Flow cage and sleeve assemblies are essential components in many industrial applications, including pumps, compressors, and turbines. These assemblies ensure smooth operation by containing fluid flow, reducing friction, and supporting moving parts.

Tungsten carbide bushings are increasingly integrated into these assemblies due to their exceptional resistencia al desgaste, durability, and performance in harsh environments.

In this blog, we will explore how tungsten carbide bushings enhance flow cage and sleeve assemblies and why they are the ideal choice for demanding applications.

Understanding Flow Cage and Sleeve Assemblies

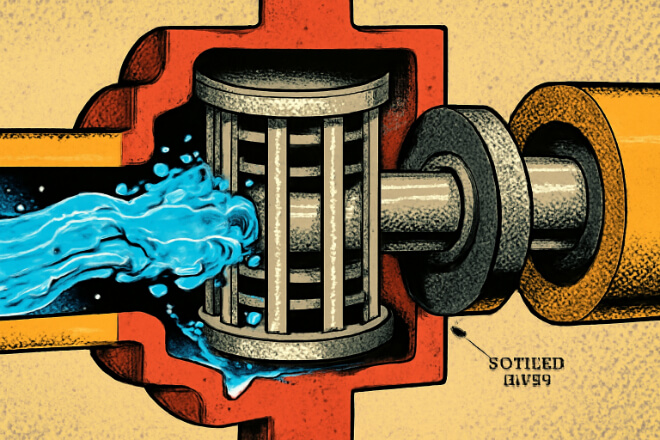

Flow cage and sleeve assemblies are used to contain, guide, and support rotating components in fluid systems.

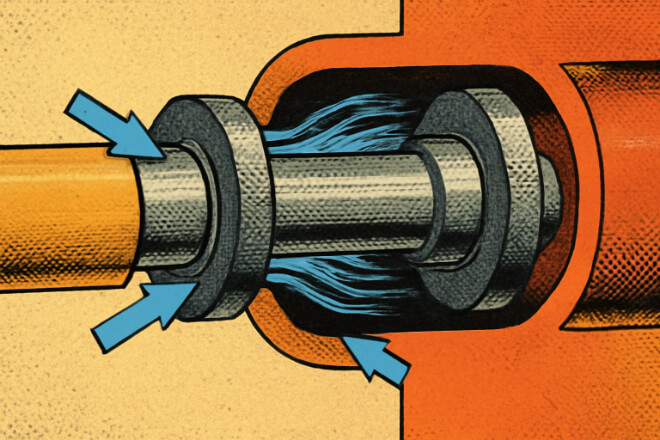

The sleeve typically acts as a housing for rotating shafts or other moving parts, while the cage holds the parts in place and guides the fluid flow.

Together, they ensure the smooth operation of pumps, compressors, and turbines by reducing friction and wear.

1). Function of the Flow Cage and Sleeve Assemblies

Containment: These assemblies help contain and direct the fluid flow in a controlled manner.

Support: They support rotating shafts or other parts within the system, ensuring proper alignment and reducing vibrations.

Friction Reduction: By reducing friction between moving parts, they prevent excessive wear and increase the longevity of components.

2). Importance in Fluid Systems

In many industrial systems, fluid flows are subject to high pressures, temperatures, and abrasive conditions.

The components that manage these flows must be able to withstand these harsh conditions without failing, making durable materials like tungsten carbide ideal for use in flow cage and sleeve assemblies.

Why Tungsten Carbide Bushings Are Ideal for Flow Cage and Sleeve Assemblies

Tungsten carbide bushings are increasingly used in flow cage and sleeve assemblies due to their unique properties. Here’s why they are the material of choice for these applications:

1). Exceptional Resistencia al desgaste

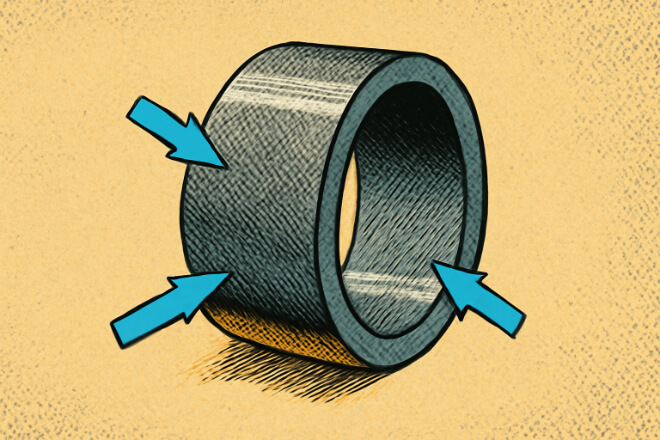

Tungsten carbide is one of the hardest materials available, making it resistant to wear from abrasive fluids or particles.

This makes tungsten carbide bushings ideal for applications where high wear resistance is needed, such as in flow cage and sleeve assemblies exposed to abrasive slurries or particles in the fluid.

2). High Durability and Long Life

Tungsten carbide bushings have a long service life, even under extreme operating conditions.

Their durability reduces the frequency of maintenance and replacement, ensuring that flow cage and sleeve assemblies remain operational for longer periods.

3). Low Friction

Tungsten carbide bushings have a smooth surface finish, which helps reduce friction between the rotating shaft and the sleeve.

This minimizes wear, heat generation, and energy loss, improving the overall efficiency of the system.

4). Resistencia a la corrosión

In many fluid systems, corrosive fluids can degrade traditional materials over time.

Tungsten carbide is highly resistant to corrosion, making it an ideal material for applications involving harsh chemicals, high-temperature fluids, or environments where other materials may corrode.

Benefits of Integrating Tungsten Carbide Bushings in Flow Cage and Sleeve Assemblies

By integrating tungsten carbide bushings into flow cage and sleeve assemblies, companies can experience several benefits that contribute to system performance, reliability, and cost-effectiveness:

1). Increased Efficiency

The reduced friction and wear enabled by tungsten carbide bushings improve the efficiency of the entire system.

With less energy lost to friction and reduced wear on other components, pumps, compressors, and turbines run more efficiently.

2). Reduced Downtime and Maintenance Costs

Tungsten carbide bushings increase the service life of flow cage and sleeve assemblies, reducing the need for frequent repairs or replacements.

This translates into less downtime for the equipment and lower maintenance costs over time.

3). Enhanced Reliability

By ensuring smooth and efficient operation in demanding conditions, tungsten carbide bushings enhance the overall reliability of the system.

This is particularly important for industries that rely on continuous operations, where unexpected failures can lead to costly interruptions.

Selecting the Right Tungsten Carbide Bushing for Your Application

When choosing tungsten carbide bushings for flow cage and sleeve assemblies, several factors must be considered to ensure optimal performance:

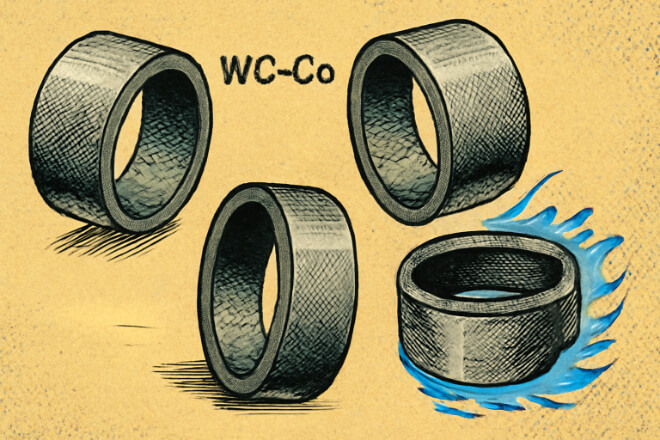

1). Material Composition

Tungsten carbide bushings can be made with various binders, such as cobalt (WC-Co) or nickel (WC-Ni).

The binder type affects the bushing’s tenacidad, dureza, y resistance to corrosion.

For fluid systems with corrosive liquids, WC-Ni bushings may be preferred for their superior corrosion resistance.

2). Size and Tolerance

Choosing the right size and tolerance is critical to ensure proper fit and function within the assembly.

Improperly sized bushings can lead to misalignment, increased wear, and reduced system efficiency.

3). Operational Conditions

Consider the operational conditions, including the temperature, pressure, and type of fluid.

Tungsten carbide bushings designed for high-temperature or high-pressure applications will have different specifications than those used in standard conditions.

Conclusión

Tungsten carbide bushings are an excellent choice for flow cage and sleeve assemblies in demanding fluid systems.

Their exceptional wear resistance, low friction, and long lifespan make them ideal for use in pumps, compressors, and turbines.

By integrating tungsten carbide bushings into these assemblies, companies can improve system efficiency, reduce downtime, and lower maintenance costs.

Properly selecting and integrating the right tungsten carbide bushings ensures that your fluid systems perform reliably and efficiently for longer periods, even in harsh operating conditions.

Si desea conocer más detalles sobre alguna empresa, no dude en contactarnos. Contáctanos.