Centrifugal pumps are used across many industries, from chemical plants to power stations and water treatment facilities.

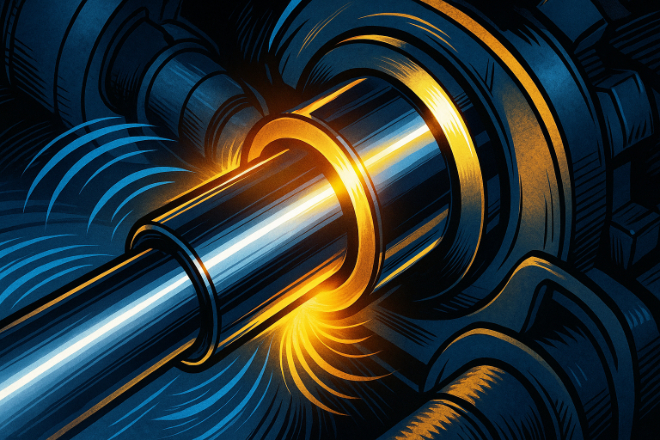

Their shafts rotate at high speed and face continuous friction, load, and fluid exposure. Tungsten carbide bushings play an essential role in protecting the shaft and ensuring smooth, long-term operation.

This article explains the best tungsten carbide bushing options for centrifugal pump shafts, including grades, designs, and performance differences.

Why Tungsten Carbide Is Ideal for Centrifugal Pump Shafts

Centrifugal pumps rely on stable shaft rotation. Any friction, vibration, or shaft movement can reduce efficiency and shorten pump life.

Tungsten carbide bushings are chosen because they provide:

Alto dureza

Excelente resistencia al desgaste

Low friction against the shaft

Larga vida útil

Stable performance at high speed

When pumps run for many hours per day, these advantages help reduce downtime and maintenance cost.

Operating Challenges in Centrifugal Pumps

Centrifugal pump shafts face both mechanical and environmental stress. Choosing the right bushing helps prevent premature failure.

Typical challenges include:

Abrasive solids in fluid flow

High operating temperature

High rotational speed

Chemical corrosion

Shaft vibration or misalignment

Poor lubrication conditions

Tungsten carbide handles these challenges better than steel, bronze, or polymer bushings.

Best Tungsten Carbide Grades for Pump Shafts

Not all tungsten carbide is the same. The performance depends on the binder type, binder percentage, and grain size.

Here are the most suitable grades for centrifugal pump bushings:

1). WC-Co Grades (Cobalt Binder)

Most common industrial choice

Muy alto dureza

Best for abrasive environments

Bien tenacidad allowing shock resistance

2). WC-Ni Grades (Nickel Binder)

Excelente Resistencia a la corrosión

Better performance in seawater, brine, and chemical plants

Lower risk of binder corrosion compared to cobalt

3). Submicron Grain Tungsten Carbide

Ultra-high hardness

Muy baja fricción

More precise surface finish

Ideal for high-speed pump shafts

4). Grade Comparison Table

| Calificación | Tipo de carpeta | Strength | Best Application |

|---|---|---|---|

| WC-6Co | Cobalt | Alta resistencia al desgaste | Abrasive fluids, mining slurry |

| WC-12Co | Cobalt | Better toughness | General industrial pumps |

| WC-Ni (6–12%) | Nickel | Resistencia superior a la corrosión | Seawater, chemical plants |

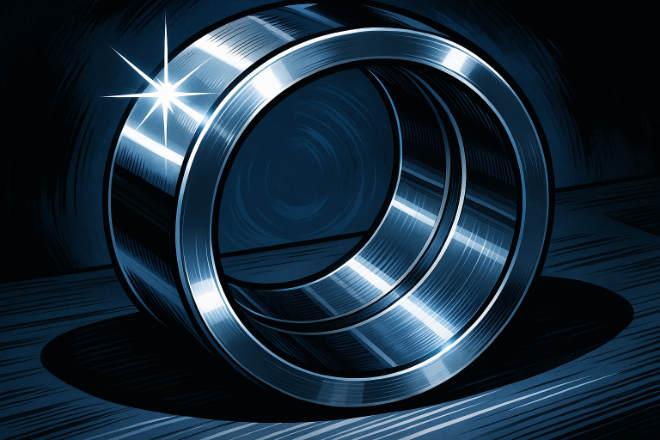

Surface Finish Requirements for Pump Shaft Bushings

Surface finish plays a major role in friction, lubrication, and overall pump reliability.

Typical surface finish requirements

Bearing surface: Ra 0.1–0.2 µm

Seal surface: Ra ≤ 0.05 µm

Shaft mating surface: smooth, polished, and free of scratches

A smoother finish reduces heat and improves pump efficiency.

Fit and Clearance Recommendations

Choosing the correct clearance between the shaft and bushing helps avoid failure. Too tight, and the pump overheats. Too loose, and vibration increases.

Typical Clearance Chart

| Shaft Diameter | Recommended Clearance | Notes |

|---|---|---|

| ≤ 50 mm | 0.02–0.05 mm | For high-speed shafts |

| 50–100 mm | 0.03–0.07 mm | General centrifugal pumps |

| ≥ 100 mm | 0.05–0.10 mm | Large industrial pumps |

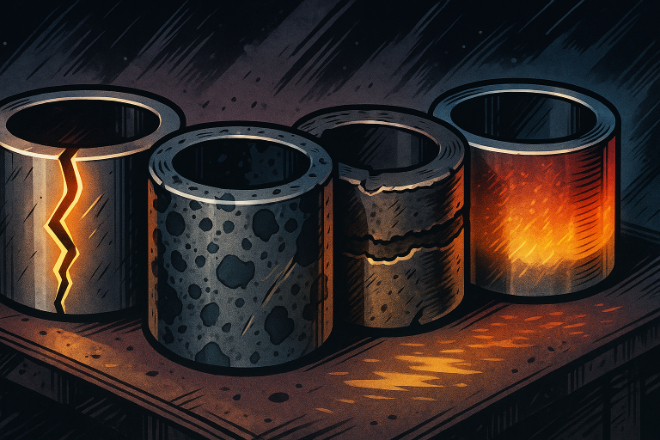

Key Failure Modes and How to Avoid Them

Understanding the main failure modes helps decision-makers choose the right material and prevent downtime.

1). Common failure modes

Abrasive wear

Thermal cracking

Shaft scoring

Binder leaching

Vibration damage

Chemical corrosion

2). How to reduce failure risk

Select proper tungsten carbide grade

Ensure correct clearance

Maintain clean lubrication

Usar corrosion-resistant WC-Ni in aggressive fluids

Check alignment during installation

How to Select the Best Supplier

A reliable supplier ensures the bushings meet industrial performance requirements.

Supplier selection checklist

Provides cobalt and nickel binder options

Can produce micrograin and submicron carbide

Offers complete test reports: dureza, densidad, microstructure

Has HIP sintering capability

Experience in heavy-duty centrifugal pumps

Provides engineering support for custom designs

Selecting a qualified supplier ensures consistency, long service life, and fewer pump failures.

Conclusión

Tungsten carbide bushings are one of the best solutions for centrifugal pump shafts due to their superior hardness, wear resistance, and stability.

By choosing the right grade, clearance, surface finish, and supplier, OEMs and industrial users can achieve long-term pump reliability and reduce operating costs.

Si desea conocer más detalles sobre alguna empresa, no dude en contactarnos. Contáctanos.