When it comes to Herramientas de corte used in manufacturing, the word “carbide” gets thrown around a lot. But what does it really mean?

More importantly, is there a difference between “carbide” and “tungsten carbide”?

If you’re a decision-maker in the machining or tooling industry, understanding the materials behind your cutting tools is key to better performance, cost control, and long-term results.

In this blog, we’ll explore the differences between carbide and tungsten carbide, explain why the distinction matters, and help you make smarter decisions when choosing tooling materials for your operations.

1. What Is Carbide?

“Carbide” is a general term often used to describe a class of very hard materials made from carbon and a less electronegative element.

In the tooling world, however, it usually refers to tungsten carbide.

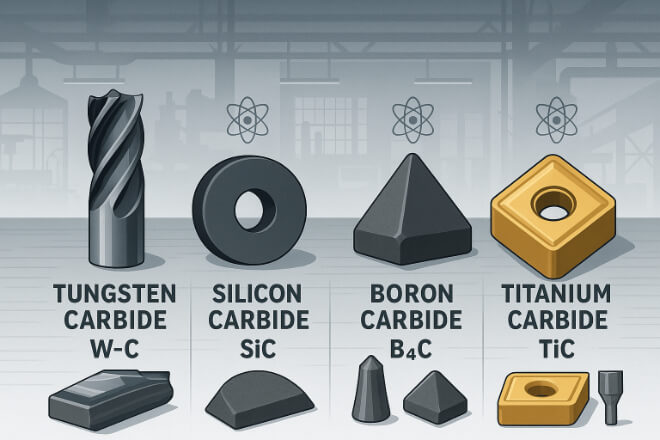

But it’s important to note that carbide can include materials like:

Tungsten carbide (W-C)

Silicon carbide (SiC)

Boron carbide (B4C)

Titanium carbide (TiC)

Out of these, tungsten carbide is the most commonly used material for metal cutting tools due to its high hardness and wear resistance.

2. ¿Qué es el carburo de tungsteno?

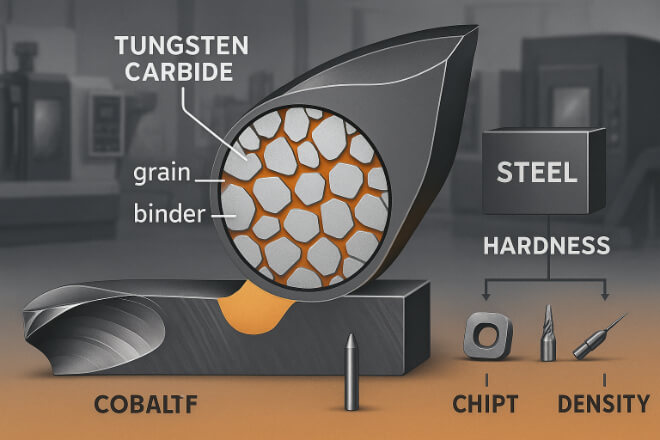

Tungsten carbide is a compound made from tungsten (W) and carbon (C). It’s produced by combining fine tungsten powder with carbon and heating it to high temperatures.

The result is a dense, gray material that’s twice as stiff as steel and incredibly resistant to wear.

But that’s not the whole story. Most cutting tools labeled as “tungsten carbide” are actually a composite—tungsten carbide grains held together by a binder, usually cobalt. This gives the tool tenacidad, preventing it from being too brittle.

This composite material is often referred to as cemented carbide.

3. Key Differences: Carbide vs Tungsten Carbide

Although many use these terms interchangeably, there’s a distinction when it comes to tool quality and precision.

1). Composition:

Carbide: A general term for several hard compounds.

Tungsten Carbide: Specifically refers to the W-C compound used in most cutting tools.

2). Performance:

Tungsten carbide tools are optimized for high-speed cutting, lasting longer under pressure and heat.

Generic “carbide” tools may vary in performance depending on what they’re made from.

3). Applications:

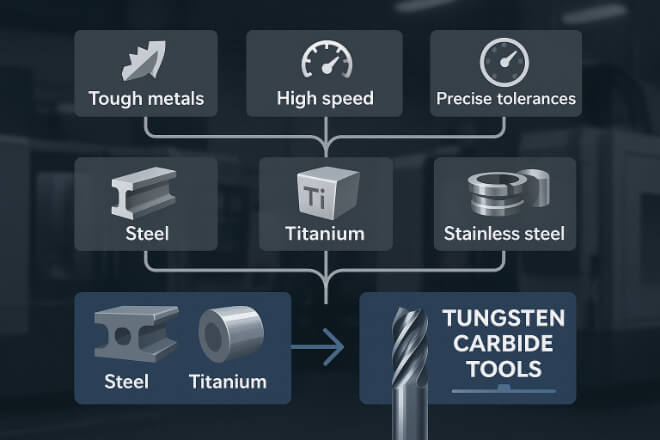

Tungsten carbide is ideal for cutting hard metals like stainless steel, cast iron, and titanium.

Other carbides like silicon carbide are more common in grinding or non-metal cutting applications.

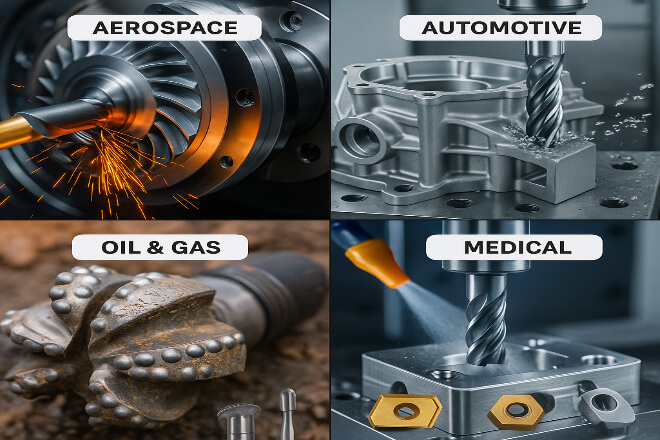

Why Tungsten Carbide Dominates the Cutting Tool Market

Tungsten carbide’s popularity isn’t by accident. It’s trusted in industries like:

Its key advantages:

Alto dureza for long wear life

Heat resistance for high-speed applications

Customizability through different grain sizes, coatings, and binders

These traits make tungsten carbide cutting tools a smart investment for manufacturers that want consistency, precision, and cost control.

5. How Carbide Grade and Microstructure Affect Performance

Not all tungsten carbide tools are created equal. The grade (which includes grain size, cobalt content, and additives) impacts how the tool behaves.

| Característica | carburo de grano fino | carburo de grano grueso |

|---|---|---|

| Dureza | Más alto | Más bajo |

| Tenacidad | Más bajo | Más alto |

| Resistencia al desgaste | Excelente | Bien |

| Solicitud | Finishing & precision | Roughing & heavy cuts |

For decision-makers, knowing the grade matters. A finishing tool might need fine-grain carbide, while a roughing tool may benefit from coarser grains with higher tenacidad.

6. The Role of Coatings on Tungsten Carbide

Tungsten carbide tools are often coated to improve performance even further. Common coatings include:

TiAlN (Titanium Aluminum Nitride) – Good for high heat

DLC (Diamond-Like Carbon) – Excellent for non-ferrous metals

CVD Diamond – Ideal for high-abrasion materials like carbon fiber

Coatings reduce friction, extend tool life, and allow for higher speeds without tool breakdown.

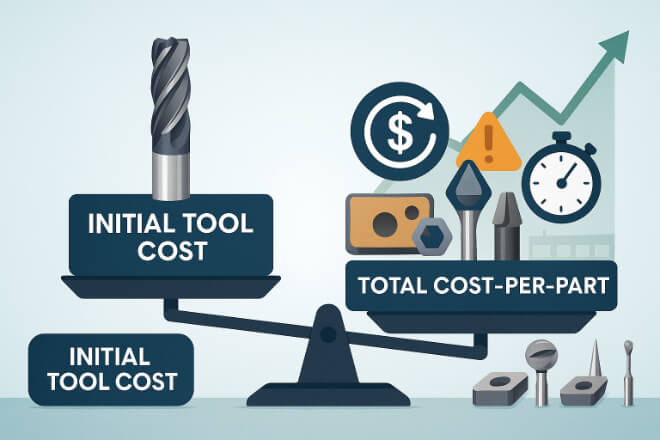

7. Cost Differences and Long-Term Value

At first glance, tungsten carbide tools might seem more expensive than high-speed steel (HSS) or other generic carbide tools. But the long-term cost is often lower due to:

Menos reemplazos

Menos tiempo de inactividad

Mejor calidad de las piezas

Higher feed and speed rates

Cost-per-part is more important than cost-per-tool.

8. Misunderstandings in the Market

Some suppliers advertise “carbide tools” that are low-grade or recycled tungsten carbide, which don’t offer the same durability or precision. Always check:

Supplier transparency

ISO certifications

Tool performance data

9. When to Choose Tungsten Carbide Over Other Options

You should use tungsten carbide cutting tools when:

Working with tough metals

Running high-speed machining operations

Needing consistent tolerances

Trying to reduce tool changeover and scrap rate

For soft materials or very simple jobs, HSS or uncoated tools might still work. But for demanding production environments, carburo de tungsteno is the clear winner.

10. Making the Right Choice for Your Operations

As a decision-maker, the right tooling choice can impact productivity, machine wear, and profit margins.

Hazte estas preguntas:

Are your current tools lasting long enough?

Do you see frequent tool failure or poor finishes?

Are your speeds and feeds limited by tool material?

If the answer to any of these is yes, it’s worth evaluating your current tooling and considering the switch to premium tungsten carbide cutting tools.

Reflexiones finales

The terms “carbide” and “tungsten carbide” are often used the same way, but they’re not truly the same.

In the world of cutting tools, understanding this difference can help you make better purchasing decisions, improve performance, and boost ROI.

If you’re aiming for better precision, higher productivity, and long-term savings, tungsten carbide is the material to trust.

Si desea conocer más detalles sobre alguna empresa, no dude en contactarnos. Contáctanos.