In the world of precision machining and industrial manufacturing, herramientas de corte de carburo de tungsteno play a critical role.

These tools are known for their dureza, resistencia al desgaste, and ability to handle high-speed cutting in tough materials.

But there’s one key factor that many decision-makers overlook: the supplier behind the tool.

Choosing the right supplier for your tungsten carbide cutting tools is not just about cost—it’s about consistency, performance, reliability, and long-term value.

A high-quality tool made from premium materials is only as good as the company that stands behind it.

In this guide, we’ll explain why your supplier matters just as much as the tools themselves. We’ll also give you practical tips to help you choose a supplier that fits your business goals.

1. Quality Starts with the Supplier

A reputable supplier ensures that every tool is manufactured using high-quality polvo de carburo de tungsteno, advanced production technology, and strict quality control processes.

The result? Tools that perform consistently in your machines and minimize costly rework.

On the other hand, poor-quality suppliers may cut corners. They might use recycled or impure raw materials, skip important inspections, or outsource production to unverified facilities.

This can lead to inconsistent dimensions, premature tool wear, and tool breakage—issues that directly affect your machining results and bottom line.

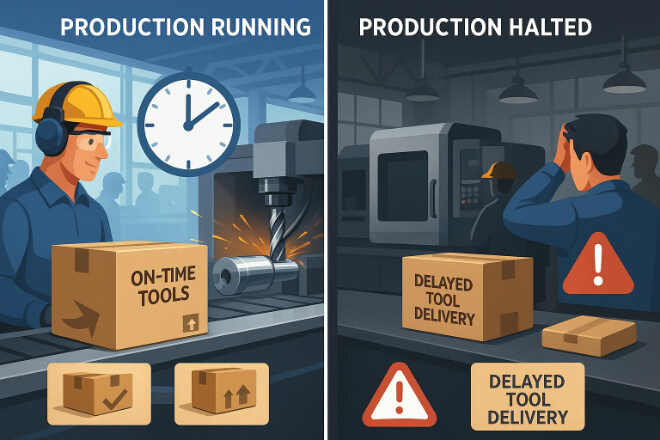

2. Reliable Supply Chain = Less Downtime

Tooling delays can stop your entire production line. A dependable supplier offers stable lead times, strong inventory control, and backup plans to avoid shipping issues.

This is especially important if you run lean manufacturing or rely on just-in-time (JIT) operations.

When you partner with a reliable carbide tool supplier, you’re less likely to face sudden shortages or quality issues that interrupt production.

A strong supplier keeps your operations running smoothly and gives you peace of mind.

3. Technical Support and Customization

Not every machining job is the same. Sometimes you need tools with special geometries, coatings, or grades for specific materials. A good supplier offers technical support to help you:

Choose the right tool grade and coating

Customize tool geometry to improve performance

Optimize cutting parameters for better efficiency

These value-added services can help your shop get more from each tool. If your current supplier just ships catalog items with no engineering help, you might be missing out on real productivity gains.

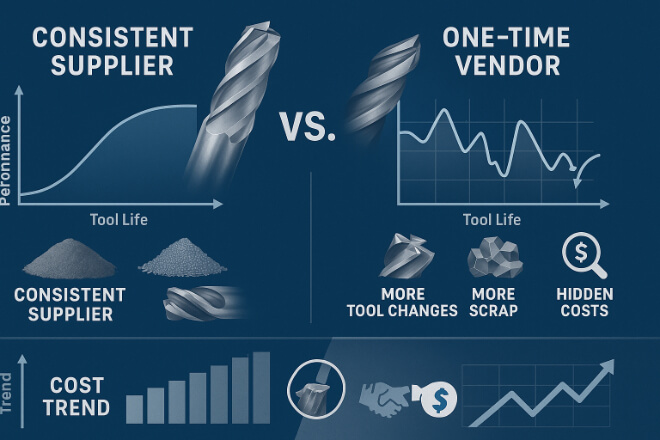

4. Consistency Matters More Than One-Time Cost

It’s tempting to choose the cheapest supplier, especially when budgets are tight. But in the long run, inconsistent tooling causes more problems than it solves.

Inconsistent tools can:

Wear out faster

Require more tool changes

Produce uneven surface finishes

Lead to higher scrap and rework rates

A slightly more expensive tool that performs reliably will save you time, reduce downtime, and produce better parts. Think cost-per-part, not cost-per-tool.

5. Certifications and Manufacturing Standards

Reputable suppliers often hold international certifications like ISO 9001, which shows that they follow quality management standards.

Some also follow industry-specific standards for aeroespacial, médico, o automotive applications.

Certifications prove that a supplier:

Tracks material batches for traceability

Tests hardness and grain size

Measures tool tolerances with precision equipment

These steps reduce variability and ensure that the tools meet performance expectations. If your supplier doesn’t provide quality certificates or test data, that’s a red flag.

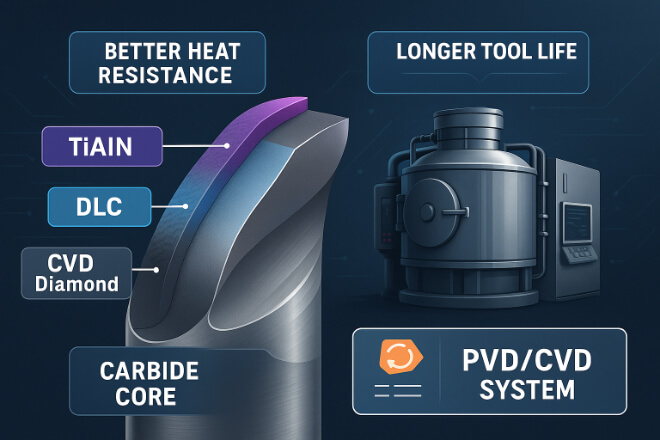

6. Advanced Coating and Manufacturing Technology

Tool coatings can make or break your tool’s performance. The best suppliers invest in state-of-the-art coating lines—like PVD and CVD systems—that apply coatings evenly and at the right thickness.

A good supplier will also:

Offer modern CNC grinding for tight tolerances

Use automated inspection systems for consistency

Provide a range of coatings like TiAlN, DLC, and CVD diamond

If your supplier can’t offer the right coatings for your material or doesn’t keep up with new technology, your machining efficiency could suffer.

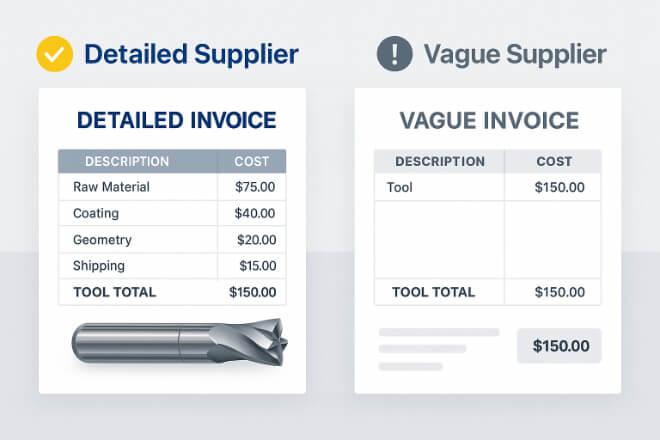

7. Transparent Pricing and Value-Added Services

Price matters, but transparency matters more. Trustworthy suppliers explain what you’re paying for—whether it’s raw material quality, advanced geometry, or a custom coating.

They also provide:

Clear lead times

Honest shipping fees

Options for tool regrinding or recycling

Some suppliers offer tool performance tracking or reports to help you measure ROI. These services help you plan better and reduce total tooling cost.

8. Sustainable and Ethical Sourcing

Tungsten and cobalt—key materials in carbide tools—can come from conflict regions.

Ethical suppliers ensure that their raw materials are responsibly sourced, and that their manufacturing processes minimize waste.

If your company values sustainability, working with the right supplier helps you:

Reduce environmental impact

Meet ESG goals

Avoid reputational risk from unethical sourcing

Ask your supplier about their material sourcing and environmental practices. A good one will have nothing to hide.

9. Global Reach with Local Support

If your business operates globally or across multiple locations, your supplier should be able to support your entire network. Look for a partner that offers:

Global distribution or stocking centers

Local technical support or field engineers

Fast delivery and flexible fulfillment options

This ensures your plants can get tools quickly and avoid production disruptions—no matter where they are.

10. Long-Term Partnership Benefits

The best suppliers are more than just vendors—they’re partners. They work with you to solve problems, improve productivity, and plan for the future.

Long-term relationships bring many benefits:

Better pricing agreements

Early access to new products

Priority support for urgent orders

Custom tool development based on your needs

If your supplier only focuses on transactions—not your success—it may be time to reevaluate.

Reflexiones finales

In today’s competitive manufacturing world, choosing the right supplier for your tungsten carbide cutting tools is a strategic decision—not just a purchasing one.

The right supplier offers more than good prices. They deliver consistent quality, fast response times, technical expertise, and long-term value. They help you stay productive, reduce costs, and improve the quality of your parts.

Don’t settle for just any tooling vendor. For high-performance carbide tools backed by expert support, visit Retopz and see how the right supplier can make all the difference.