En las industrias donde las piezas deben sobrevivir al desgaste, el calor y la corrosión, elegir el material adecuado es fundamental.

Tres de los materiales más populares para piezas de desgaste Son el carburo de tungsteno, la cerámica y la estelita. Cada material tiene propiedades, fortalezas y debilidades únicas.

Para los tomadores de decisiones en el sector manufacturero, minería, petróleo y gas, y otras industrias pesadas, la elección entre estos materiales puede afectar en gran medida los costos de producción, el tiempo de inactividad y el rendimiento del producto.

Esta guía compara piezas de desgaste de carburo de tungsteno, cerámica y estelita en detalle para que pueda tomar decisiones informadas para sus operaciones.

¿Qué es el carburo de tungsteno?

El carburo de tungsteno es un compuesto formado por átomos de tungsteno y carbono.

Es uno de los materiales más duros utilizados en la industria, con una dureza de entre 8,5 y 9 en la escala de Mohs.

Propiedades clave:

Extremadamente alto dureza — más duro que el acero y la mayoría de los metales.

Excelente resistencia al desgaste — Ideal para condiciones abrasivas.

Alta resistencia al calor: conserva la dureza incluso a altas temperaturas.

Moderado tenacidad — más frágil que el acero pero más fuerte que la mayoría de las cerámicas.

Aplicaciones comunes: Herramientas de corte, taladros de minería, matrices resistentes al desgaste, componentes de bombas y válvulas y boquillas.

¿Qué son las piezas de desgaste cerámicas?

Las cerámicas son materiales inorgánicos no metálicos fabricados a partir de compuestos como alúmina, zirconio o nitruro de silicio.

Propiedades clave:

Muy alto dureza — puede ser tan duro o más duro que el carburo de tungsteno.

Excelente resistencia a la corrosión: no se oxida ni se oxida.

Ligero: menos denso que las piezas de desgaste a base de metal.

Bajo tenacidad — muy frágil, propenso a agrietarse por el impacto.

Aplicaciones comunes: Cojinetes, sellos, hojas de corte para acabados muy finos y componentes de alta temperatura en procesos químicos.

¿Qué es la estelita?

La estelita es una aleación a base de cobalto que contiene cromo, tungsteno y otros metales.

Fue diseñado para una resistencia excepcional al desgaste y a la corrosión, especialmente a altas temperaturas.

Propiedades clave:

Alto resistencia al desgaste — especialmente en condiciones de deslizamiento y desgaste.

Buena resistencia a la corrosión, adecuado para entornos químicos y marinos.

Alto tenacidad — resiste el impacto mejor que el carburo de tungsteno y la cerámica.

Más bajo dureza que el carburo de tungsteno, pero a menudo es suficiente para muchos usos industriales.

Aplicaciones comunes: Asientos de válvulas, bordes de corte, álabes de turbinas y recubrimientos resistentes al desgaste.

Tabla de comparación de propiedades de los materiales

A continuación se muestra una comparación de los tres materiales:

| Propiedad | Carburo de tungsteno | Cerámico | Estelita |

|---|---|---|---|

| Dureza | 8,5–9 Mohs | 8–9,5 en la escala de Mohs | 4–6 escalas de Mohs |

| Resistencia al desgaste | Excelente | Excelente | Bien |

| Resistencia al calor | Muy alto | Muy alto | Alto |

| Resistencia a la corrosión | Alto | Excelente | Alto |

| Tenacidad | Moderado | Bajo | Alto |

| Densidad | Muy alto | Bajo a medio | Medio |

| Costo | Alto | Alto | Medio a alto |

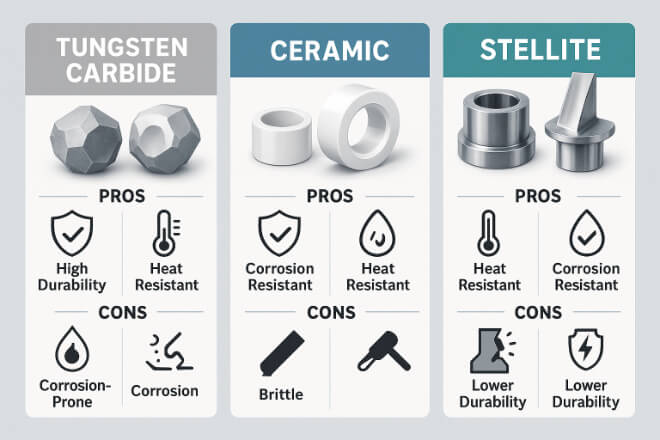

Fortalezas y debilidades de cada material

1) Carburo de tungsteno

1.1) Ventajas:

Excelente resistencia al desgaste en ambientes abrasivos.

Funciona bien en aplicaciones de altas temperaturas.

La larga vida útil reduce el tiempo de inactividad.

1.2) Desventajas:

Puede astillarse o romperse bajo un impacto muy fuerte.

Más caro que muchos aceros.

2) Cerámica

2.1) Ventajas:

Extremadamente duro y resistente a la corrosión.

Ligero: ideal para aplicaciones donde el peso importa.

Puede funcionar en temperaturas extremadamente altas.

2.2) Desventajas:

Frágil: puede fracturarse fácilmente bajo cargas de impacto o flexión.

Puede resultar costoso para piezas grandes o complejas.

3) Estelita

3.1) Ventajas:

Excelente tenacidad — soporta bien los golpes y las vibraciones.

Buena resistencia al desgaste y a la corrosión.

Se puede soldar o recubrir sobre otras piezas.

3.2) Desventajas:

Menor dureza en comparación con el carburo de tungsteno y la cerámica.

Puede desgastarse más rápido en entornos abrasivos.

Mejor material por tipo de aplicación

| Solicitud | La mejor opción | Razón |

|---|---|---|

| Minería y perforación | Carburo de tungsteno | Excepcional resistencia al desgaste en rocas y suelos abrasivos. |

| Procesamiento químico | Cerámico | Resistencia superior a la corrosión y capacidad de alto calor. |

| Asientos de válvulas en petróleo y gas | Estelita | Alta tenacidad para resistir impactos y vibraciones. |

| Herramientas de corte de alta velocidad | Carburo de tungsteno | Mantiene la nitidez y dureza a altas velocidades. |

| Cojinetes de alta temperatura | Cerámico | Ligero y estable bajo calor extremo. |

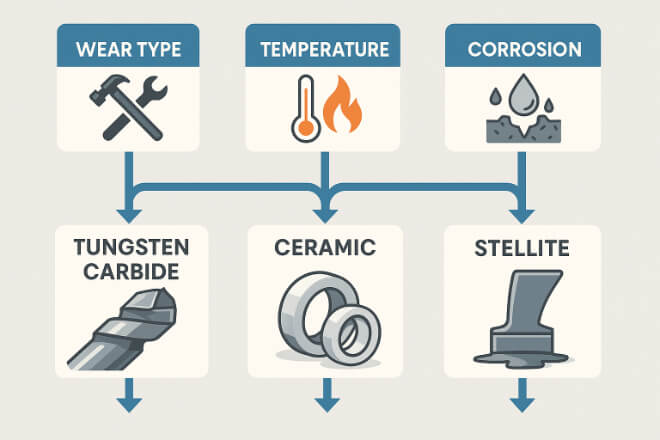

Elegir el material adecuado

Al decidir entre carburo de tungsteno, cerámica y estelita, tenga en cuenta lo siguiente:

Tipo de desgaste: Para la abrasión, el carburo de tungsteno y la cerámica son las mejores opciones. Para el impacto y el desgaste por rozamiento, la estelita es mejor.

Temperatura de funcionamiento: Los tres manejan bien el calor, pero la cerámica se destaca en calor extremo.

Riesgo de corrosión: La cerámica ofrece la mejor protección contra la corrosión, seguida de la estelita y el carburo de tungsteno.

Presupuesto: La estelita a menudo cuesta menos que la cerámica y el carburo de tungsteno para tamaños de piezas similares.

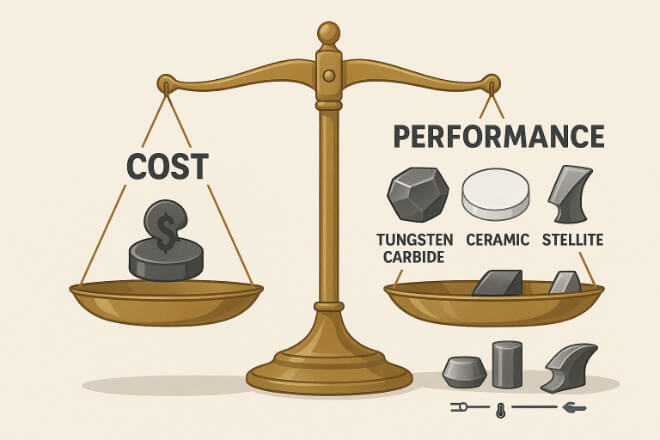

Costo vs. Rendimiento

Si bien la cerámica y el carburo de tungsteno pueden durar más, la estelita puede ser más rentable para ciertos trabajos.

Calcule siempre el coste total de propiedad, no solo el precio de compra. Factores como el tiempo de inactividad, los intervalos de sustitución y los costes de mecanizado son importantes.

Conclusión

El carburo de tungsteno, la cerámica y la estelita son excelentes materiales antidesgaste, pero se destacan en diferentes aspectos.

Elija carburo de tungsteno para una resistencia extrema a la abrasión y al calor.

Elija cerámica para aplicaciones ligeras y a prueba de corrosión.

Elija Stellite cuando la dureza y la resistencia al impacto son lo más importante.

Para los tomadores de decisiones, la elección correcta depende de su entorno operativo, su presupuesto y sus objetivos de rendimiento.

Una comparación cuidadosa de estos materiales puede ahorrarle dinero a su empresa y mejorar la confiabilidad del equipo.

Si desea conocer más detalles sobre alguna empresa, no dude en contactarnos. Contáctanos.