Herramientas de corte de carburo de tungsteno Son conocidos por su resistencia, larga vida útil y capacidad para mecanizar materiales duros.

Pero un factor que a menudo se pasa por alto es la geometría: la forma y el ángulo del filo de la herramienta.

Elegir la geometría correcta para su aplicación puede marcar una gran diferencia en la velocidad de mecanizado, el acabado de la superficie, el control de viruta y el desgaste de la herramienta.

En este artículo, compararemos diferentes tipos de geometrías de herramientas de corte de carburo de tungsteno.

Aprenderá cómo funciona cada geometría, dónde se utiliza mejor y qué debe tener en cuenta al seleccionar una.

Ya sea que esté cortando acero, aluminio, compuestos o titanio, comprender la geometría de la herramienta lo ayudará a aprovechar al máximo su inversión.

¿Qué es la geometría de la herramienta?

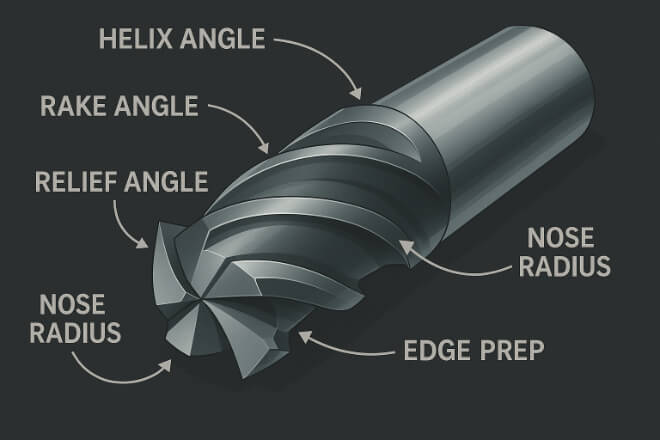

La geometría de la herramienta se refiere a los ángulos, bordes y formas integrados en una herramienta de corte.

Estas características controlan la interacción de la herramienta con la pieza. Los elementos geométricos comunes incluyen:

Ángulo de inclinación (positivo, neutro o negativo)

Ángulo de alivio (o ángulo de espacio libre)

Ángulo de hélice (espiral de la flauta)

Radio de la nariz

Chaflanes o preparación de bordes

Pequeños cambios en estas características pueden afectar en gran medida el flujo de viruta, la acumulación de calor, la resistencia de la herramienta y la calidad de la pieza final.

Por qué es importante la geometría en el mecanizado

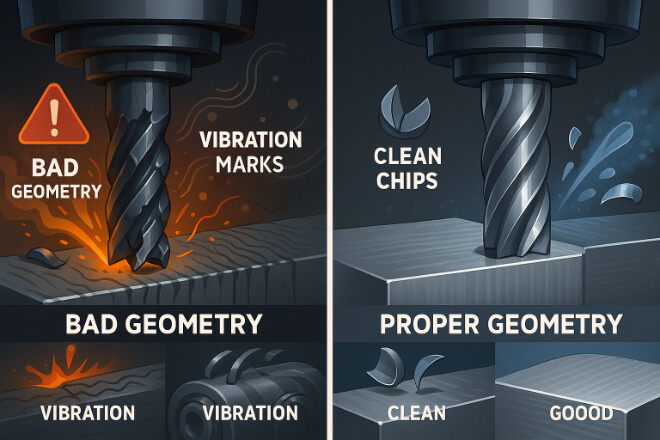

La geometría de la herramienta no es universal. Los distintos materiales y operaciones (como desbaste y acabado) requieren formas y ángulos diferentes. Elegir una geometría incorrecta puede provocar:

Desgaste excesivo de las herramientas

Mal acabado superficial

Borde construido (BUE)

Vibración o parloteo

Velocidad de corte reducida

Por otro lado, la geometría correcta mejora la evacuación de viruta, reduce las fuerzas de corte y permite una mayor vida útil de la herramienta, incluso a velocidades más altas.

Ángulos de inclinación positivos y negativos

| Tipo de rastrillo | Descripción | Mejor para | Beneficios |

|---|---|---|---|

| Rake positivo | El filo se inclina hacia adelante, hacia el material. | Aluminio, plásticos, metales blandos. | Menos fuerza de corte, mejor flujo de viruta |

| Rake negativo | El filo se aleja del material | Aceros endurecidos, fundición | Borde más fuerte, mayor resistencia al desgaste. |

Los ángulos de inclinación positivos cortan más suavemente y reducen el consumo de energía, pero pueden astillarse más fácilmente.

Los ángulos de inclinación negativos son más resistentes y duraderos, pero generan más calor.

Ángulos de hélice

El ángulo de hélice es el ángulo espiral de la flauta de una herramienta. Afecta la evacuación de viruta y la presión de corte.

| Ángulo de hélice | Ideal para | Beneficios |

|---|---|---|

| Baja (15–30°) | Materiales duros, cortes de desbaste | Borde más fuerte, menor desviación |

| Alta (35–45°) | Aluminio, materiales blandos | Mejor eliminación de virutas, acabado más suave |

Un ángulo de hélice más alto mejora el acabado superficial y el control de viruta en materiales más blandos. Una hélice más baja ofrece mayor resistencia y estabilidad al cortar materiales duros.

Preparación del radio y el borde de la nariz

El radio de la punta es la punta redondeada de una herramienta. Un radio pequeño es más afilado, mientras que un radio grande es más resistente y duradero.

| Radio de la nariz | Mejor para | Ventajas | Contras |

|---|---|---|---|

| Pequeño (0,2 mm) | Acabados, trabajos de detalle | Cortes afilados, superficie fina. | Puede desgastarse o astillarse más rápido |

| Grande (0,8 mm+) | Desbaste, cortes pesados | Punta más fuerte, menos astillado | Se necesita más fuerza de corte |

La preparación del borde (como biselar o afilar el filo) también puede reducir el microastillado y prolongar la vida útil de la herramienta.

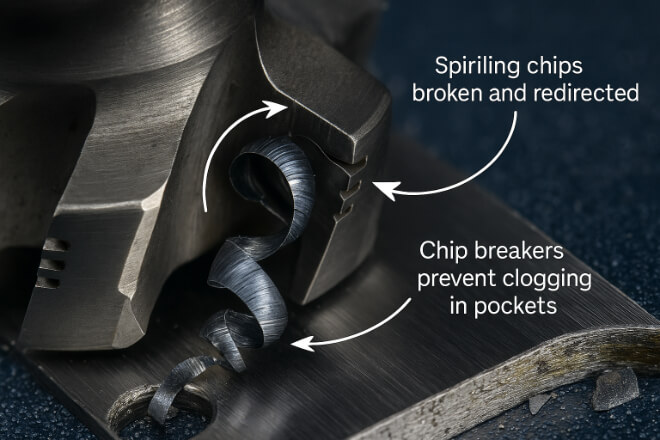

Rompevirutas

Los rompevirutas son pequeñas ranuras o formas cortadas en la cara de ataque de la herramienta. Su función principal es controlar el tamaño y la forma de la viruta.

Ayuda a evitar que se formen virutas largas y fibrosas

Reduce el calor y el desgaste de las herramientas.

Mejora la evacuación de virutas en cavidades y espacios reducidos.

El uso de rompevirutas es esencial al mecanizar materiales dúctiles como el aluminio o el cobre. Sin ellos, las virutas pueden enrollarse alrededor de la herramienta o la pieza, causando daños.

Geometría para acabado vs. desbaste

La geometría de la herramienta también varía según la operación:

| Operación | Enfoque en la geometría |

|---|---|

| Desbaste | Borde más fuerte, radio más grande, hélice más baja |

| Refinamiento | Borde más afilado, hélice más alta, radio de punta más pequeño |

Las herramientas de desbaste eliminan material rápidamente y requieren resistencia. Las herramientas de acabado requieren precisión y una superficie limpia.

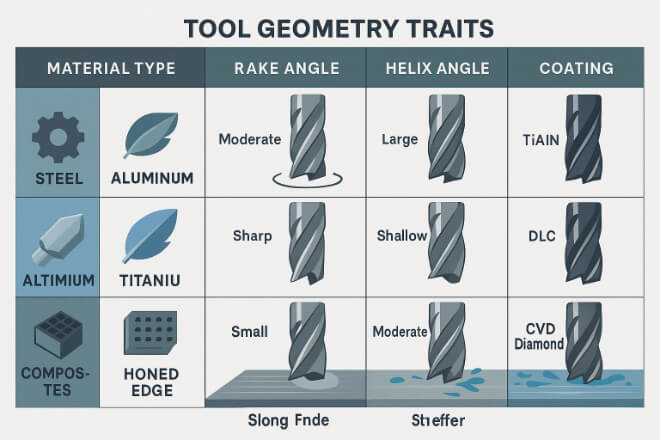

Geometría basada en el tipo de material

Cada material requiere características de herramienta diferentes para un buen mecanizado. Aquí tienes una guía rápida:

1) Acero

Rake negativo o rastrillo neutral

Ángulo de hélice moderado (30°)

Se prefiere carburo revestido

2) Aluminio

Rake positivo

Ángulo de hélice alto (40–45°)

Bordes afilados y flautas pulidas

3) Titanio

Alto rastrillo y hélice baja

Radio de nariz pequeño

Recubrimientos especiales (TiAlN)

4) Materiales compuestos

Herramientas recubiertas de diamante

Bordes muy afilados

Preparación mínima de los bordes

La adaptación de la geometría al material evita el desgaste, el astillado y el sobrecalentamiento.

Geometría personalizada y aplicaciones especiales

A veces, la geometría estándar no es suficiente. Los talleres que manejan materiales o piezas inusuales pueden necesitar:

Diámetros de herramientas personalizados

Longitudes especiales de flauta

Ángulos de alivio modificados

Recubrimientos únicos

Asociarse con un proveedor de carburo confiable le permite ajustar sus herramientas para obtener el máximo rendimiento.

Beneficios reales de la geometría correcta

Elegir la geometría correcta no es solo una cuestión de teoría: ofrece beneficios reales:

| Beneficio | Resultado para tu tienda |

|---|---|

| Mejor control del chip | Menos paradas de la máquina |

| Mayor vida útil de la herramienta | Cambios de herramientas menos frecuentes |

| Acabado de la pieza mejorado | Se necesita menos retrabajo o pulido |

| Mayor velocidad de corte | Tiempos de ciclo más cortos, mayor producción |

| Bajar la presión de la herramienta | Menos desgaste de la máquina, más estabilidad |

Estos beneficios son especialmente importantes en industrias como la aeroespacial, la automotriz, la fabricación de moldes y la fabricación médica.

Consejos finales para elegir la geometría de la herramienta

Adapte siempre la geometría de la herramienta al material y a las condiciones de corte.

Utilice las recomendaciones del fabricante como punto de partida.

No tengas miedo de probar pequeños cambios en el ángulo o el radio.

Monitoree el desgaste de la herramienta y la calidad de las piezas para detectar signos tempranos de desajuste geométrico.

Conclusión

Las herramientas de carburo de tungsteno son tan buenas como su geometría. Los ángulos, filos y preparación adecuados pueden influir significativamente en el éxito del mecanizado.

Ya sea que esté desbaste, terminando o trabajando con materiales difíciles, elegir la forma de herramienta correcta es importante.

Si necesita ayuda para seleccionar las mejores herramientas de carburo para su trabajo, explore la gama completa en Retopz.