When engineers select bujes de carburo de tungsteno for pumps, compressors, or turbines, they often focus on dureza y resistencia al desgaste. But two equally critical parameters are dimensional tolerance and surface finish.

These two factors determine how well the bushing fits the shaft, how smoothly it operates, and how long it lasts. Even a small deviation — a few microns off — can cause excessive wear, vibration, or leakage.

This article explains what tolerances and surface finishes mean, how they affect bushing performance, and what specifications decision-makers should look for when sourcing from carbide suppliers.

What Are Dimensional Tolerances?

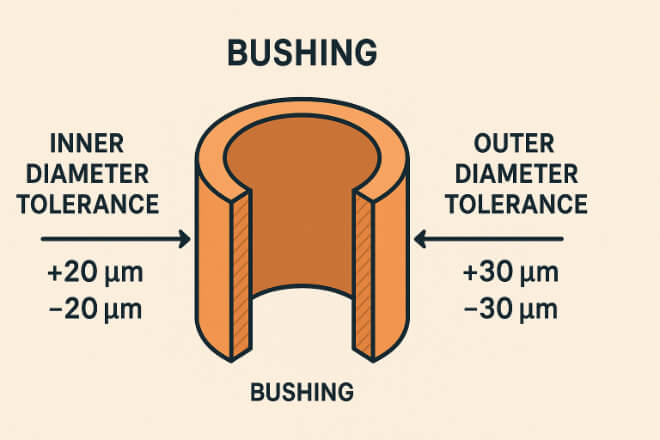

Tolerancia dimensional defines how much variation is allowed from a specified dimension during manufacturing.

For example, if a bushing’s inner diameter (ID) is 25.000 mm with a tolerance of ±0.005 mm, it means the actual size can range from 24.995 mm to 25.005 mm and still be acceptable.

In tungsten carbide bushings, tolerances are especially important because:

Carbide is extremely hard and brittle — difficult to machine after sintering.

Tight fits ensure stable alignment and minimal vibration.

Small errors can cause overheating or premature wear.

A quality bushing supplier uses CNC grinding, centerless polishing, and lapping machines to maintain precision down to microns.

Why Tight Tolerances Matter

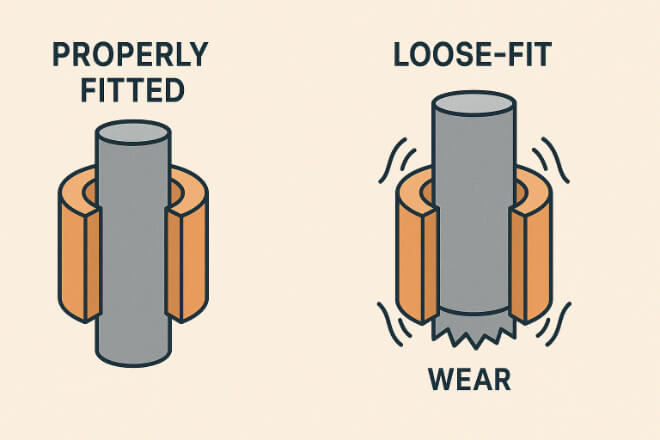

In rotating and high-pressure systems, tolerance accuracy ensures reliability and safety.

If the inner diameter (ID) is too tight, it may seize on the shaft during operation.

If it’s too loose, the shaft may vibrate, reducing efficiency and increasing leakage.

The correct balance ensures:

Consistent film thickness in lubricated systems

Stable alignment between moving parts

Reduced friction and heat generation

Longer service life for both bushing and shaft

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Common Tolerance Classes for Carbide Bushings

Carbide bushing tolerances are typically defined using ISO 286 or DIN standards.

The most common are H7, H6, and H5, depending on the fit requirement.

| Tolerance Class | Fit Type | Example Range (for Ø25 mm ID) | Solicitud |

|---|---|---|---|

| H7 | Standard fit | +0 / +0.021 mm | General pumps, compressors |

| H6 | Precision fit | +0 / +0.013 mm | High-speed shafts |

| H5 | Tight fit | +0 / +0.008 mm | Critical sealing or bearing positions |

High-end carbide manufacturers can achieve H5 or better through precision grinding and temperature-controlled production.

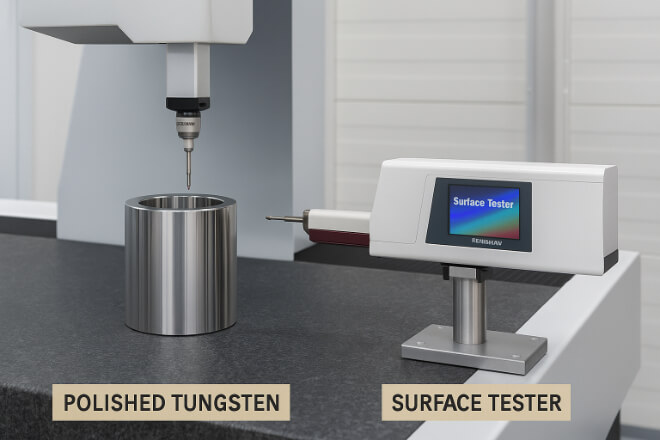

Understanding Surface Finish in Carbide Bushings

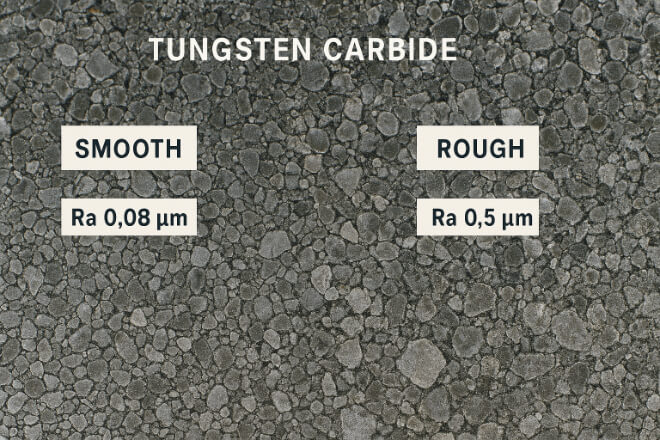

Surface finish describes how smooth or rough a surface is. It’s often measured in Ra (Roughness Average), expressed in micrometers (µm).

En bujes de carburo de tungsteno, a fine surface finish helps:

Reduce friction and wear

Maintain consistent lubrication film

Minimize leakage paths

Improve sealing performance

Typical surface finishes for carbide bushings range from Ra 0.1 µm to Ra 0.05 µm, depending on application and pairing material (such as steel or silicon carbide shafts).

Types of Surface Finishes

Different applications require different finishes. The choice depends on whether lubrication is present and how smooth the mating surfaces must be.

| Finish Type | Ra Range (µm) | Uso típico | Remarks |

|---|---|---|---|

| Ground | 0.20–0.10 | General purpose | Good balance of cost and performance |

| Lapped | 0.08–0.05 | High-speed or precision pumps | Excellent wear control and sealing |

| Mirror-Polished | ≤0.04 | Critical sealing faces | Reduces leakage and startup friction |

The smoother the finish, the more precise the contact — but polishing also increases cost and production time.

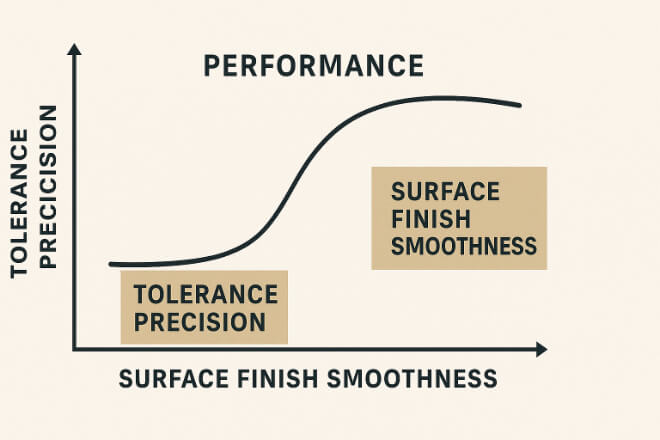

Tolerances vs. Surface Finish: How They Work Together

Tolerances and surface finish are interdependent.

A tight tolerance without a proper finish can cause galling or friction.

A smooth surface with poor tolerance can result in loose fits or shaft wobble.

For high-performance machines, both must be controlled together. The supplier’s machining precision, lapping quality, and inspection system are key to achieving this balance.

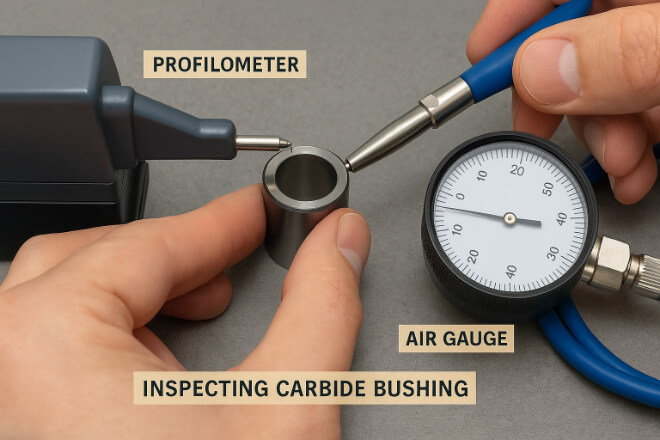

How Suppliers Measure and Control Precision

Reliable tungsten carbide suppliers follow a strict quality control process to ensure tolerances and surface finish meet design standards.

Typical steps include:

Precision grinding to rough dimension

Centerless finishing for uniform outer diameter

Lapping or polishing under controlled pressure

Surface inspection using a profilometer

Dimensional check with digital micrometers and air gauges

Flatness and concentricity check before packing

Suppliers also store measurement data to maintain batch traceability, ensuring every bushing meets its intended specification.

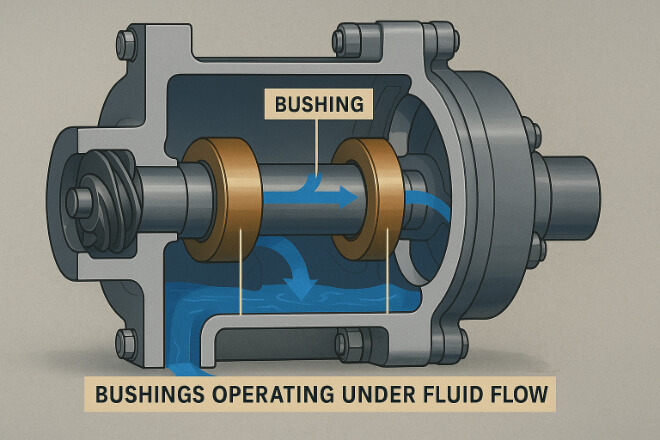

Applications Requiring Tight Tolerance and Fine Finish

Not all bushings require ultra-precision manufacturing.

However, industries with high rotational speeds or fluid sealing demand the best surface and tolerance control.

Typical examples include:

Oil and gas pump bushings (tight clearances under pressure)

Submersible pump sleeves (abrasive resistance)

Compressor guide bushings (vibration stability)

Cryogenic applications (thermal stability at low temperatures)

In these cases, H6 tolerance with Ra 0.05 µm finish is often standard.

Inspection Methods for Quality Assurance

Before shipping, each bushing should pass through dimensional and surface inspections.

The most common tools used include:

Digital micrometers and bore gauges

Máquinas de medición por coordenadas (CMM)

Surface roughness testers (Ra meters)

Roundness and concentricity instruments

A professional supplier also provides an inspection report with the following data:

ID and OD tolerance results

Surface roughness value (Ra)

Flatness or concentricity reading

Batch trace number

Conclusión

In tungsten carbide bushings, dimensional tolerance and surface finish are the two silent heroes behind smooth, efficient machine operation.

They directly impact how well the bushing fits, seals, and withstands load and temperature changes.

For decision-makers, the takeaway is simple:

Specify your required tolerance and finish clearly.

Work with certified suppliers who provide inspection reports and traceability.

Balance performance and cost — tighter tolerances and mirror finishes cost more but last longer.

Choosing precision today means fewer problems tomorrow.

Si desea conocer más detalles sobre alguna empresa, no dude en contactarnos. Contáctanos.