Automation tools are at the heart of modern manufacturing, improving efficiency, precision, and consistency. The performance of these tools depends heavily on the quality and durability of the cutting components used.

Puntas de carburo de tungsteno are a popular choice for automation tools due to their exceptional dureza, resistencia al desgaste, and heat resistance.

In this blog, we will explore how tungsten carbide tips enhance the efficiency of automation tools, contributing to faster production times, reduced downtime, and lower operational costs.

Why Tungsten Carbide Tips Are Ideal for Automation Tools

Tungsten carbide tips are an ideal choice for automation tools because of their ability to maintain performance over time, even under challenging conditions.

Here are some of the key properties that make them well-suited for automation:

1). Dureza and Durability

Tungsten carbide is one of the hardest materials available, second only to diamond. This hardness allows carbide tips to maintain sharp cutting edges even during prolonged use.

As automation tools are often used in continuous production cycles, the durability of tungsten carbide ensures that the tools remain efficient and effective throughout their operational life.

In automation processes, cutting tools are subjected to wear and tear from constant contact with materials.

Tungsten carbide tips resist wear far better than many other materials, ensuring consistent cutting performance and reducing the frequency of tool replacements.

This extended tool life leads to fewer interruptions in the production process and reduces maintenance costs.

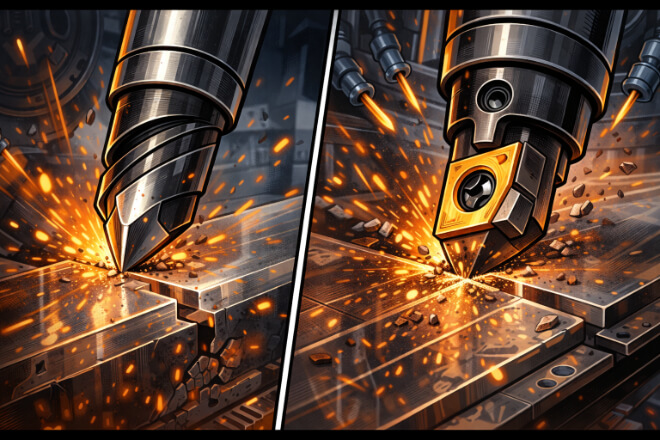

3). Heat Resistance

High-speed cutting operations generate significant heat, which can cause tools to lose hardness and performance.

Tungsten carbide tips are highly resistant to heat, ensuring that the tools maintain their cutting edge even in high-temperature environments.

This makes them ideal for high-speed automation processes where precision and tool integrity are critical.

Enhancing Precision and Consistency with Tungsten Carbide Tips

Precision and consistency are key factors in automation, especially when high-volume production and tight tolerances are required. Tungsten carbide tips help improve the accuracy and repeatability of automation tools.

1). Maintaining Sharp Edges for Precision

The hardness of tungsten carbide helps maintain sharp cutting edges for longer periods, ensuring that automation tools produce precise cuts and consistent results.

Sharp tools reduce the chances of error and provide smoother cuts, which is especially important in industries such as electronics and automotive manufacturing, where high precision is crucial.

2). Consistency in High-Volume Production

In automation, the ability to maintain consistent performance over long periods of operation is essential.

Tungsten carbide tips retain their cutting capabilities throughout extended runs, minimizing fluctuations in performance.

This consistency leads to higher-quality products and fewer defects, which is important for industries focused on mass production.

3). Reduced Tool Deflection

Tool deflection can lead to inaccuracies in the cutting process.

Tungsten carbide tips are more rigid and resistant to deflection than many other materials, ensuring that automation tools maintain stability during operations.

This rigidity ensures that parts are produced within the required specifications without deviations caused by tool flexing.

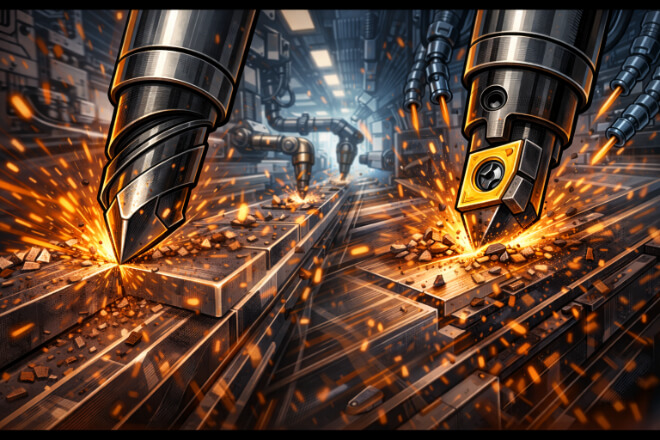

Increasing Cutting Speed and Productivity

Automation tools are designed to operate at high speeds to maximize productivity.

Tungsten carbide tips are well-suited for high-speed cutting due to their durability and ability to handle increased cutting forces without losing effectiveness.

1). High-Speed Cutting Capabilities

Tungsten carbide tips can withstand high cutting speeds without losing their hardness or sharpness.

This ability to perform at high speeds significantly improves the throughput of automation tools, enabling faster production times and increased efficiency.

2). Minimizing Downtime

Because tungsten carbide tips maintain their cutting ability over extended periods, they help reduce tool changeovers, which are often necessary with other materials.

This reduction in downtime contributes to a more efficient and continuous production process.

3). Faster Production Cycles

With the durability of tungsten carbide tips, automation tools can maintain high-speed operations for longer periods.

This leads to shorter production cycles and faster manufacturing times, which is essential in industries that need to meet high production targets.

Cost Efficiency with Tungsten Carbide Tips in Automation Tools

While tungsten carbide tips may have a higher upfront cost, their long-term benefits make them a cost-effective choice for automation tools.

1). Lower Maintenance and Replacement Costs

Tungsten carbide tips have a much longer lifespan than tools made from softer materials.

Their wear resistance and heat tolerance mean fewer tool replacements and reduced maintenance costs.

Over time, the initial investment in carbide tips pays off through extended tool life and lower operational costs.

2). Reduced Tool Failures

Tool failures in automation can lead to costly downtime and lost productivity.

Tungsten carbide tips are more resistant to breakage, chipping, and wear, reducing the risk of tool failure during operation.

This increased reliability ensures that production lines run smoothly and without interruption.

3). Higher ROI

The combination of durability, precision, and productivity increases the overall return on investment (ROI) for businesses using tungsten carbide tips in their automation tools.

The reduced need for tool replacements, less downtime, and improved productivity contribute to a higher ROI in the long run.

Applications of Tungsten Carbide Tips in Automation Tools

Tungsten carbide tips are used in various automation tools across multiple industries.

Their ability to perform under high-speed and high-precision conditions makes them essential in the following applications:

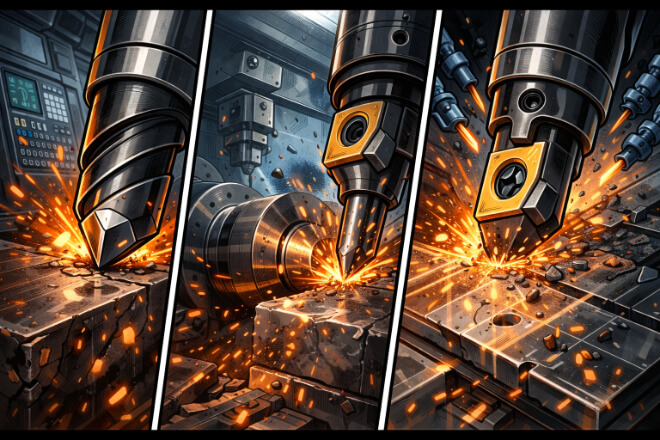

1). Robotics and CNC Machines

Tungsten carbide tips are widely used in robotics and CNC machinery for cutting, drilling, and shaping materials.

Their precision and durability make them ideal for producing complex components in industries like aeroespacial, automotor, and medical device manufacturing.

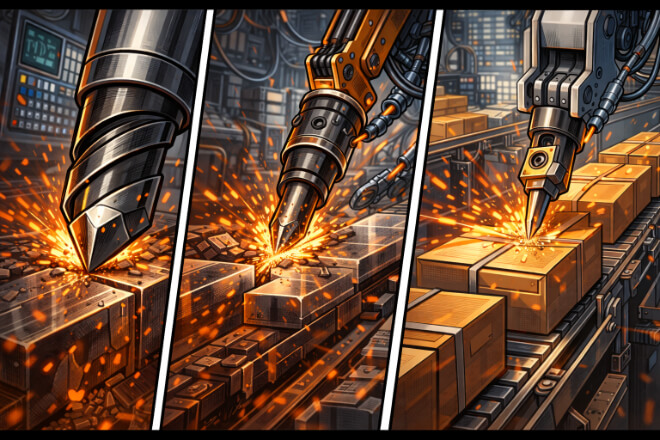

2). Assembly Line Automation

In assembly line automation, tungsten carbide tips are used for operations that require high precision and consistent performance.

From fastening and cutting to shaping and trimming, carbide tips ensure that every part is produced with the required quality and consistency.

3). Packaging and Food Processing

In packaging and food processing, automation tools with tungsten carbide tips are used for cutting, sealing, and packaging products at high speeds.

The wear resistance of carbide tips ensures that these tools remain efficient over time, even when handling tough materials.

Conclusión

Tungsten carbide tips significantly enhance the performance of automation tools, offering numerous benefits such as improved precision, increased cutting speeds, longer tool life, and reduced downtime.

These benefits lead to higher productivity, cost savings, and a better return on investment. Whether in CNC machinery, robotics, or assembly line operations, tungsten carbide tips are essential for businesses looking to optimize their manufacturing processes.

Investing in carbide tools ensures that automation systems perform at their best, contributing to more efficient, reliable, and cost-effective operations.

Si desea conocer más detalles sobre alguna empresa, no dude en contactarnos. Contáctanos.