Industries like petróleo y gas, marine, chemical, and power generation are under pressure to reduce their environmental impact.

Every part of industrial equipment, including sealing systems, can influence sustainability. One material stands out for both performance and environmental benefits: anillos de sellado de carburo de tungsteno.

This article explains the environmental advantages of using tungsten carbide seal rings, showing how they help companies cut waste, save resources, and meet sustainability goals.

Why Seal Ring Materials Affect the Environment

Seal failures and frequent replacements create:

Waste → Broken or worn seals end up as scrap.

Energy loss → Leaks reduce equipment efficiency.

Higher emissions → Downtime or inefficiency leads to extra fuel use.

Resource consumption → More raw materials needed for replacements.

Choosing durable, recyclable materials like tungsten carbide can reduce these issues.

Propiedades clave de los anillos de sellado de carburo de tungsteno

Tungsten carbide is a compound of tungsten and carbon, often bonded with cobalt or nickel. Its properties offer environmental benefits:

Extremo dureza → Reduces wear, meaning fewer replacements.

Resistencia a la corrosión → Less waste from seals failing in chemicals or seawater.

Estabilidad térmica → Improves energy efficiency in high-temperature systems.

Reciclabilidad → Worn rings can be processed into new products.

Reduced Waste Through Longer Service Life

Because anillos de sellado de carburo de tungsteno resist wear and corrosion better than steel or ceramic alternatives, they:

Stay in service longer.

Need fewer replacements over a machine’s lifetime.

Reduce waste and disposal costs.

Fewer discarded seals means less material entering landfills.

Lower Energy Use and Emissions

Reliable seals prevent leaks in pumps, compressors, and turbines. Leaks waste energy by forcing equipment to work harder. With tungsten carbide seal rings:

Pumps maintain efficiency longer.

Compressors reduce fuel consumption.

Power systems avoid energy loss.

Better efficiency means lower greenhouse gas emissions.

Recyclability and Resource Recovery

Tungsten carbide can be collected and recycled:

Worn rings are ground down and reprocessed.

Recovered tungsten is reused for new products.

Recycling reduces demand for raw tungsten mining, which can be environmentally disruptive.

This circular approach supports sustainable manufacturing practices.

Applications Where Environmental Benefits Matter

Marine and offshore systems → Less waste and better protection against seawater corrosion.

Chemical processing plants → Fewer failures in corrosive fluids reduce environmental risks.

Mining and slurry handling → Long service life reduces downtime and scrap.

Power generation → Reliable seals improve energy efficiency in turbines and pumps.

Renewable energy equipment → Supports sustainable goals in wind, hydro, and solar systems.

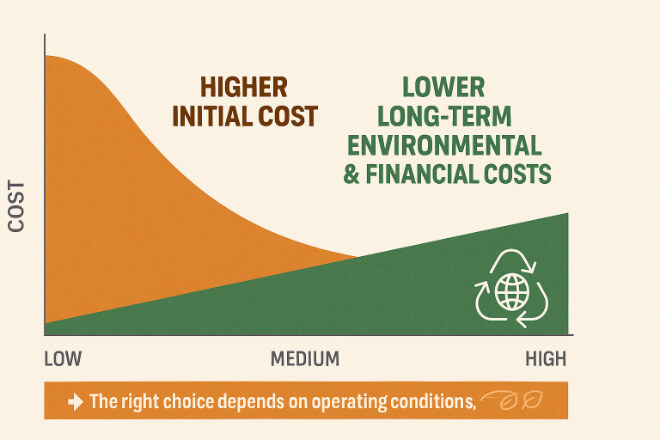

Cost vs Sustainability Value

While tungsten carbide seal rings may cost more upfront:

Fewer replacements save money on parts and labor.

Longer service life means less downtime.

Recycling reduces long-term environmental costs.

These benefits align with corporate sustainability strategies and environmental regulations.

Best Practices for Maximizing Environmental Impact

Seleccione la carpeta adecuada → Nickel-bonded for corrosive environments, cobalt-bonded for shock-heavy systems.

Use proper installation → Prevents leaks that waste energy.

Reciclar anillos desgastados → Partner with suppliers that offer tungsten recovery programs.

Perform regular inspections → Extends service life and prevents environmental incidents.

Conclusiones clave para los responsables de la toma de decisiones

Tungsten carbide seal rings offer clear environmental advantages: less waste, fewer emissions, and better efficiency.

Their durability and recyclability support sustainability goals in multiple industries.

Higher upfront cost is offset by long-term savings and reduced environmental impact.

Choosing tungsten carbide aligns with responsible resource use and corporate environmental strategies.

Conclusión

Switching to tungsten carbide seal rings is more than an engineering decision—it’s an environmental strategy. By lasting longer, reducing leaks, and being recyclable, these seal rings help industries lower waste and energy use.

For decision-makers, tungsten carbide represents a sustainable choice that balances performance, cost, and environmental responsibility.

Si desea conocer más detalles sobre alguna empresa, no dude en contactarnos. Contáctanos.