In the world of precision machining, cutting tool performance is everything.

Whether you’re shaping metal parts for aeroespacial, automotor, o médico devices, you need tools that stay sharp, cut clean, and last long. That’s where tungsten carbide comes in.

Herramientas de corte de carburo de tungsteno are known for their extreme dureza, excellent resistencia al desgaste, and reliability under pressure.

But what exactly makes tungsten carbide so special—and how does it actually improve cutting tool performance?

¿Qué es el carburo de tungsteno?

Tungsten carbide is a compound made from two elements: tungsten (W) and carbon (C).

When combined under high pressure and heat, they form a material that is nearly as hard as diamonds.

Most tungsten carbide cutting tools are not made of pure tungsten carbide alone.

They also include a metal binder, usually cobalt, which holds the particles together and gives the material some toughness.

Why does this matter? Because it creates a perfect balance: dureza to cut through tough materials and toughness to resist breaking during cutting.

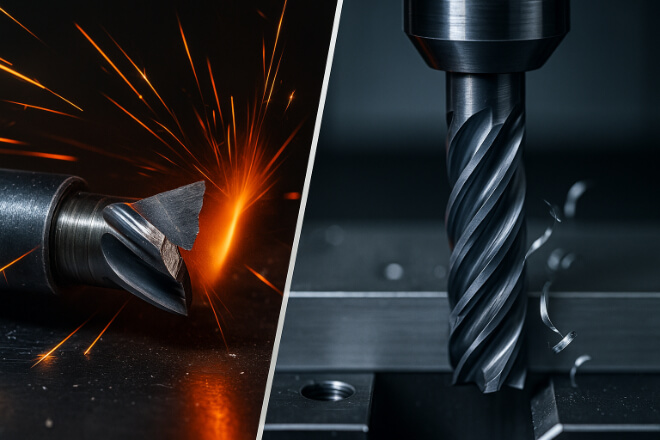

Hardness That Outperforms High-Speed Steel

One of the biggest advantages of tungsten carbide is its hardness. Compared to high-speed steel (HSS), tungsten carbide is much harder.

| Material | Dureza (Vickers HV) |

|---|---|

| Acero de alta velocidad | 800 – 1000 HV |

| Carburo de tungsteno | 1600 – 2000 HV |

What this means for you:

Harder tools can handle harder materials. Tungsten carbide cutting tools can easily cut stainless steel, titanium, cast iron, and other high-strength alloys.

They stay sharp longer and reduce the need for frequent replacements.

Better Wear Resistance = Longer Tool Life

Tool wear is a major issue in machining. The longer a tool lasts, the more value it delivers.

Tungsten carbide is extremely resistente al desgaste, especially when used with advanced coatings like TiAlN or DLC.

Esto significa:

Menos cambios de herramientas

Menos tiempo de inactividad

Lower tooling cost over time

Tungsten carbide can often outlast HSS tools by 10x or more in demanding operations.

Withstands High Cutting Temperatures

Machining generates a lot of heat. If your tool can’t handle high temperatures, it softens, dulls, or even breaks.

Tungsten carbide can withstand temperatures up to 1000°C (1832°F) without losing dureza.

This allows:

Faster cutting speeds

Dry machining or reduced coolant use

More consistent surface finish

For high-speed machining, tungsten carbide tools are the gold standard.

Improved Cutting Accuracy

When cutting hard materials, stability is key. Tungsten carbide tools are stiff and resist vibration better than softer materials.

This leads to:

More accurate cuts

Tighter tolerances

Smoother surfaces

Less tool chatter

In industries like aerospace and medical devices, where accuracy is non-negotiable, carbide tools make a big difference.

Opciones versátiles de geometría de herramientas

Tungsten carbide allows for very precise grinding and custom tool geometry.

Manufacturers can create a wide variety of shapes—flat end mills, ball nose, drills, reamers, and inserts—each designed for a specific task.

Los beneficios incluyen:

Optimized chip control

Reduced cutting forces

Better finish in difficult-to-machine materials

This versatility helps machine shops improve performance in everything from roughing to finishing operations.

Supports Coatings for Enhanced Performance

Carbide is also an excellent base for applying coatings that further improve tool life and performance.

Popular coatings include:

TiAlN (Titanium Aluminum Nitride): Adds heat resistance

DLC (Diamond-Like Carbon): Reduces friction

CVD Diamond: Ideal for non-ferrous materials like graphite or composites

These coatings make carbide tools even better by protecting the cutting edge and allowing faster speeds.

Reduced Tool Breakage

Tool breakage not only costs money—it can ruin the workpiece and cause downtime.

Tungsten carbide tools, when used correctly, are less likely to break compared to brittle materials like ceramics.

Thanks to the tough cobalt binder, carbide tools can handle:

Cortes interrumpidos

Tough alloys

Poor machining conditions

If reliability matters to your production line, tungsten carbide delivers.

Ideal for Automated and High-Volume Production

In automated production lines or CNC machining centers, the last thing you want is tool failure. You need tools that work reliably across long runs.

Tungsten carbide’s long life and consistency make it ideal for:

CNC turning and milling

Automated part finishing

Unattended machining shifts

With carbide tools, you can run longer without supervision and still maintain quality output.

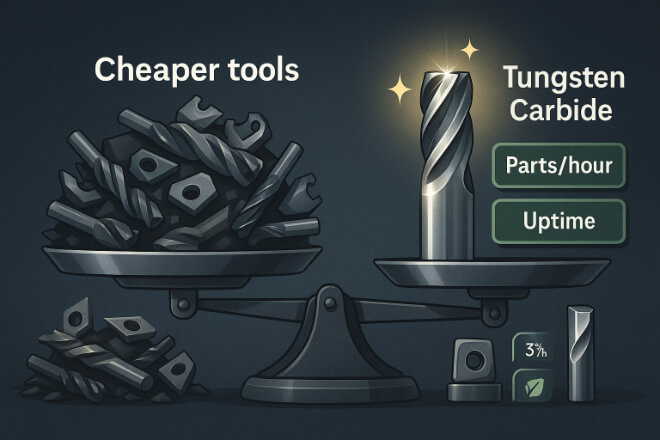

Overall Value Over Tool Cost

At first glance, tungsten carbide tools may seem expensive. But when you look at the cost-per-part instead of cost-per-tool, the math makes sense.

Here’s why:

Longer tool life = fewer replacements

Faster speeds = more parts per hour

Better finish = less post-processing

Less downtime = higher machine efficiency

Over time, the total cost of ownership for carbide tools is often lower than cheaper tools that wear out quickly.

Where to Use Tungsten Carbide Cutting Tools

These tools are perfect for:

Aeroespacial parts (titanium, Inconel)

Automotor components (engine blocks, gears)

Médico devices (surgical tools, implants)

Tool and die making

Hard plastics and composites

Basically, if you’re working with tough materials, tungsten carbide is your best choice.

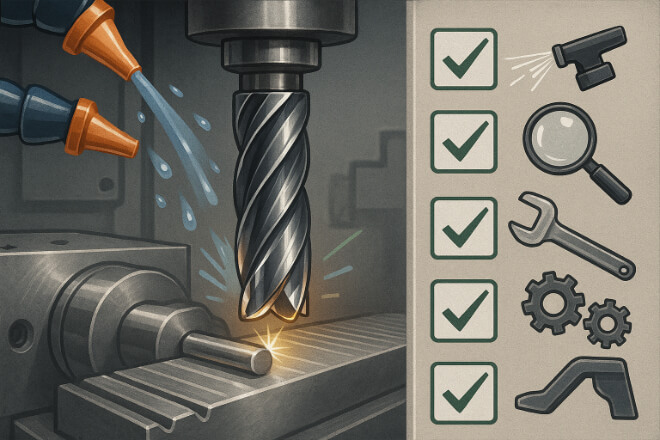

Maintenance Tips for Long Tool Life

To get the most out of your carbide tools:

Use the correct feeds and speeds

Apply coolant or use coated tools for dry machining

Avoid sudden tool plunges

Use the right tool holders

Inspect and replace before tools wear out completely

A little care can extend tool life even further.

Reflexiones finales

Tungsten carbide is more than just a hard material—it’s a performance booster for your cutting tools.

From lasting longer to cutting cleaner and faster, it helps manufacturers stay competitive in a demanding market.

If you’re still using high-speed steel or lower-grade tools for tough jobs, it might be time to make the switch. Tungsten carbide cutting tools aren’t just better—they’re smarter for business.

Looking for top-quality tungsten carbide tools backed by support and performance? Visit Retopz for reliable solutions tailored to your machining needs.