Elegir lo correcto tungsten carbide bushing is not just about picking a size or part number.

It’s about making sure the bushing fits your equipment’s load, pressure, temperature, and medium — all while delivering maximum service life and minimal downtime.

Tungsten carbide bushings are used in pumps, compressors, turbines, and rotating equipment where mechanical stress and wear are constant challenges.

The wrong specification can lead to premature wear, shaft damage, or leakage — increasing maintenance costs and downtime.

This guide explains how to select and specify the correct tungsten carbide bushing for your system based on design, material grade, application, and operating environment.

Understand the Function of Tungsten Carbide Bushings

Before choosing a grade or geometry, it’s important to understand why tungsten carbide bushings are used.

They are designed to:

Support and align rotating shafts

Reduce friction between moving parts

Withstand high loads and pressures

Resist corrosion, wear, and deformation

Operate in fluids such as water, oil, gas, or chemicals

Because tungsten carbide combines ceramic hardness with metallic tenacidad, it offers much longer life compared to bronze or stainless steel.

Step 1: Define Operating Conditions

The first step in specifying a tungsten carbide bushing is to define the operating conditions. These parameters determine the grade, binder content, and surface finish.

| Parámetro | Typical Range / Value | Por qué es importante |

|---|---|---|

| Pressure | Up to 100 MPa | Determines required compressive strength |

| Temperatura | -200°C to +600°C | Affects binder selection and dimensional stability |

| Fluid Medium | Water, oil, gas, chemical, slurry | Controls corrosion and erosion requirements |

| Load Type | Radial or axial | Impacts geometry and wall thickness |

| Speed | Up to 30 m/s | Defines lubrication and heat dissipation needs |

The more accurately you define these parameters, the easier it becomes to choose the correct tungsten carbide grade and design.

Step 2: Choose the Correct Grade

Tungsten carbide bushings come in several grades, each designed for a specific combination of dureza, tenacidad, y Resistencia a la corrosión.

| Calificación | Tipo de carpeta | Dureza (HRA) | Best Suited For |

|---|---|---|---|

| YG6 | Cobalt | 91 | High wear, low shock applications (water pumps, dies) |

| YG8 | Cobalt | 89 | General-purpose industrial bushings |

| YG11 | Cobalt | 87 | Heavy-duty oil, gas, and drilling applications |

| YN6 | Nickel | 90 | Corrosive media — seawater, acids, or chemicals |

Cobalt-bonded grades (YG series): High strength, great for mechanical impact.

Nickel-bonded grades (YN series): Excellent corrosion resistance for chemical and marine systems.

Step 3: Determine Dimensional Requirements

Bushings must fit precisely into housings and onto shafts.

When specifying, confirm inner diameter (ID), outer diameter (OD), length, and tolerance level.

| Parámetro | Typical Range | Nivel de tolerancia |

|---|---|---|

| Inner Diameter (ID) | 10 mm – 300 mm | ±0,01 mm |

| Outer Diameter (OD) | 20 mm – 500 mm | ±0.02 mm |

| Longitud | 10 mm – 300 mm | ±0,05 mm |

For high-speed or precision applications, ground and lapped tolerances are essential to maintain alignment and reduce vibration.

Step 4: Consider the Working Medium

The fluid or gas that passes through your system has a big impact on bushing selection.

| Working Medium | Recommended Material | Notes |

|---|---|---|

| Clean Water | YG6 | Economical and high hardness |

| Seawater | YN6 | Nickel binder for corrosion resistance |

| Light Oil | YG8 | Balanced toughness and hardness |

| Chemical Fluids | YN9 | Chemical stability and low reactivity |

| Slurry | YG11 | High toughness for abrasive particles |

Step 5: Verify Surface Finish and Flatness

For seals or rotating bushings, surface finish is crucial. A polished finish (Ra ≤ 0.05 µm) minimizes friction and wear.

Some high-performance bushings also include micro-pockets or grooves to retain lubrication, improving service life in low-lubrication environments.

Step 6: Specify Tolerances and Mounting Method

Bushings can be mounted in different ways depending on operating temperature and pressure:

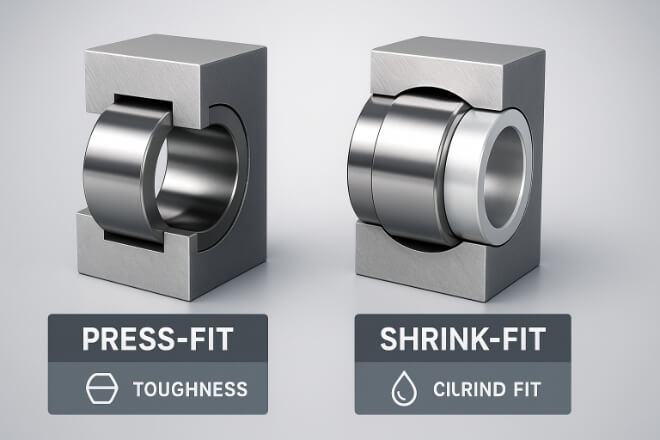

Press fit: Common for fixed sleeves.

Shrink fit: Ideal for thermal expansion control.

Adhesive bonding: For low-temperature or non-metallic housings.

Each mounting type may affect final tolerances, so these should be specified clearly on engineering drawings.

Step 7: Confirm Testing and Quality Standards

When ordering tungsten carbide bushings, always check the supplier’s testing certifications and manufacturing standards.

Las pruebas comunes incluyen:

Dureza (HRA or HV)

Surface finish (Ra measurement)

Tolerancia dimensional verification

Resistencia a la corrosión (acid or salt spray test)

These ensure consistent performance across all batches.

Conclusión

Specifying the right tungsten carbide bushing goes beyond material choice — it’s about understanding your system’s load, environment, and geometry.

A properly selected bushing offers:

Mayor vida útil

Less maintenance

Better energy efficiency

Lower lifecycle cost

By defining conditions, choosing the right grade, and confirming dimensions and surface finish.

You can make sure your tungsten carbide bushings perform reliably under any environment — from high-speed compressors to corrosive chemical pumps.

Si desea conocer más detalles sobre alguna empresa, no dude en contactarnos. Contáctanos.