Puntas de carburo de tungsteno are widely used in industrial applications for their exceptional dureza, resistencia al desgastey durabilidad.

However, during installation, improper handling can lead to damage that compromises their performance.

Ensuring that these tips are installed correctly is critical to maximizing their lifespan and efficiency.

In this article, we’ll discuss best practices for handling tungsten carbide tips during installation, the potential risks of improper handling, and how to avoid damage to ensure optimal performance.

Why Proper Handling Matters for Tungsten Carbide Tips

Tungsten carbide tips are tough and resilient materials, but they are also brittle under certain conditions.

Mishandling during installation can cause cracks, chips, or even complete breakage, rendering the tips ineffective.

Proper handling ensures that the tips perform as expected, providing high efficiency and reducing the risk of early failure.

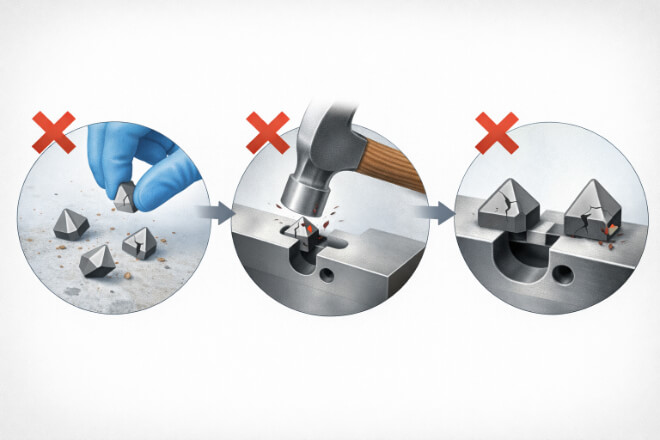

1). Sensitivity to Impact

Despite being one of the hardest materials available, tungsten carbide is sensitive to impact.

A sudden force, such as dropping the tip onto a hard surface, can cause microfractures or even visible cracks, which can reduce the tip’s performance and lifespan.

Example: Dropping a tungsten carbide tip on a concrete floor can cause chips or cracks on its edges, affecting its cutting efficiency.

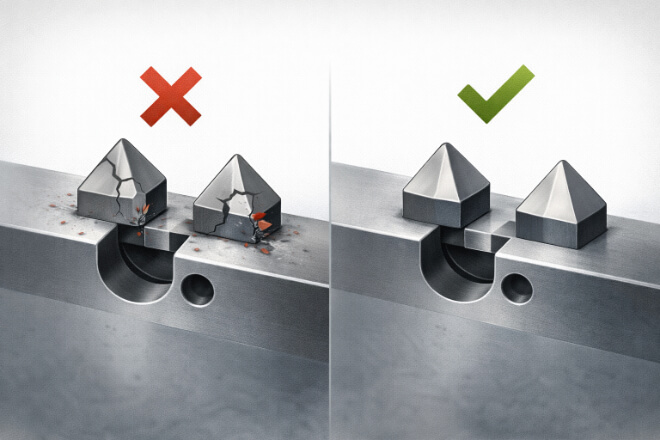

2). Risk of Misalignment

Misalignment during installation can cause uneven wear and unnecessary stress on the tungsten carbide tip.

Over time, this can lead to premature failure or reduced effectiveness in the equipment.

Example: A misaligned tip in a cutting tool may lead to uneven cutting, which can cause excessive wear on the tip and the workpiece.

3). Incorrect Tooling

Using the wrong tooling for installation can cause damage to the tungsten carbide tips.

For example, using a tool that applies too much pressure or does not properly fit the tip may result in deformation or fracture.

Example: Using the wrong tool to fit the tungsten carbide tip into place can cause cracks or stress points that weaken the tip’s durability.

By following the right procedures, these risks can be minimized, ensuring the tungsten carbide tips maintain their performance and last longer.

Best Practices for Handling Tungsten Carbide Tips During Installation

1). Use Protective Gloves

Always wear protective gloves when handling tungsten carbide tips. Gloves help prevent contamination from oils or chemicals on your hands, which can affect the performance of the tips.

They also reduce the risk of dropping the tips due to accidental slips.

Consejo: Use gloves made from materials that provide a good grip to prevent the tips from slipping during installation.

2). Store Tips in Proper Containers

Before installation, tungsten carbide tips should be stored in protective containers or cases to prevent them from coming into contact with hard surfaces.

These containers should be cushioned to avoid any impact damage, such as cracks or chips.

Consejo: Keep the tips in their original packaging or a padded storage container until ready for installation.

3). Use the Correct Installation Tools

Using the correct tools is essential for ensuring proper installation. Tools like proper wrenches or specialized inserts for fitting tungsten carbide tips help avoid unnecessary pressure or impact during installation.

Consejo: Make sure that the installation tool is designed specifically for tungsten carbide tips to avoid applying uneven pressure.

4). Handle with Care During Installation

During installation, handle the tungsten carbide tips gently. Avoid dropping or knocking the tips against any hard surfaces.

Ensure that the installation environment is clean and free from debris that could scratch or damage the tips.

Consejo: If the tips are being installed in machinery, ensure that the installation area is clean and that no metal debris is present that could cause damage during the process.

5). Align Properly

Ensure the tungsten carbide tip is properly aligned before installation.

Misalignment can cause uneven wear or damage to both the tip and the equipment. Using alignment tools can help position the tip correctly for installation.

Consejo: Use alignment jigs or guides to help position the tip accurately, reducing the risk of misalignment during installation.

6). Check for Cracks or Defects

Before installing a tungsten carbide tip, carefully inspect it for any visible cracks or defects.

Any tip with visible damage should be replaced immediately, as even small cracks can grow and lead to complete failure during operation.

- Consejo: Perform a visual inspection and use magnification tools to ensure the tip is free from any microfractures or chips before installation.

Common Mistakes to Avoid When Installing Tungsten Carbide Tips

1). Dropping the Tips

One of the most common mistakes is dropping the tungsten carbide tips onto hard surfaces, which can cause cracks or chips. Always store and handle the tips carefully to avoid this.

2). Applying Excessive Force

Excessive force during installation can lead to deformation or cracks in the tungsten carbide tips. Always use the appropriate tools and apply gentle, even pressure.

3). Not Following Alignment Procedures

Installing the tips without ensuring proper alignment can cause uneven wear and premature failure.

Always take the time to properly align the tips before installation to prevent unnecessary stress on both the tip and the machinery.

4). Ignoring Cleanliness

Failure to clean the installation area or the tips themselves can lead to contamination or damage.

Always make sure the tips and equipment are free from dirt or debris before installation.

5). Improper Storage After Installation

Even after installation, tungsten carbide tips should be stored correctly to prevent future damage.

Make sure the equipment is not exposed to excessive heat, moisture, or vibration, which could affect the tip’s performance.

How Improper Handling Affects Performance

Improper handling during installation can have several long-term effects on the performance of tungsten carbide tips.

Improper handling during installation can have several long-term effects on the performance of tungsten carbide tips.

Damage to the tips can lead to reduced cutting efficiency, increased wear, and even failure of the equipment.

Additionally, improper installation can cause misalignment, leading to uneven force distribution and faster degradation of the tips.

Example: A chip or crack caused by improper installation can lead to the tip breaking during operation, causing downtime and costly repairs.

By ensuring that the correct installation procedures are followed, companies can prevent these issues, resulting in longer-lasting, more efficient tungsten carbide tips.

Conclusión

Proper handling and installation of tungsten carbide tips are essential for maintaining their durability and performance.

By following the best practices, such as using protective gloves, ensuring proper alignment, and using the correct installation tools, companies can avoid damaging the tips and ensure they perform optimally in their applications.

Taking the time to handle tungsten carbide tips with care during installation can lead to reduced wear, longer lifespans, and increased efficiency, ultimately saving time and money.

Si desea conocer más detalles sobre alguna empresa, no dude en contactarnos. Contáctanos.