Herramientas de corte de carburo de tungsteno are essential in many industries—from automotive and aerospace to mold-making and general machining.

These tools are known for their toughness, heat resistance, and long lifespan.

However, one common question from purchasing teams and decision-makers is: Why do tungsten carbide tools cost what they do?

Understanding the pricing of these tools goes far beyond simply looking at the material. In this article, we’ll explain the key factors that influence the cost of tungsten carbide cutting tools.

This will help you make smarter buying decisions and optimize your tooling investment.

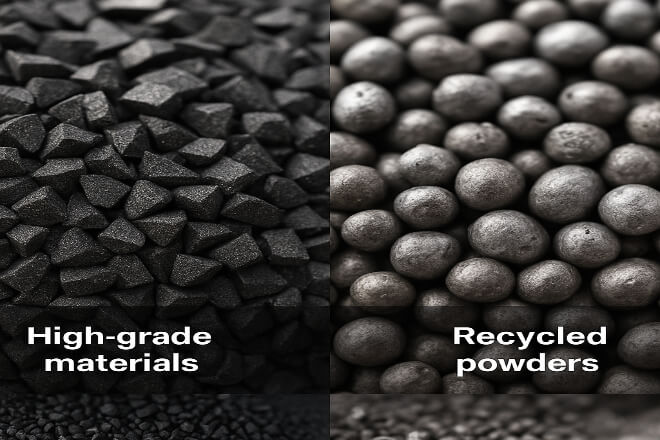

1. Raw Material Quality

One of the biggest cost drivers is the quality of raw materials used to produce tungsten carbide tools.

Tungsten carbide is a composite material made by combining tungsten powder with a binder metal, usually cobalt.

Higher-grade raw materials cost more, but they also produce tools that last longer and perform better.

For example, fine-grain carbide is more wear-resistant and gives a better surface finish, which is critical in high-precision jobs.

Recycled or low-grade powders are cheaper but often result in lower tool life and poor performance.

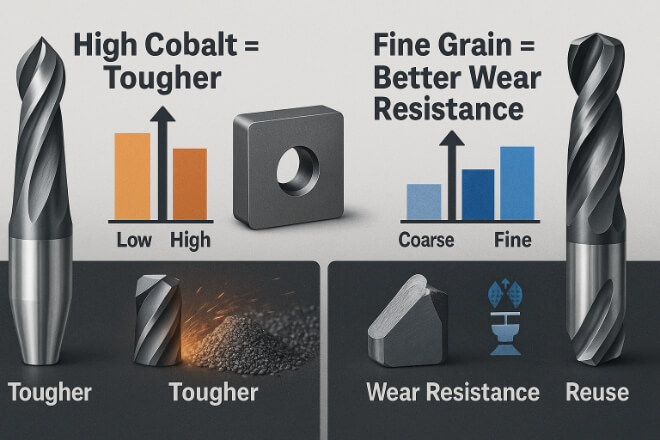

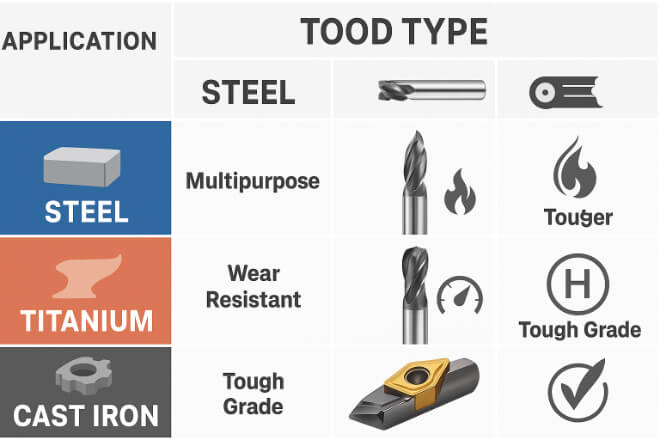

2. Tool Grade and Composition

Not all carbide tools are created equal. Tool grade refers to the ratio of tungsten to cobalt and the grain size of the carbide. Different combinations affect hardness, toughness, and resistencia al desgaste.

Higher cobalt content = more toughness but less dureza

Finer grain = higher wear resistance, better finish

Specialized grades designed for titanium, stainless steel, or cast iron cost more because they offer optimized performance in tough materials.

Choosing the right grade for your application prevents premature tool failure and saves money long term.

3. Precision and Tolerances

The more precise the tool, the more expensive it will be. Why? Because tighter tolerances require advanced grinding equipment, longer production time, and more quality control.

Tools for high-speed CNC applications or those used in mold and die making often require sub-micron accuracy.

If your process needs ultra-precise dimensions, expect a higher price. But this cost is justified if it results in better part quality and less scrap.

4. Coatings and Surface Treatments

Applying advanced coatings to carbide tools significantly boosts their performance. Coatings like TiAlN, TiCN, or CVD diamond can:

Increase heat resistance

Reducir la fricción

Prevent material buildup

Extend tool life by 2x to 5x

However, these coatings add to the cost. The type of coating and the method used (PVD vs. CVD) also influence pricing.

Still, coated tools often provide a better return on investment by reducing downtime and increasing cutting speeds.

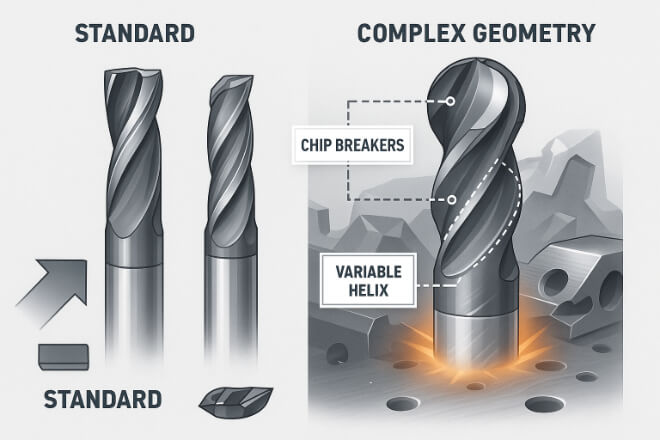

5. Tool Geometry and Design Complexity

More complex tool designs naturally require more engineering and machining time. For example:

Multi-flute tools with chip breakers

Ball nose or radius end molinos

Custom tools made for specific applications

Special geometries that improve chip evacuation or reduce vibration are more expensive to produce—but they improve efficiency, surface finish, and tool life.

Customization always adds value but should be weighed against your production needs and budget.

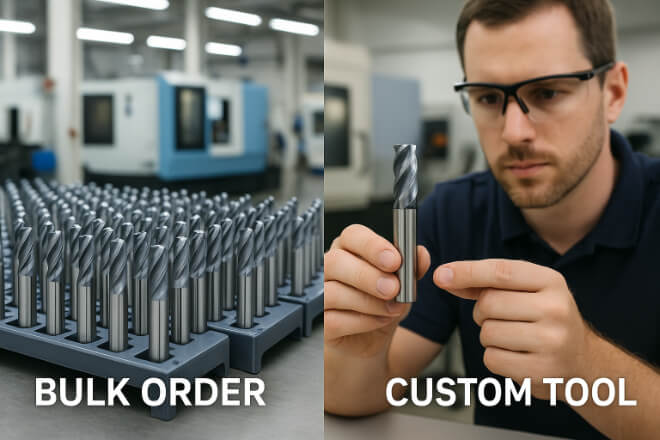

6. Production Volume and Customization

Buying standard tools in large quantities usually means lower unit prices.

On the other hand, custom tools or small batch orders often cost more due to setup time, tooling changes, and limited economies of scale.

Some suppliers charge extra for:

Non-standard diameters or lengths

Custom flute angles

Branding or private labeling

If your company needs customized solutions, expect a higher initial cost, but you might gain significant productivity benefits.

7. Brand, Manufacturing Origin, and Supplier Reputation

The brand and origin of your cutting tools also affect cost. Well-known brands that manufacture in countries with high labor costs may charge a premium, but they usually offer consistent quality and strong technical support.

Conversely, tools from low-cost countries may be cheaper upfront, but performance and reliability can vary widely. It’s important to balance price with proven quality.

8. Application Demands

The tougher the job, the more advanced the tool needs to be. For example:

High-speed cutting requires better heat resistance

Machining abrasive materials needs ultra-hard coatings

Tight tolerances demand precision-ground tools

A general-purpose end mill is cheaper than one made for titanium or Inconel. But using the wrong tool for a difficult job leads to breakage, scrap, and downtime.

The best strategy is to match the tool to the job—not just go with the cheapest option.

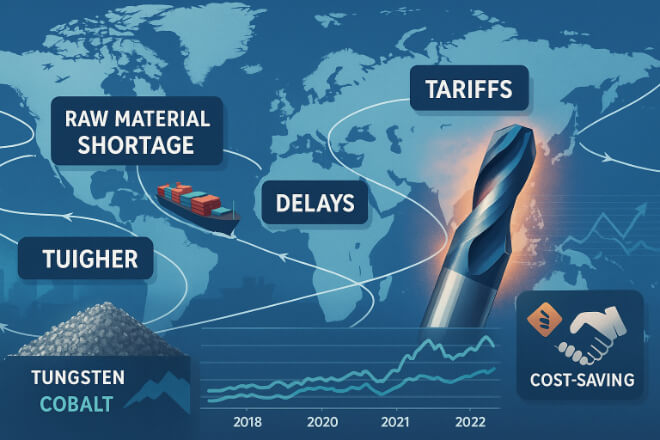

9. Logistics, Tariffs, and Supply Chain Factors

Tool pricing can also be affected by global factors like:

Raw material shortages

Fluctuating tungsten or cobalt prices

Import/export tariffs

Shipping delays or costs

These variables can drive prices up, especially when supply chains are disrupted.

Choosing local or well-stocked suppliers reduces risk and gives you better price stability.

10. Tool Life vs. Tool Price

Perhaps the most overlooked factor is total cost per part. A more expensive carbide tool that lasts five times longer and produces better finishes will cost less in the long run than a cheap tool that breaks early.

Smart companies focus on:

Cost per cut

Cost per part

Downtime reduction

By tracking tool performance, you can justify spending more on high-quality tools that increase productivity.

11. Tips to Optimize Your Carbide Tool Investment

Here’s how you can balance quality and cost:

Work with a trusted supplier Partner with trusted suppliers to find the right tool for your application

Test before scaling up—pilot test a new tool before buying in bulk

Use coated tools for tougher jobs

Consider regrinding high-value tools instead of replacing them

Track performance metrics like parts produced per tool and tool change frequency

Reflexiones finales

The price tag on a tungsten carbide cutting tool doesn’t tell the whole story. Factors like raw material quality, coatings, precision, and tool life all play a role in overall cost and value.

Decision-makers should look beyond just the unit price and consider performance, consistency, and support. By investing wisely in the right tools, you’ll reduce waste, improve efficiency, and maximize your ROI.

For reliable, high-performance carbide tools designed to deliver value, check out Retocar.