The oil and gas industry faces some of the harshest working conditions in the world. Drilling deep into the earth, cutting through rock, and maintaining production lines requires tools that are both strong and reliable. This is where tungsten carbide cutting tools stand out. Known for their exceptional hardness, wear resistance, and long tool life, these tools have become a key part of modern oil and gas operations.

In this blog, we’ll explore what makes tungsten carbide so effective, how it is used in the field, and why it continues to be the smart choice for companies working in demanding drilling and extraction environments.

¿Qué es el carburo de tungsteno?

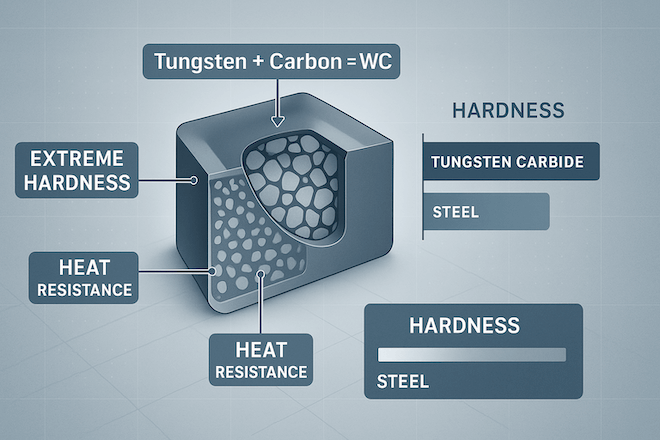

Tungsten carbide is a hard material made by combining tungsten and carbon. The result is a compound that is much harder than steel and can stay sharp even in tough conditions. Tungsten carbide is often used in tools that cut, drill, grind, or shape other materials.

It is popular in the Industria del petróleo y el gas because it can handle high-pressure, high-temperature, and high-wear environments without breaking or wearing out quickly.

Why Oil and Gas Operations Need High-Performance Tools

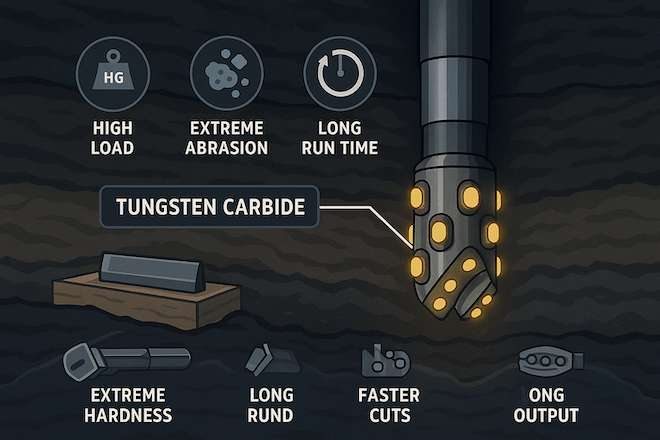

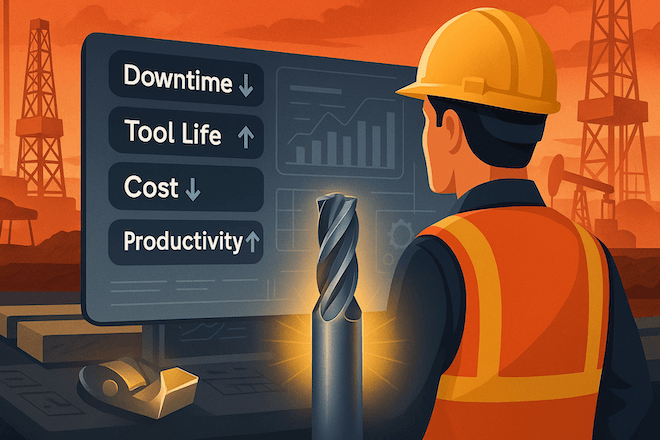

Drilling through rock, sand, and shale is extremely tough on tools. Traditional steel tools wear out fast, causing downtime and replacement costs. Herramientas de corte de carburo de tungsteno offer a better solution because they last longer and can keep working under extreme conditions.

This is especially important in downhole tools, drilling heads, and subsea components where tool failure can lead to expensive delays and lost production.

Common Tungsten Carbide Tools in Oil and Gas

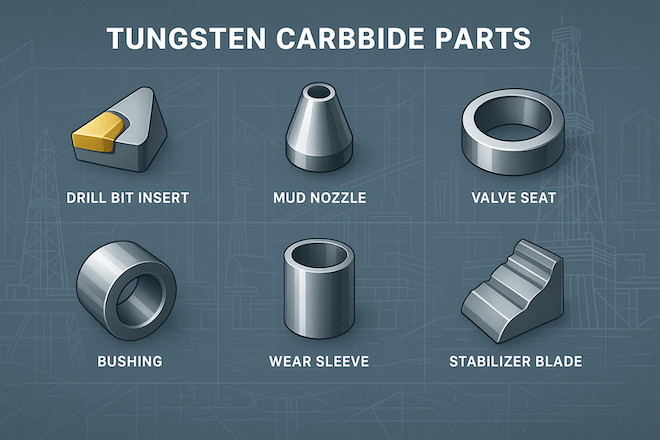

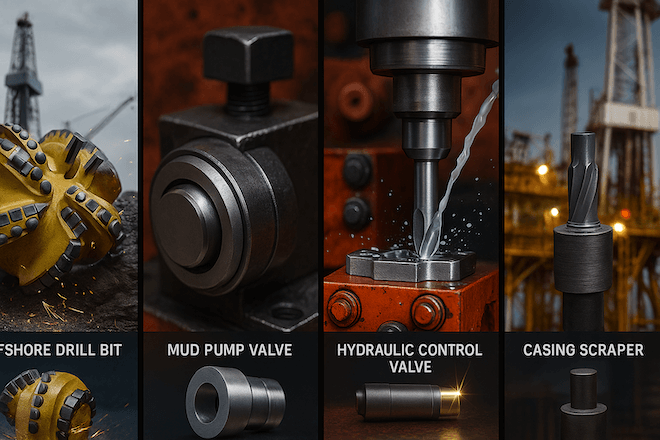

The oil and gas sector uses many types of herramientas de carburo de tungsteno, incluido:

Tungsten carbide inserts for drill bits

Wear-resistant nozzles for mud circulation

Valve parts in high-pressure pipelines

Scrapers and stabilizers with carbide hardfacing

These tools help improve drilling speed, reduce downtime, and cut maintenance costs.

Beneficios de utilizar herramientas de corte de carburo de tungsteno

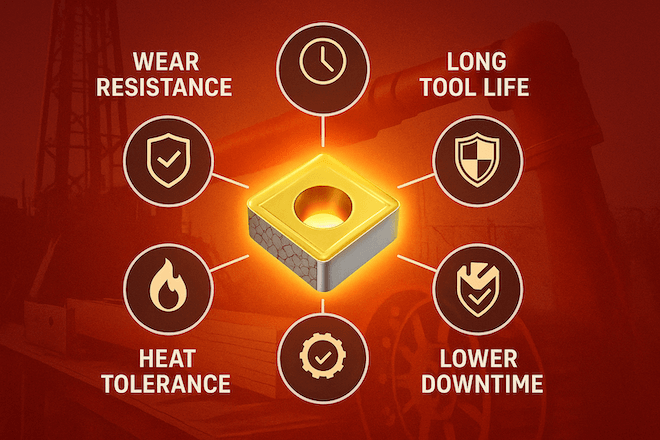

The oil and gas industry chooses tungsten carbide tools for many reasons:

Resistencia al desgaste: They last much longer than steel.

High Strength: They resist deformation under pressure.

Estabilidad térmica: They stay strong in high heat.

Precision: They hold their shape for accurate cutting.

Reduced Downtime: Fewer tool changes mean more working hours.

These benefits help reduce costs and improve productivity.

Applications in Oilfield Environments

Tungsten carbide tools are used in various parts of oil and gas production:

Drill bits in onshore and offshore rigs

Pump parts in hydraulic fracturing systems

Valves and chokes in high-pressure fluid control

Cutting heads for pipeline trenching

Casing scrapers in wellbore cleaning

Each application requires strength, accuracy, and long service life—qualities that tungsten carbide delivers.

Why Oil and Gas Decision Makers Choose Tungsten Carbide

For managers and engineers in the oil and gas sector, the goal is simple: keep operations running with as little downtime as possible. Tungsten carbide tools help meet this goal by reducing tool change frequency, improving cutting speed, and lowering replacement costs.

By choosing high-performance materials, decision-makers improve both efficiency and profitability.

Consejos para elegir la herramienta de carburo de tungsteno adecuada

To get the best results from tungsten carbide tools, oil and gas companies should:

Select the correct grado de carburo for each use

Usar herramientas de carburo revestidas for even longer life

Check tool geometry for material compatibility

Trabaje con proveedores experimentados

Monitor tool performance with sensors or data logs

Choosing the right tool from the start saves time and money.

Conclusión

The oil and gas industry depends on strong, precise, and long-lasting tools to meet today’s challenges. Tungsten carbide tools provide the performance needed to drill deeper, run longer, and produce more—while cutting costs and downtime. For decision-makers looking to upgrade tool performance, tungsten carbide remains the clear choice.

If you’re seeking high-performance tungsten carbide tools for your oil and gas operations, consider working with a trusted supplier like Retocar for custom solutions and expert support.