Las herramientas de corte de carburo de tungsteno son conocidas por su dureza y larga vida útil. Sin embargo, tras un uso intensivo, incluso las mejores herramientas de carburo se desgastan o pierden filo. En lugar de desecharlas, muchas herramientas se pueden afilar y reacondicionar para recuperar su rendimiento de corte.

En esta guía, explicaremos en un inglés sencillo cómo afilar y reacondicionar herramientas de corte de carburo de tungsteno, paso a paso. También aprenderá a identificar cuándo es necesario afilar y a elegir el método y el equipo adecuados.

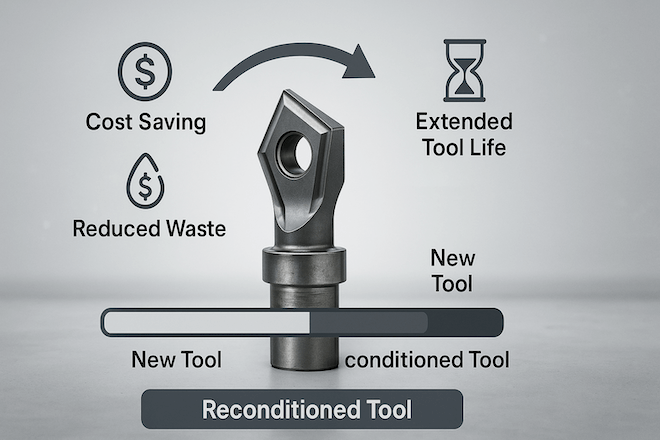

¿Por qué reacondicionar herramientas de carburo de tungsteno?

Las herramientas de carburo de tungsteno son más caras que las de acero convencionales. Por eso, afilarlas y reutilizarlas es una buena idea. El reacondicionamiento le ayuda a:

Ahorre dinero en reemplazos

Mantener la geometría y precisión de la herramienta

Reducir el tiempo de inactividad en la producción

Reducir los residuos y apoyar la sostenibilidad

Retop ofrece una gama completa de herramientas de corte de carburo con servicios de reafilado y reafilado. Puede explorar más aquí: Herramientas de corte de carburo de tungsteno.

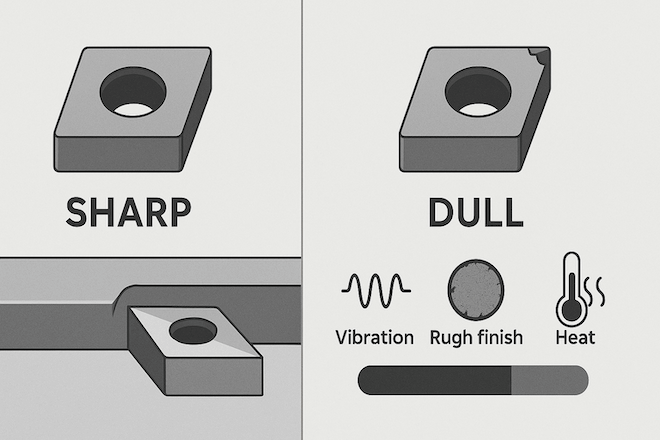

Señales comunes de que su herramienta de carburo necesita afilarse

¿No sabes cuándo reafilar? Presta atención a estas señales:

Filo de corte sin filo

Vibración o traqueteo durante el mecanizado

Mal acabado superficial en la pieza de trabajo

Mayor fuerza de corte o presión de la herramienta

Desgaste visible en los flancos o esquinas de la herramienta

El uso de una herramienta desafilada durante demasiado tiempo puede provocar sobrecalentamiento, rotura de la herramienta o defectos en las piezas.

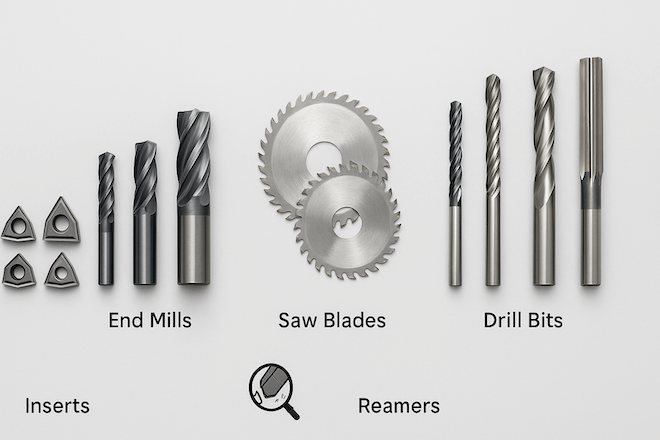

Tipos de herramientas de carburo de tungsteno que se pueden reacondicionar

Hay muchos tipos de herramientas de carburo que se pueden reacondicionar si no están demasiado astilladas:

Herramientas de carburo personalizadas

Explora nuestro catálogo completo aquí:

👉 Herramientas de corte de carburo personalizadas

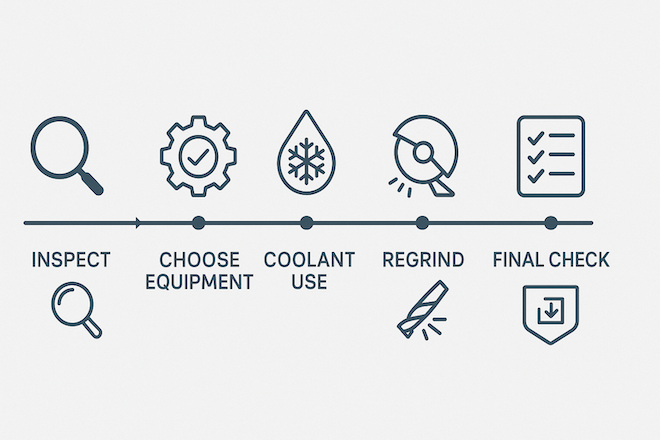

Paso a paso: Cómo afilar herramientas de corte de carburo de tungsteno

1. Inspeccione la herramienta cuidadosamente

Antes de afilar, inspeccione la herramienta bajo una luz brillante o con una lupa. Compruebe lo siguiente:

Marcas de desgaste

Grietas

Papas fritas

bordes rotos

Las herramientas muy dañadas pueden no merecer la pena afilarlas.

2. Elija el equipo de afilado adecuado

Para afilar carburo de tungsteno se requieren abrasivos de diamante o muelas de CBN. Las muelas de amolar convencionales no sirven.

Las máquinas y herramientas comunes incluyen:

Afiladora de herramientas CNC

Rectificadora de superficies de precisión

Afiladora universal de herramientas y cuchillas

Muelas de diamante (de resina o aglomerante vitrificado)

Para herramientas complejas o revestidas, se recomienda un servicio profesional.

3. Use refrigerante o lubricación

El rectificado genera calor, lo que puede dañar el carburo. Utilice siempre:

Refrigerante soluble en agua o

refrigerante a base de aceite

Esto ayuda a reducir las grietas térmicas y preserva la dureza de la herramienta.

4. Rectificar el filo

Respete la geometría original al reafilar. Las piezas clave para reafilar incluyen:

Ángulos de espacio libre primarios y secundarios

Ángulos de inclinación

Bordes de flauta (para taladros y fresas)

Radio de esquina o chaflán

Utilice ruedas de diamante de grano fino para obtener un borde suave y afilado.

5. Limpiar e inspeccionar nuevamente

Después del afilado:

Limpiar la herramienta

Compruebe si hay grietas en la superficie

Pruebe el rendimiento del corte si es posible

Si tiene un recubrimiento (como TiAlN o TiCN), es posible que deba volver a recubrir la herramienta después de afilarla.

Obtenga más información sobre los recubrimientos aquí:

👉 Guía de recubrimiento de carburo de tungsteno

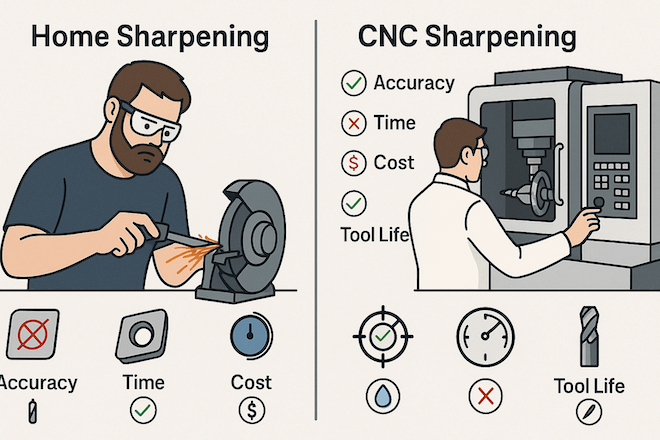

Afilado DIY vs. Afilado profesional: ¿cuál es mejor?

| Factor | Afilado DIY | Servicio profesional |

|---|---|---|

| Costo | Más bajo si hay pocas herramientas | Más rentable para lotes |

| Precisión | Depende de la habilidad y el equipo. | Alta precisión |

| Tiempo | Pérdida de tiempo | Entrega más rápida |

| Manejo de recubrimientos | No es posible hacerlo internamente | Puede quitar y volver a aplicar recubrimientos. |

| Vida útil de la herramienta | Puede acortarse con una técnica deficiente | Vida útil prolongada de la herramienta garantizada |

Consejo: Para herramientas de alta precisión como insertos de carburo y fresas de extremoEs más seguro utilizar un servicio de rectificado profesional como Retocar.

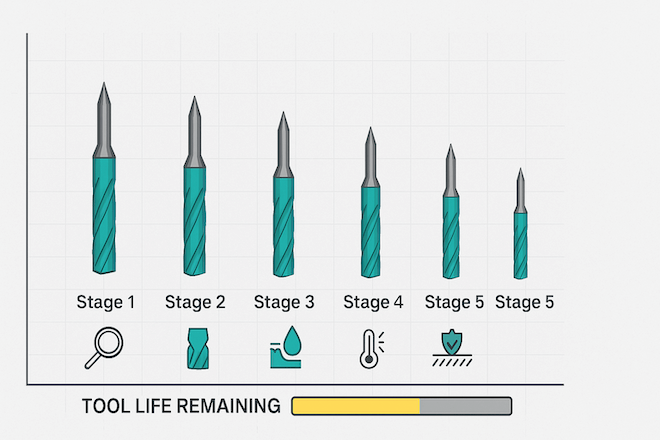

¿Cuántas veces se puede reafilar una herramienta de carburo?

Esto depende de:

Tipo de herramienta

Tamaño inicial

Solicitud

Calidad de reafilado

Normalmente, las herramientas de carburo se pueden afilar de 3 a 5 veces antes de necesitar un reemplazo completo.

Las herramientas de carburo personalizadas con filos más gruesos pueden permitir más reafilados. Consulte nuestra guía aquí:

👉 Por qué las herramientas de corte de carburo de tungsteno tienen una resistencia al desgaste superior

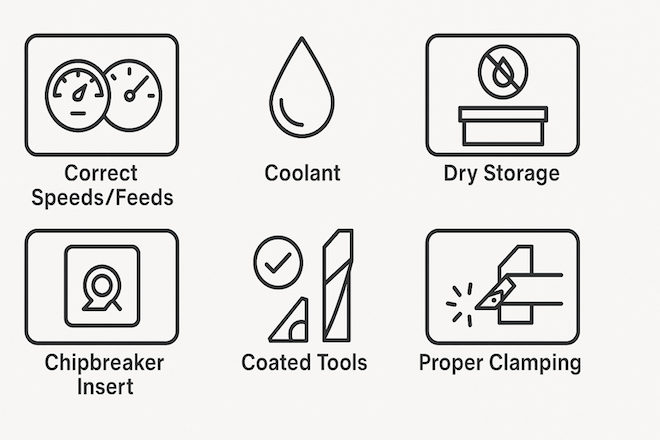

Cómo maximizar la vida útil de la herramienta entre afilados

Utilice estos consejos para prolongar la vida útil de la herramienta y retrasar el afilado:

Elige lo correcto grado de carburo para tu material

Utilice velocidades de corte y avances adecuados

Aplicar refrigerante durante el funcionamiento

Evite cargas de choque o cortes interrumpidos

Guarde las herramientas en cajas secas y acolchadas.

Utilice herramientas de carburo recubiertas para una mayor vida útil.

Más consejos aquí:

👉 Consejos de mantenimiento para prolongar la vida útil de sus herramientas de corte de carburo de tungsteno

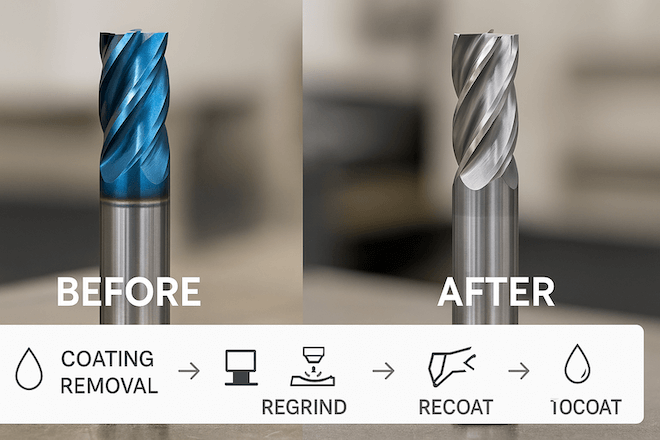

¿Es posible reafilar las herramientas recubiertas?

Sí, pero primero hay que retirar el recubrimiento. La mayoría de los recubrimientos se eliminan con:

Decapado químico

Grabado de plasma

Después de afilarla, la herramienta se puede recubrir nuevamente para una protección continua.

Servicios de reacondicionamiento confiables de Retop

En Retop, no solo suministramos herramientas de carburo de tungsteno de alto rendimiento, sino que también ofrecemos:

Inspección y evaluación de herramientas

Afilado y reafilado de precisión

Servicio de repintado de herramientas

Reparación o remodelación de herramientas personalizadas

Nuestro avanzado equipo de rectificado CNC y nuestro estricto control de calidad garantizan que sus herramientas reacondicionadas funcionen como nuevas.

Conclusión

Afilar y reacondicionar herramientas de carburo de tungsteno es una forma inteligente de prolongar su vida útil y ahorrar dinero. Con el equipo y la técnica adecuados, o eligiendo un proveedor de confianza como Retop, puede revitalizar sus herramientas desafiladas y mantener sus operaciones funcionando eficientemente.

Si no está seguro de cómo reafilar o necesita ayuda, contáctenos. Estamos aquí para ayudarle a mantener y optimizar sus herramientas de carburo.