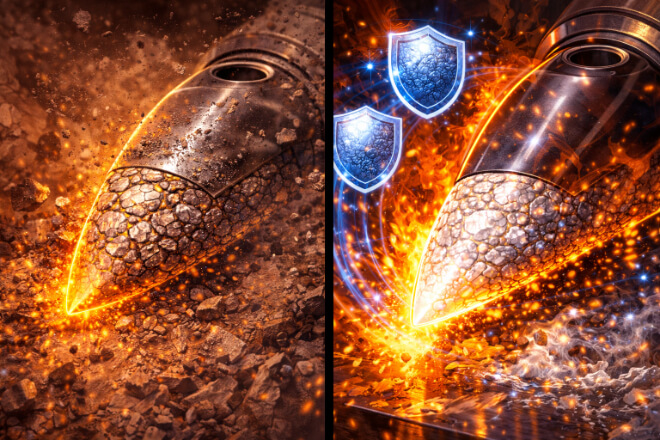

Tungsten carbide is a compound made of tungsten and carbon. It is one of the hardest materials available, often used in tools that need to withstand extreme wear and pressure.

Tungsten carbide tips are known for their toughness, durability, and wear resistance, which makes them suitable for high-stress environments.

1). Key Benefits of Tungsten Carbide Tips:

Alto Hardness: Tungsten carbide is incredibly hard and can withstand intense forces, making it ideal for cutting and drilling tools.

Resistencia al desgaste: It resists abrasion well, which extends tool life in harsh environments.

High Temperature Tolerance: Tungsten carbide can handle high temperatures without losing its strength.

2). Applications of Tungsten Carbide Tips:

Minería and drilling

Metalurgia and machining

Construction equipment

What Are Ceramic Tips?

Ceramics are materials made from inorganic compounds, typically oxides, nitrides, or carbides. Ceramic tips, like tungsten carbide, are used in cutting, grinding, and other high-stress applications.

Ceramic materials offer excellent hardness, but they differ from tungsten carbide in how they behave under pressure and heat.

1). Key Benefits of Ceramic Tips:

Dureza extrema: Ceramics are among the hardest materials, often surpassing even tungsten carbide in terms of hardness.

Resistencia a la corrosión: Ceramic materials are resistant to most acids, chemicals, and corrosion, making them ideal for harsh chemical environments.

Lightweight: Ceramics tend to be lighter than tungsten carbide, which can be advantageous in certain applications.

2). Applications of Ceramic Tips:

Aeroespacial components

Automotor industria

High-precision machining

Key Differences Between Tungsten Carbide and Ceramic Tips

When choosing between tungsten carbide and ceramic tips, it’s important to understand the fundamental differences between the two materials.

Both offer unique benefits, but their performance can vary depending on the application.

1). Durability and Tenacidad

Tungsten carbide is incredibly tough and can handle high impact, making it a great choice for environments where tools face heavy forces.

However, ceramics are more brittle and can crack under high impact, making them less suitable for applications where shock resistance is critical.

Tungsten Carbide: Tough, resistant to cracking, excellent for heavy-duty use.

Ceramics: Extremely hard but can be brittle and crack under high impact.

Tungsten carbide excels in wear resistance, especially when used in abrasive environments.

Ceramic tips, on the other hand, tend to last longer when dealing with high heat and corrosion but may wear down faster in abrasive conditions.

Tungsten Carbide: Best for abrasive wear.

Ceramics: Best for heat and Resistencia a la corrosión.

3). Temperature Tolerance

Tungsten carbide has excellent heat resistance and can operate at higher temperatures without losing its hardness.

Ceramics also offer good temperature resistance but tend to perform better in high-heat, low-wear environments.

Tungsten Carbide: High-temperature tolerance, maintains hardness in extreme conditions.

Ceramics: Excellent for high heat but can fail under extreme mechanical stress.

4). Cost and Availability

Tungsten carbide is generally less expensive than ceramics, though it is still a premium material.

Ceramic materials are often more expensive due to the complexity of their manufacturing processes and their specialized applications.

Tungsten Carbide: More cost-effective for high-demand applications.

Ceramics: More expensive but ideal for specialized, high-performance uses.

How to Choose Between Tungsten Carbide and Ceramic Tips

The choice between tungsten carbide and ceramic tips depends largely on the specific demands of your application. Here are some factors to consider:

1). Application Type

For cutting tools exposed to abrasive materials, tungsten carbide is often the best choice.

For applications in high-temperature or corrosive environments, ceramics may be a better option.

2). Operating Conditions

If your application involves high-impact forces, tungsten carbide’s tenacidad will provide better performance.

If the tool is exposed to chemicals or needs to maintain precision under heat, ceramics may be the better material.

3). Budget Constraints

Tungsten carbide is generally a more budget-friendly option for high-stress, high-wear environments.

Ceramics, while offering excellent performance in specific conditions, can be more expensive due to their manufacturing complexity.

Conclusión

Choosing between tungsten carbide and ceramic tips depends on the specific needs of your operation. Tungsten carbide tips are durable, wear-resistant, and cost-effective, making them ideal for high-stress, abrasive applications.

On the other hand, ceramic tips are perfect for environments where high heat, corrosion, and wear resistance are critical, but they may not be as tough under impact.

By understanding the strengths and weaknesses of each material, decision-makers can choose the best option for their specific needs, ultimately improving efficiency and reducing costs.

Si desea conocer más detalles sobre alguna empresa, no dude en contactarnos. Contáctanos.