Las herramientas de corte de carburo de tungsteno son conocidas por su resistencia, dureza y larga vida útil. Sin embargo, incluso estas herramientas de alto rendimiento pueden presentar problemas durante su uso. Comprender los problemas comunes y saber cómo solucionarlos puede ayudarle a prolongar la vida útil de las herramientas, reducir el desperdicio y mantener sus operaciones funcionando sin problemas.

En este blog, exploraremos los problemas más comunes con las herramientas de corte de carburo de tungsteno y ofreceremos soluciones sencillas y eficaces. Ya sea que corte metal, madera o materiales compuestos, esta guía le ayudará a evitar errores y a obtener el máximo rendimiento de sus herramientas.

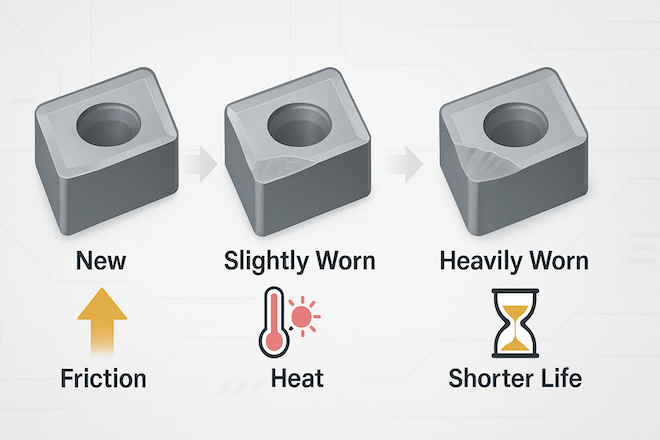

1. El desgaste de las herramientas se produce demasiado rápido

🛠 Problema:

Aunque el carburo de tungsteno es duro, el filo puede desgastarse más rápido de lo esperado. Esto puede provocar:

Mal acabado superficial

Se necesita fuerza adicional durante el corte

Reemplazo frecuente de herramientas

✅ Solución:

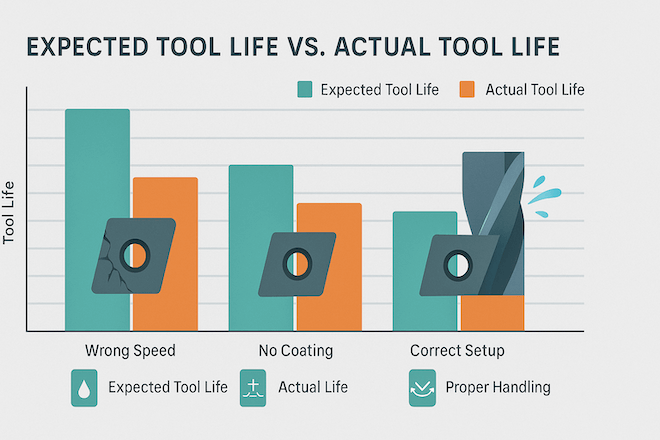

Verifique la velocidad de corte y el avance. Ir demasiado rápido puede aumentar el calor y el desgaste.

Utilice herramientas de carburo recubiertas para una mejor resistencia al desgaste.

Aplique el refrigerante adecuado para reducir el calor y prolongar la vida útil de la herramienta.

Puede obtener más información aquí:

👉 Por qué las herramientas de corte de carburo de tungsteno tienen una resistencia al desgaste superior

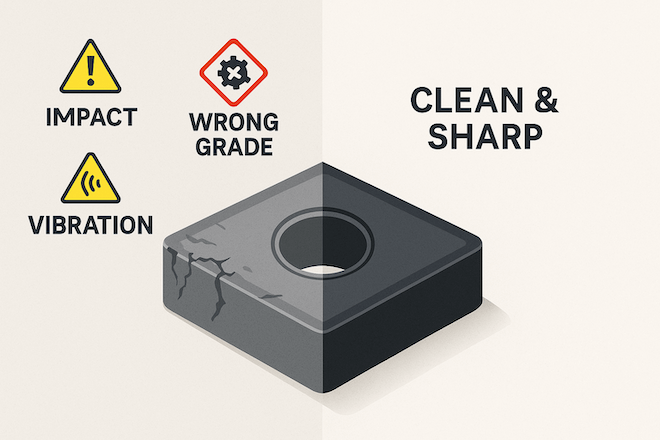

2. Astillado o rotura de bordes

🛠 Problema:

El filo de su herramienta de carburo puede astillarse o romperse repentinamente, especialmente al mecanizar materiales duros o resistentes.

✅ Solución:

Utilice el grado de carburo correcto. Los grados más duros son frágiles, mientras que los más tenaces resisten el astillamiento.

Evite cortes interrumpidos o fuerzas de impacto.

Utilice herramientas de carburo con filo reforzado o geometría especial.

Asegúrese de que la herramienta esté firmemente sujeta en la máquina para reducir la vibración.

¿Necesita ayuda para elegir la herramienta adecuada?

👉 Herramientas de corte de carburo personalizadas

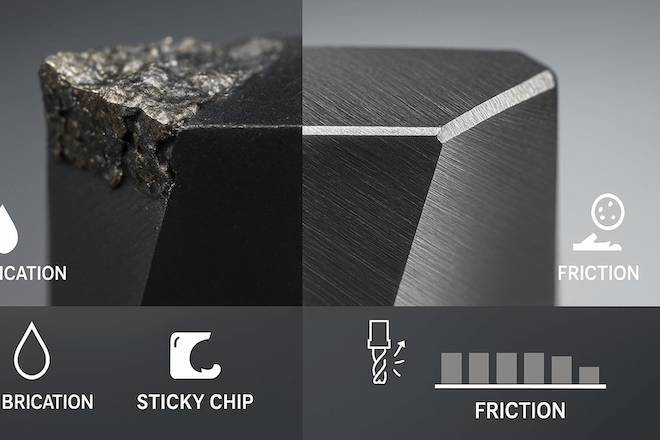

3. Borde acumulado en la punta de la herramienta

🛠 Problema:

El material puede adherirse al filo durante el mecanizado, formando un resalte. Esto reduce la precisión del corte y daña la herramienta.

✅ Solución:

Utilice herramientas de carburo recubiertas (como TiAlN o TiCN) para reducir la fricción.

Aumente ligeramente la velocidad de corte para evitar la acumulación.

Aplicar refrigerante o lubricación en la zona de corte.

¿Quieres saber más sobre recubrimientos?

👉 Guía de recubrimiento de carburo de tungsteno

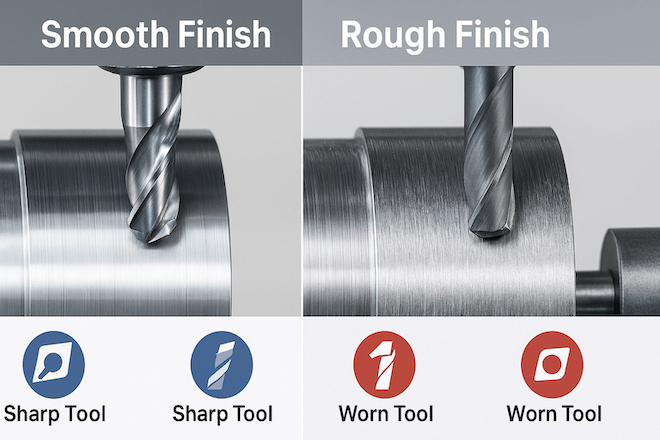

4. Mal acabado de la superficie

🛠 Problema:

La pieza terminada puede presentar rayones, asperezas o formas irregulares.

✅ Solución:

Compruebe si su herramienta está desafilada o dañada.

Utilice la geometría de herramienta de corte adecuada para su material.

Reduzca la vibración de la herramienta mejorando la configuración y la sujeción.

Intente utilizar un carburo de mayor calidad o reafilar la herramienta.

Para obtener consejos de mantenimiento, visite:

👉 Consejos de mantenimiento para prolongar la vida útil de sus herramientas de corte de carburo de tungsteno

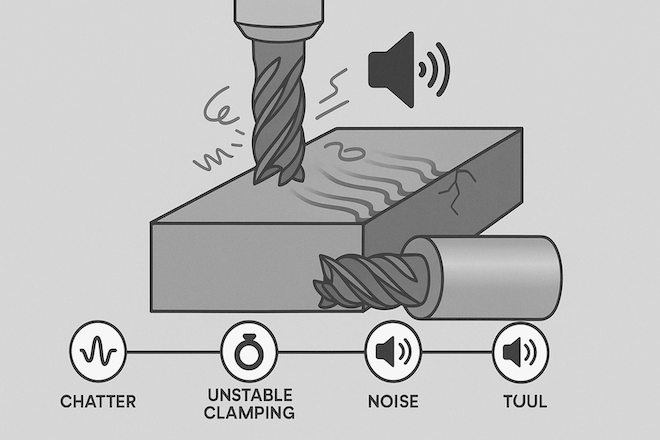

5. Vibración o traqueteo

🛠 Problema:

Las herramientas pueden vibrar o dejar marcas de vibración en la pieza. Esto reduce la precisión y puede dañar el filo.

✅ Solución:

Asegúrese de que la herramienta esté sujeta correctamente en un soporte rígido.

Utilice una extensión de herramienta más corta para reducir la desviación.

Disminuya la velocidad de corte o aumente ligeramente la velocidad de avance.

Utilice soportes amortiguados o herramientas equilibradas en aplicaciones de alta velocidad.

¿Buscas herramientas de corte más estables?

👉 Herramientas de corte de carburo de tungsteno

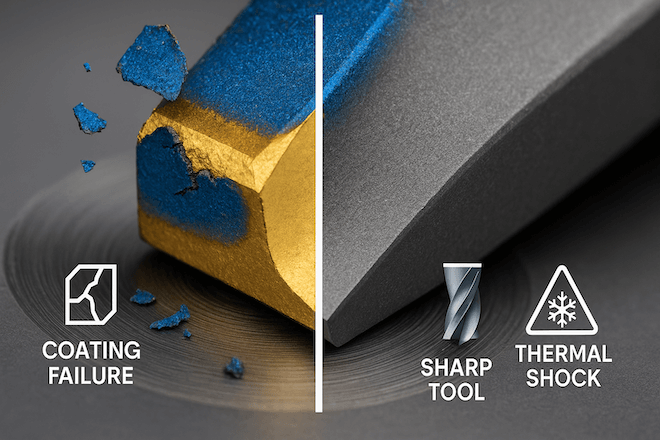

6. Pelado o descascarillado del revestimiento

🛠 Problema:

El revestimiento de su herramienta de carburo comienza a pelarse o desprenderse, dejando el material base expuesto.

✅ Solución:

Evite utilizar herramientas recubiertas en cortes de alto impacto si no están diseñadas para ello.

Elija el tipo de recubrimiento adecuado para su material y proceso.

Utilice refrigerante para evitar el choque térmico que debilita los recubrimientos.

¿Necesita servicios de recubrimiento o nuevas herramientas recubiertas?

👉 Contacto Retop para soluciones personalizadas.

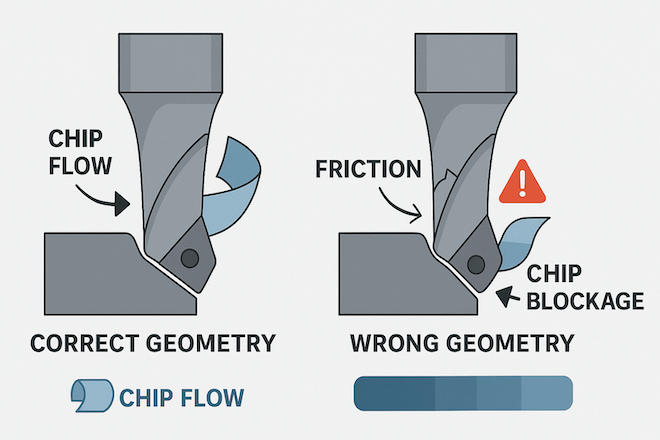

7. Geometría incorrecta de la herramienta

🛠 Problema:

A veces, la geometría de la herramienta de corte no es la adecuada para el material o la máquina. Esto provoca:

Mala acción de corte

Reducción de la vida útil de la herramienta

Tamaño de pieza inconsistente

✅ Solución:

Utilice herramientas diseñadas para su aplicación específica (por ejemplo, aluminio, acero inoxidable, etc.).

Para trabajos difíciles, solicite herramientas de carburo personalizadas que se adapten a su proceso.

Obtenga asesoramiento experto de un proveedor confiable de herramientas de carburo como Retop.

Explorar más opciones:

👉 Soluciones de insertos y herramientas de carburo

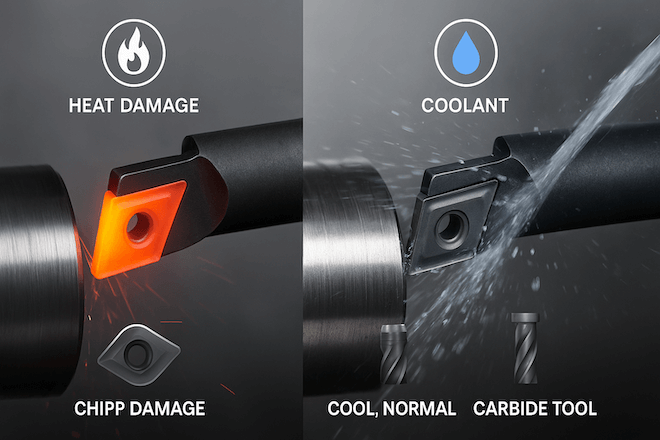

8. Sobrecalentamiento

🛠 Problema:

Si su herramienta se calienta demasiado durante el corte, puede perder dureza o desarrollar grietas térmicas.

✅ Solución:

Aplique abundante refrigerante o lubricante durante el corte.

Reduzca la velocidad de corte si es necesario.

Asegúrese de que la configuración de su máquina esté estable y alineada.

Conozca los recubrimientos de herramientas que ayudan a resistir el calor:

👉 Guía de recubrimiento de carburo de tungsteno

9. La herramienta no dura como se esperaba

🛠 Problema:

Usted espera que su herramienta de corte de carburo dure más, pero se desgasta rápidamente.

✅ Solución:

Comprueba que estás utilizando el correcto grado de carburo.

Considere utilizar herramientas recubiertas para lograr una vida útil más prolongada.

Utilice velocidades, avances y configuraciones correctos.

Afila tu herramienta antes de que esté demasiado desgastada.

¿Necesita ayuda para remodelar las herramientas?

👉 Cómo afilar y reacondicionar herramientas de corte de carburo de tungsteno

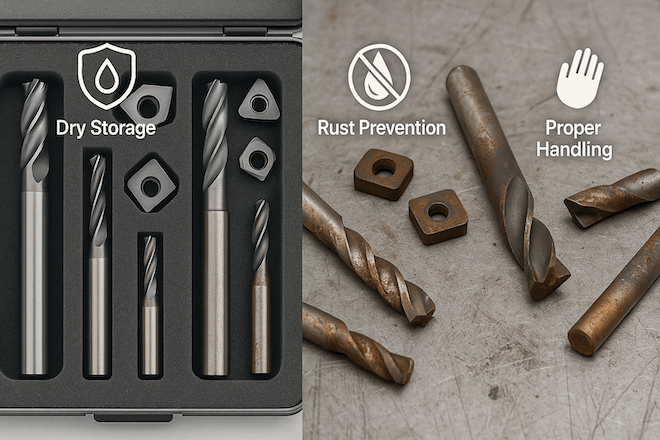

10. Daños durante el almacenamiento de herramientas

🛠 Problema:

Las herramientas de carburo almacenadas de forma incorrecta pueden dañarse, astillarse u oxidarse incluso antes de utilizarlas.

✅ Solución:

Guarde las herramientas en cajas o estantes revestidos con espuma.

Mantenlos secos y limpios.

Etiquete las herramientas para evitar confusiones.

Evite el contacto entre herramientas.

Proteja su inversión con un mejor manejo y almacenamiento. Retop también ofrece soluciones de embalaje para envíos de larga distancia.

Tabla resumen: problemas y soluciones

| Problema | Solución |

|---|---|

| Desgaste rápido | Verifique la velocidad/avance, use refrigerante, aplique el recubrimiento |

| Astillado de bordes | Utilice un grado más resistente y una configuración estable |

| Borde construido | Utilice recubrimiento, aumente la velocidad, utilice lubricante. |

| Mal acabado superficial | Afilar la herramienta, comprobar la geometría, reducir la vibración |

| Vibración / Vibración | Mejorar la sujeción, utilizar soportes rígidos |

| Pelado del revestimiento | Elija el recubrimiento correcto, evite el choque térmico |

| Geometría de herramienta incorrecta | Adapte la herramienta al material y pruebe herramientas personalizadas |

| Calentamiento excesivo | Utilice refrigerante, reduzca la velocidad, verifique la configuración |

| Vida útil corta de la herramienta | Utilice el grado de carburo correcto y afile antes de que falle. |

| Daños durante el almacenamiento de herramientas | Utilice un almacenamiento seco y acolchado y manipúlelo con cuidado. |

Reflexiones finales

Toda herramienta de corte de carburo de tungsteno puede ofrecer un mejor rendimiento y una mayor duración si se aplican las soluciones adecuadas. Pequeños cambios en la configuración, la velocidad de corte, el uso de refrigerante o el almacenamiento pueden marcar una gran diferencia.

Trabajar con un proveedor experimentado como Retop le ayuda a elegir las herramientas adecuadas y a evitar errores comunes. Ofrecemos una gama completa de soluciones de carburo, desde herramientas estándar hasta diseño personalizado de herramientas de carburo, recubrimientos, afilado y soporte.