The microstructure of bujes de carburo de tungsteno plays a key role in determining how well they perform under wear, heat, and pressure.

While many buyers focus on grade codes like YG6 or YG8, the real story lies inside — in the arrangement of carbide grains and binder metal.

For decision-makers in industries such as petróleo y gas, pumps, compressors, and precision machinery, understanding carbide microstructure helps make better sourcing and design decisions.

The right microstructure can mean longer service life, smoother operation, and lower total cost of ownership.

This article explains how microstructure is formed, what components it includes, and how it affects key properties like hardness, toughness, and corrosion resistance.

What Is Microstructure in Tungsten Carbide Bushings?

In simple terms, microstructure refers to how the materials inside tungsten carbide are arranged and bonded together.

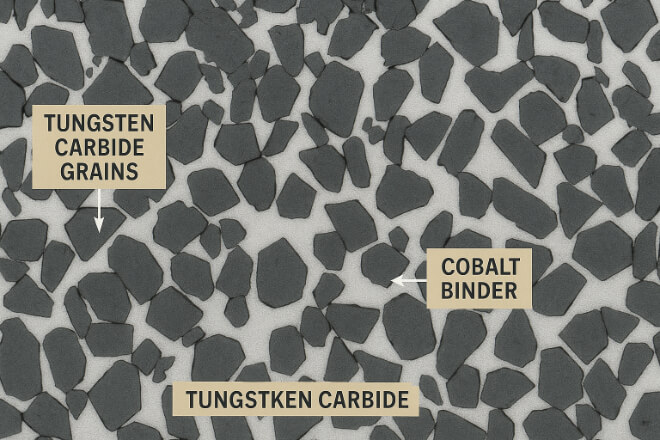

A typical tungsten carbide (WC) Bushing is not pure tungsten carbide — it is a composite made of:

Tungsten carbide grains (WC): Hard ceramic particles that give resistencia al desgaste.

Cobalt or Nickel binder (Co/Ni): A metal that holds the grains together, adding tenacidad.

The combination of these two creates a hardmetal structure — extremely hard, but still strong enough to handle shock and vibration.

Under a microscope, the microstructure looks like small gray crystals (WC) surrounded by lighter regions (binder).

The size, distribution, and bonding of these parts determine how the bushing behaves in real applications.

How Microstructure Is Formed

The microstructure of tungsten carbide is created during the powder metallurgy process, which includes mixing, pressing, and sintering.

| Stage | Process Description | Microstructure Effect |

|---|---|---|

| Mezcla de polvos | WC powder blended with Co/Ni binder and additives | Uniform distribution of grains and binder |

| Prensado | Powder compacted into shape under high pressure | Controls density and particle contact |

| Sinterización | Heated to 1350–1500°C to fuse particles | Final grain size, bonding, and porosity defined |

Each step influences the grain growth and binder distribution, and even small changes in sintering temperature or powder purity can drastically affect performance.

Key Microstructural Features That Influence Performance

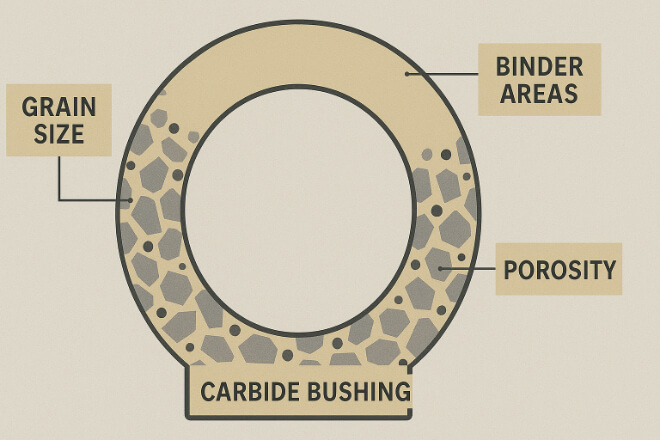

The main factors in tungsten carbide microstructure that affect bushing performance are:

Grain Size (Fine vs Coarse)

Binder Content (Cobalt or Nickel %)

Distribución de aglutinantes

Let’s look at each in detail.

1) Tamaño del grano

Grain size refers to the diameter of the WC particles. Smaller grains make the carbide harder, while larger grains improve toughness.

Fine-grained carbide (0.2–0.8 µm): Higher dureza y resistencia al desgaste

Coarse-grained carbide (1.5–5 µm): Better tenacidad and impact resistance

Micrograin or submicron carbides are ideal for applications where the bushing must resist abrasive wear and maintain tight tolerances.

2). Binder Content

The binder (Cobalt or Nickel) acts like glue that holds the hard grains together.

Its percentage — usually between 6% and 12% — controls the balance between hardness and toughness.

Lower binder (≤6%): High hardness, low ductility

Higher binder (10–12%): Better shock resistance, slightly less hardness

Cobalt binders are standard for general wear, while Nickel binders are preferred in corrosive environments such as chemical and marine applications.

Porosity means small air gaps left after sintering.

Too much porosity weakens the material and allows fluid infiltration, which accelerates corrosion and erosion.

High-quality bushings have density ≥ 14.5 g/cm³ and are nearly pore-free.

Suppliers measure this using ultrasonic testing and density checks, ensuring structural uniformity.

4). Binder Distribution

Uniform binder distribution prevents weak zones or cracks during load cycles.

A poor mix can cause uneven stress concentration or localized corrosion, especially in high-pressure pumps.

Advanced manufacturers use vacuum sintering to achieve even binder flow and better bonding between WC and metal phases.

Microstructure and Its Impact on Mechanical Properties

Each element of the microstructure affects the material’s hardness, strength, and corrosion behavior.

Here’s a simplified comparison:

| Microstructure Feature | Property Impact | Performance Result |

|---|---|---|

| Fine Grain | High hardness, low fracture toughness | Excelente resistencia al desgaste |

| Coarse Grain | Lower hardness, higher toughness | Better impact strength |

| High Binder Content | Increased toughness, reduced hardness | Suitable for vibration or shock loads |

| Low Porosity | Higher strength and corrosion resistance | Mayor vida útil |

By adjusting grain size and binder content, engineers can design bushings optimized for abrasion, corrosion, or impact resistance.

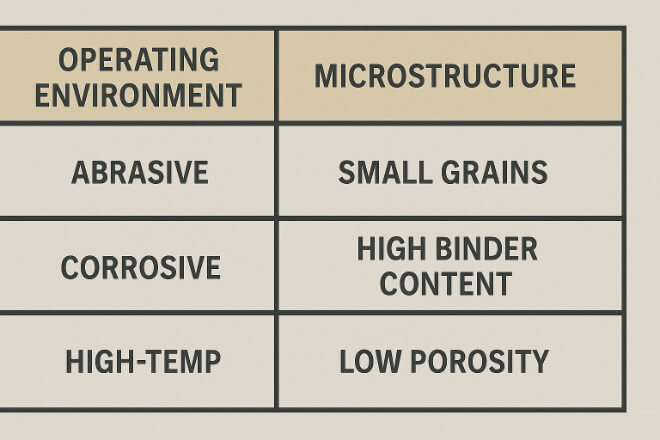

Choosing the Right Microstructure for Different Environments

Different operating conditions require different carbide microstructures.

Abrasive media (sand, slurry): Fine grain + low binder for resistencia al desgaste

Corrosive liquids (acids, seawater): Ni binder + dense microstructure

High vibration (pumps, compressors): Coarse grain + high binder for shock absorption

High temperature: Fine grain + stable binder composition

Selecting the correct combination ensures that the bushing resists both mechanical and chemical degradation over time.

Inspection and Verification of Microstructure

Before approving a batch of tungsten carbide bushings, quality suppliers use metallographic analysis to verify internal structure.

They perform:

Polishing and etching of samples

Microscope imaging (500x–1000x)

Grain size measurement

Porosidad classification (ISO 4505 standards)

These tests confirm whether the product meets the intended grade and consistency.

Buyers should request a microstructure report along with the dimensional inspection and hardness certificate. This ensures material integrity and process reliability.

Why Microstructure Matters for Decision-Makers

For procurement and engineering managers, understanding microstructure helps with:

Selecting the right grade for specific conditions

Evaluating supplier quality (consistent sintering = reliable parts)

Predicting wear life and replacement intervals

Reducing total lifecycle cost of critical components

A supplier who can control microstructure precisely will deliver better consistency, less downtime, and higher ROI.

Conclusión

The microstructure of tungsten carbide bushings determines how they perform under stress, temperature, and corrosion.

Grain size, binder type, porosity, and density all play vital roles.

For high-performance applications, it’s not just about hardness — it’s about achieving the right balance between strength and toughness through microstructural control.

By partnering with suppliers who understand carbide science and offer transparent inspection data, companies can ensure long-term reliability and efficiency.

Si desea conocer más detalles sobre alguna empresa, no dude en contactarnos. Contáctanos.