Tungsten carbide is a widely used material for industrial cutting tools due to its dureza y resistencia al desgaste.

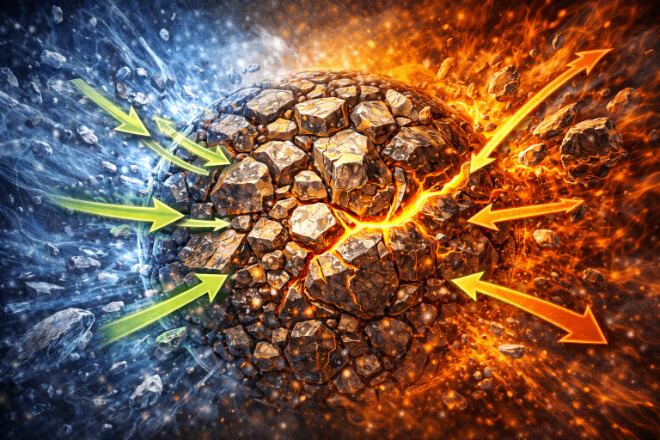

However, even the most durable materials can face challenges in certain conditions. One of the most damaging factors for tungsten carbide tips is thermal shock.

When tungsten carbide tools are exposed to rapid temperature changes, they can suffer from cracking or breakage.

This blog will explore the impact of thermal shock on tungsten carbide tips, what causes it, and how to mitigate its effects in industrial applications.

What is Thermal Shock?

Thermal shock occurs when a material experiences a rapid change in temperature, causing it to expand or contract too quickly.

This sudden stress can lead to cracks or fractures, especially in materials like tungsten carbide, which are hard but brittle.

Unlike other forms of wear or impact, thermal shock is unique because it doesn’t necessarily require physical contact with another object. Instead, it’s the result of drastic temperature changes during the tool’s operation.

In cutting tools, thermal shock can happen when a hot tool is suddenly exposed to a cooler environment, or when it’s used in a high-temperature operation and then cooled too quickly.

This is particularly common in high-speed machining, drilling, or in applications where the tool is subjected to intermittent heating and cooling.

Why is Tungsten Carbide Vulnerable to Thermal Shock?

Tungsten carbide is known for its dureza y resistencia al desgaste, but it is also relatively brittle. This brittleness makes it more susceptible to cracking under sudden changes in temperature.

Tungsten carbide’s crystalline structure, which contributes to its hardness, does not easily absorb the stresses caused by rapid temperature shifts.

The material’s resistance to thermal shock is influenced by several factors, including:

Finer grains offer better tenacidad and resistance to thermal shock, while coarser grains may be more prone to cracking under thermal stress.

Contenido de la carpeta:

The type and amount of binder (usually cobalt) used in tungsten carbide can affect its toughness and impact resistance, which can also influence its ability to handle thermal shock.

Tool design:

The shape and structure of the tool play a role in how it distributes heat and handles thermal stress.

A poorly designed tool with sharp angles or thin sections is more likely to suffer from thermal shock.

How Thermal Shock Affects Tungsten Carbide Tips

The primary effect of thermal shock on tungsten carbide tips is cracking.

When a tungsten carbide tool is subjected to rapid cooling or heating, the differential expansion or contraction can create internal stress.

This stress can lead to microcracks, which grow over time and eventually cause the tool to fail.

Here are some of the specific ways thermal shock affects tungsten carbide tips:

Cracks and fractures: As internal stresses build up, cracks can form in the material. These cracks weaken the tool and make it more susceptible to further damage.

Deformación: In some cases, thermal shock can cause the material to deform, leading to an uneven cutting surface or compromised tool geometry.

Reduced lifespan: Repeated exposure to thermal shock can significantly reduce the tool’s lifespan, leading to frequent replacements and increased operational costs.

Factors that Contribute to Thermal Shock in Tungsten Carbide

Several factors can contribute to the occurrence of thermal shock in tungsten carbide tips. Understanding these factors is key to minimizing the risks in industrial applications:

Rapid Temperature Changes: Sudden cooling or heating, such as when a hot tool is dipped into coolant or exposed to air, is the leading cause of thermal shock.

Tool Operating Temperature: Tools operating at high temperatures are more susceptible to thermal shock, especially when they are rapidly cooled.

Velocidad de corte: High cutting speeds generate heat that can cause the tool to heat up quickly. If the tool cools too quickly, thermal shock can occur.

Cooling Methods: The use of coolants or air cooling systems can rapidly change the temperature of the tool, increasing the likelihood of thermal shock.

Preventing Thermal Shock in Tungsten Carbide Tips

There are several strategies to minimize the risk of thermal shock and protect tungsten carbide tips in industrial applications:

Use of controlled cooling:

Instead of rapid cooling, controlled cooling methods can be employed.

This gradual reduction in temperature helps to reduce the stress on the material and prevents sudden thermal shock.

Proper tool design:

Tools with rounded edges and thicker sections are less prone to thermal shock.

Avoiding sharp angles and thin sections can help distribute heat more evenly and reduce stress concentrations.

Optimized cutting conditions:

Reducing cutting speeds and ensuring proper lubrication can help prevent excessive heat buildup, which is a key contributor to thermal shock.

Material selection:

Using tungsten carbide with a finer grain size and an appropriate binder material can improve toughness and resistance to thermal shock.

Applications Where Thermal Shock is a Concern

Thermal shock is particularly a concern in industries where tools are subjected to high-speed operations and extreme temperatures.

Some common applications where thermal shock may affect tungsten carbide tips include:

Mecanizado de alta velocidad: In machining operations, tools often experience high temperatures due to friction. Rapid cooling during machining or sudden exposure to cooler air can lead to thermal shock.

Perforación: Drilling tools used in high-temperature environments, such as oil drilling or geothermal drilling, are at risk of thermal shock when exposed to rapid changes in temperature.

Cutting and grinding: Tools used for cutting or grinding metal or concrete can become very hot, especially when exposed to friction for extended periods. Rapid cooling can result in thermal shock, leading to tool failure.

Conclusión

Thermal shock is a serious concern for tungsten carbide tips, particularly in applications where tools are exposed to rapid temperature changes.

The brittle nature of tungsten carbide makes it vulnerable to cracking under thermal stress, which can reduce tool life and increase maintenance costs.

By understanding the factors that contribute to thermal shock and implementing strategies to minimize its effects, industries can ensure that their tungsten carbide tips perform effectively and last longer.

Si desea conocer más detalles sobre alguna empresa, no dude en contactarnos. Contáctanos.