En el mundo industrial, las máquinas y herramientas se enfrentan a constantes tensiones, fricción y calor. Las piezas que no soportan estas condiciones se desgastan rápidamente, lo que provoca tiempos de inactividad y elevados costes de sustitución.

Es por eso que muchas empresas confían en el carburo de tungsteno, un material famoso por su excepcional durabilidad.

Este artículo explica la ciencia que hace que el carburo de tungsteno sea tan resistente, por qué dura más que la mayoría de los otros materiales y cómo las industrias se benefician de su uso.

¿Qué es el carburo de tungsteno?

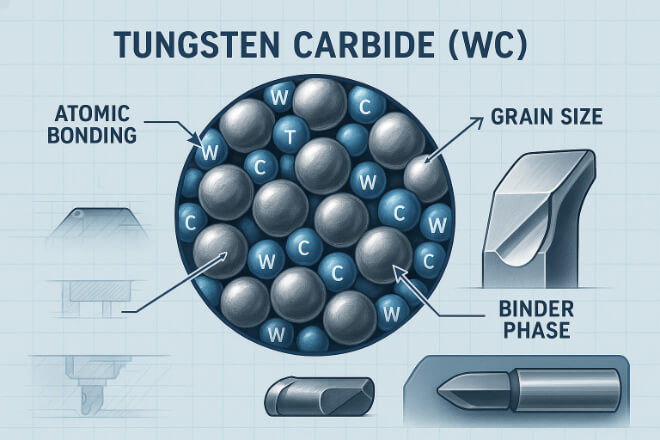

El carburo de tungsteno es un compuesto químico formado por átomos de tungsteno (W) y carbono (C). Al combinarse, crean un material muy duro y denso.

La mayoría de las piezas industriales de carburo de tungsteno también contienen un aglutinante metálico, generalmente cobalto o níquel, para agregar dureza.

Características principales del carburo de tungsteno:

Extremadamente duro, casi tan duro como el diamante.

Alta densidad: más pesado que el acero.

Fuerte y resistente: resiste grietas y roturas.

Resistente al desgaste – dura más tiempo bajo estrés

La ciencia de su durabilidad

La durabilidad del carburo de tungsteno proviene de la estructura de sus átomos y la forma en que se fabrica.

1) Enlace atómico

El tungsteno y el carbono forman fuertes enlaces covalentes, creando una estructura cristalina extremadamente difícil de romper. Esta estructura es lo que le da al carburo de tungsteno su... dureza.

2) Tamaño del grano

Los tamaños de grano más pequeños hacen que el material sea más duro y resistente al desgaste. Los carburos de grano fino se utilizan en precisión. Herramientas de corte donde los bordes afilados son esenciales.

3) Fase aglutinante

El aglutinante metálico (cobalto o níquel) mantiene unidos los granos duros de carburo. Una mayor cantidad de aglutinante implica mayor tenacidad, pero ligeramente menor dureza. Una menor cantidad de aglutinante implica mayor dureza, pero menor resistencia al impacto.

Dureza: la clave para una larga vida

La dureza es la capacidad de un material para resistir rayaduras e indentaciones. El carburo de tungsteno tiene una puntuación de 8,5 a 9 en la escala de Mohs, justo por debajo del diamante.

Esta dureza permite que las herramientas de corte, las brocas de minería y las piezas de desgaste mantengan su forma y filo durante mucho más tiempo que el acero u otros materiales.

En el mecanizado de alta velocidad, esto significa menos cambios de herramientas y menos tiempos de inactividad.

Resistencia al desgaste: lucha contra la fricción

Resistencia al desgaste es fundamental en industrias como la minería, petróleo y gasy fabricación. El carburo de tungsteno resiste la abrasión porque:

Los granos duros evitan el corte por otros materiales.

La estructura densa resiste daños en la superficie.

Mantiene su dureza incluso a altas temperaturas.

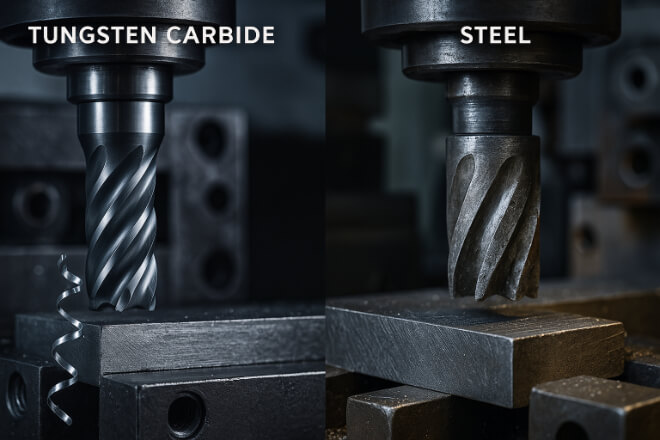

En comparación con el acero para herramientas, el carburo de tungsteno puede durar de 10 a 20 veces más en muchas aplicaciones.

Resistencia al calor: trabajar en condiciones extremas

Al mecanizar o taladrar, el calor se acumula rápidamente. Muchos materiales pierden dureza cuando se calientan, pero el carburo de tungsteno permanece duro hasta 1.000 °C (1.832 °F).

Esta resistencia al calor es la razón por la que las herramientas de carburo de tungsteno se utilizan para corte a alta velocidad, conformado de metales y minería en entornos extremos.

Resistencia a la corrosión: sobrevivir en entornos hostiles

El carburo de tungsteno resiste muchos productos químicos, lo que lo hace ideal para aplicaciones en yacimientos petrolíferos, plantas químicas y entornos marinos.

Si bien el carburo de tungsteno puro es muy resistente a la corrosión, el metal aglutinante puede verse afectado, por lo que se utilizan grados especiales con aglutinantes de níquel en entornos altamente corrosivos.

Dureza: Manejo de impactos y golpes

Si bien la dureza es importante, los materiales también necesitan tenacidad — la capacidad de absorber energía sin romperse.

El aglutinante del carburo de tungsteno proporciona tenacidad, lo que le permite soportar vibraciones, golpes e impactos en herramientas y piezas de desgaste.

Aplicaciones industriales de la durabilidad del carburo de tungsteno

La combinación de carburo de tungsteno de dureza, resistencia al desgaste, resistencia al calor y tenacidad lo hace esencial en muchas industrias:

Herramientas de corte de metal: insertos, fresas, brocas

Herramientas de minería: brocas, picos de corte, puntas de trituradora

Equipos para petróleo y gas: asientos de válvulas, sellos de bombas

Herramientas de construcción: dientes para fresado de carreteras, herramientas de excavación

Piezas de desgaste: bujes, boquillas, matrices

Comparación con otros materiales duraderos

| Material | Dureza | Resistencia al desgaste | Resistencia al calor |

|---|---|---|---|

| Carburo de tungsteno | Muy alto | Excelente | Excelente |

| Acero para herramientas | Medio | Bien | Justo |

| Cerámica | Muy alto | Excelente | Bien |

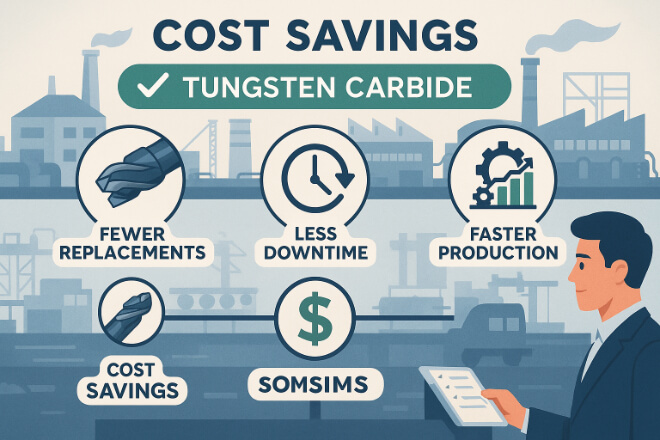

Cómo la durabilidad ahorra costos a las industrias

Aunque los componentes de carburo de tungsteno cuestan más al principio, ahorran dinero a largo plazo porque:

Reducir la frecuencia de reemplazo

Minimizar el tiempo de inactividad

Reducción de los costes de mantenimiento

Mejorar la velocidad y la consistencia de la producción

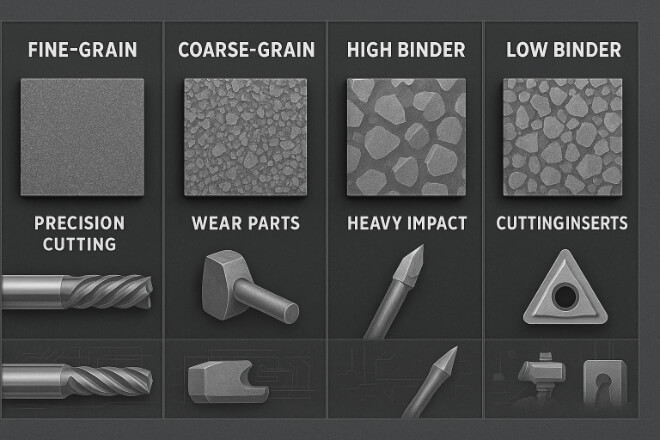

Cómo elegir el grado adecuado de carburo de tungsteno

No todos los carburos de tungsteno son iguales. Elegir el grado adecuado para su aplicación garantiza la máxima durabilidad.

Grados de grano fino: ideales para herramientas de precisión y resistencia al desgaste.

Grados de grano grueso: mejores para aplicaciones de alto impacto.

Alto contenido de aglutinante: mayor tenacidad, menor dureza.

Bajo contenido de aglutinante: mayor dureza, menor tenacidad.

Consejos de mantenimiento para preservar la durabilidad

Incluso los materiales duraderos se benefician de un mantenimiento adecuado:

| Consejo | Beneficio |

|---|---|

| Inspecciones regulares | Identificar el desgaste prematuro y prevenir fallas |

| Lubricación adecuada | Reduce la fricción y la acumulación de calor. |

| Manejo correcto | Prevenir astillas o grietas |

| Limpieza después del uso | Eliminar residuos y agentes corrosivos |

Innovaciones futuras en la durabilidad del carburo de tungsteno

La investigación se centra en mejorar el carburo de tungsteno mediante:

Carburos nanoestructurados para mayor resistencia

Recubrimientos avanzados para reducir la fricción

Programas de reciclaje para recuperar tungsteno de herramientas usadas

Estas innovaciones harán que el carburo de tungsteno sea aún más rentable y sostenible.

Conclusión

La excepcional durabilidad del carburo de tungsteno proviene de su estructura atómica, dureza, tenacidad y resistencia al calor y la corrosión.

Para las industrias que dependen de herramientas y piezas de alto rendimiento, ofrece una manera de reducir costos, disminuir el tiempo de inactividad y mejorar la productividad.

Al comprender la ciencia detrás de su durabilidad, los tomadores de decisiones pueden tomar mejores decisiones sobre dónde y cómo utilizar carburo de tungsteno en sus operaciones.

Si desea conocer más detalles sobre alguna empresa, no dude en contactarnos. Contáctanos.