Tungsten carbide bushings are high-performance components used in demanding industries such as minería, pumps, and machinery.

These bushings offer excellent resistencia al desgaste, but they need to be properly protected during shipping to ensure they reach their destination without damage.

Two critical factors to consider when packaging tungsten carbide bushings for export are moisture and shock protection.

In this blog, we’ll explore best practices for packaging these bushings to prevent moisture-related damage and minimize the risk of shock during transportation, helping ensure the safe delivery of high-quality products.

Why Moisture and Shock Protection Matter for Tungsten Carbide Bushings

Tungsten carbide bushings are highly durable, but like any precision component, they are sensitive to environmental factors during transport.

Two of the most important considerations are moisture and shock, which can cause damage to the bushings before they even reach the customer. Here’s why these factors matter:

1). Moisture Protection

Moisture can cause several issues for tungsten carbide bushings during transportation:

Corrosion: Even though tungsten carbide is highly resistant to corrosion, the binder material (e.g., cobalt or nickel) can be more vulnerable to moisture, leading to degradation over time.

Rust Formation: If moisture is trapped inside packaging, it can cause rust formation on the surfaces of the bushings, which may affect their performance and integrity.

2). Shock Protection

Transportation involves handling, movement, and vibration, all of which can subject tungsten carbide bushings to shock. Shock or excessive impact can lead to:

Cracking: Tungsten carbide is extremely hard but brittle. If a bushing experiences high impact, it can crack or chip, which can reduce its effectiveness.

Surface Damage: Shock can also cause minor surface imperfections that may affect the bushing’s performance, such as rough edges or misalignment.

Therefore, taking proactive steps to protect against moisture and shock is crucial to maintaining the integrity of the bushings.

Best Practices for Moisture Protection in Packaging

To ensure that moisture doesn’t compromise the quality of your tungsten carbide bushings, it is important to implement moisture protection techniques in your packaging. Here are some effective methods:

1). Use Moisture-Resistant Packaging Materials

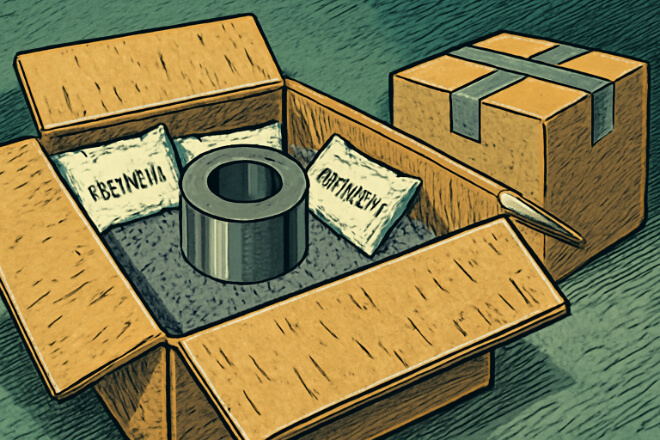

Vacuum Sealing: Vacuum sealing the bushings in moisture-proof plastic bags can help prevent exposure to moisture during transportation. This method also reduces the risk of contamination.

Desiccants: Adding desiccant packs (e.g., silica gel) inside the packaging can help absorb any moisture present in the packaging environment, ensuring the bushings stay dry.

Plastic Coatings: Wrapping the bushings in moisture-resistant plastic film can provide an additional layer of protection from humidity.

2). Choose Appropriate Packaging for Different Environments

Sealed Containers: For long shipments, using sealed containers with controlled humidity is ideal, especially when shipping to regions with high humidity or extreme weather conditions.

Air-Tight Boxes: Using air-tight, sealed boxes ensures that no moisture can penetrate the packaging during transport, reducing the risk of corrosion or rust.

3). Monitor Packaging Conditions

Humidity Monitoring: Incorporating humidity indicators in the packaging helps track moisture levels during transit, so you can monitor the conditions and take corrective action if needed.

Quality Control: Ensuring that the packaging is thoroughly checked before dispatch can help prevent any breaches or weaknesses in moisture protection.

Best Practices for Shock Protection in Packaging

Shock is an unavoidable risk during transportation, but with the right packaging, it can be minimized. Here are some best practices for protecting tungsten carbide bushings from shock:

1). Cushioning Materials

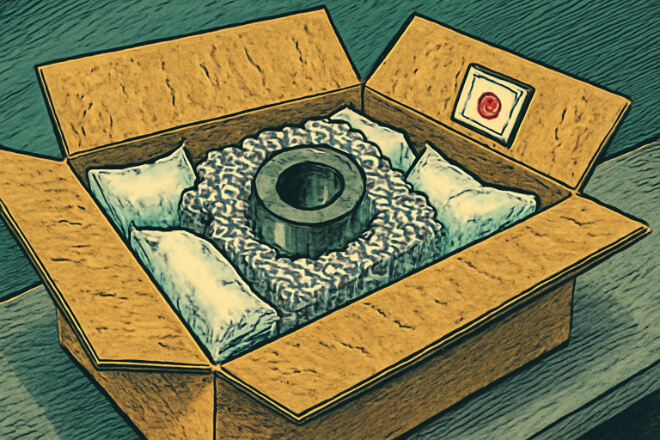

Foam Inserts: Using foam inserts within packaging boxes can absorb impact and prevent the bushings from being directly exposed to shocks.

Bubble Wrap: Wrapping the bushings in bubble wrap provides an additional layer of cushioning and reduces the risk of damage from sudden impacts.

Inflatable Packaging: Inflatable packaging or air pillows can create a protective barrier around the bushings, absorbing any shock and minimizing the chance of damage.

2). Proper Box Sizing

Fit the Packaging: Ensure that the packaging is the correct size for the bushings. Too much empty space in the box increases the risk of movement, which can lead to impact and damage. Ensure the bushings are snugly fit, with enough cushioning to absorb shock.

Reinforced Outer Packaging: Using double-walled or reinforced cardboard boxes adds strength to the packaging, ensuring it can withstand external pressure during transportation.

3). Shock Indicators

Shock Watch Indicators:

These devices can be placed inside the packaging to track and indicate if excessive shock or impact has occurred during transit. This helps monitor whether the bushings are subjected to damaging forces.

Packaging Materials to Avoid

While there are many options for protecting bujes de carburo de tungsteno, certain materials and methods should be avoided:

1). Non-Ventilated Packaging

Packaging that traps air and doesn’t allow for ventilation can lead to moisture buildup, which may affect the quality of the bushings. Always ensure proper ventilation or use moisture-proof materials.

2). Thin, Fragile Packaging

Using thin or cheap packaging materials that aren’t designed for heavy-duty transport can result in the bushings being damaged during transit. Always opt for durable, sturdy materials that are designed for industrial use.

3). Using Recycled Materials

While recycling is important, using recycled packaging materials that have not been adequately cleaned or treated can introduce contaminants that may negatively affect the tungsten carbide bushings.

Conclusión

Proper packaging is critical for ensuring that tungsten carbide bushings are protected from moisture and shock during transport.

By using moisture-resistant materials, cushioning, and proper packaging methods, you can prevent costly damage to the bushings, ensuring they arrive at their destination in excellent condition.

Whether you’re shipping locally or internationally, investing in the right packaging will safeguard your products and optimize the supply chain process.

Si desea conocer más detalles sobre alguna empresa, no dude en contactarnos. Contáctanos.