En industrias como minería, manufacturing, and construction, drilling and cutting accuracy are essential for ensuring high-quality results and minimizing waste.

Puntas de carburo de tungsteno have become the go-to solution for achieving precise cuts and holes due to their exceptional dureza, durability, and resistance to wear.

This blog will explore how tungsten carbide tips improve drilling and cutting accuracy, and why they are a wise investment for businesses seeking consistent, high-performance results.

What Makes Tungsten Carbide Tips Ideal for Accurate Drilling and Cutting?

Tungsten carbide tips are widely used in various industries for drilling and cutting due to their unique properties that enhance both performance and accuracy.

These properties are key to achieving consistent and precise results.

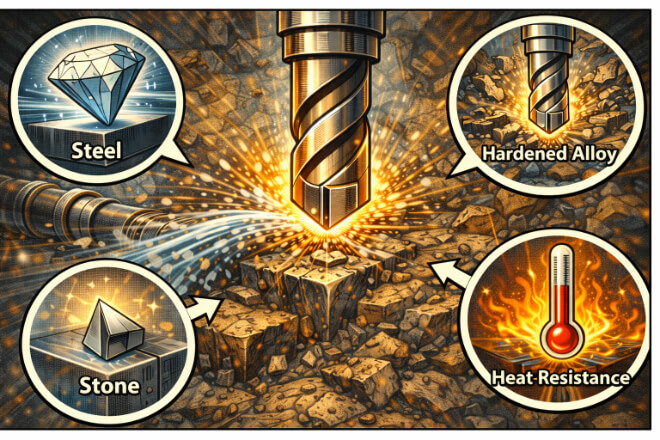

1). Dureza and Sharpness

Tungsten carbide is one of the hardest materials known, second only to diamond.

This hardness allows carbide tips to maintain sharp edges over extended periods, which is crucial for achieving precise cuts and holes.

Sharp tips reduce the chances of tool deflection or deviation during the drilling or cutting process, ensuring accuracy.

The wear resistance of tungsten carbide tips is exceptional. As tools come into contact with hard materials, wear can cause them to lose their sharpness, leading to less accurate cuts and increased production time.

Tungsten carbide tips resist wear, maintaining their cutting edges and ensuring consistent accuracy throughout their lifespan.

3). Heat Resistance

High temperatures can cause tool deformation and loss of cutting edge sharpness.

Tungsten carbide’s high thermal conductivity helps it maintain its hardness even under heat, which is especially important in high-speed drilling and cutting operations where heat generation is common.

These properties ensure that tungsten carbide tips remain reliable and accurate, even in challenging working environments.

How Tungsten Carbide Tips Improve Drilling Accuracy

In drilling applications, achieving accuracy is crucial to ensure the correct size and shape of holes.

Tungsten carbide tips contribute significantly to the precision of drilling operations, particularly in industries like oil and gas, construction, and automotive manufacturing.

1). Consistent Hole Sizes and Shapes

Tungsten carbide tips maintain their sharpness throughout the drilling process, ensuring that each hole is drilled to the exact specifications.

This consistency is essential for industries that require precise hole dimensions for parts assembly or structural integrity.

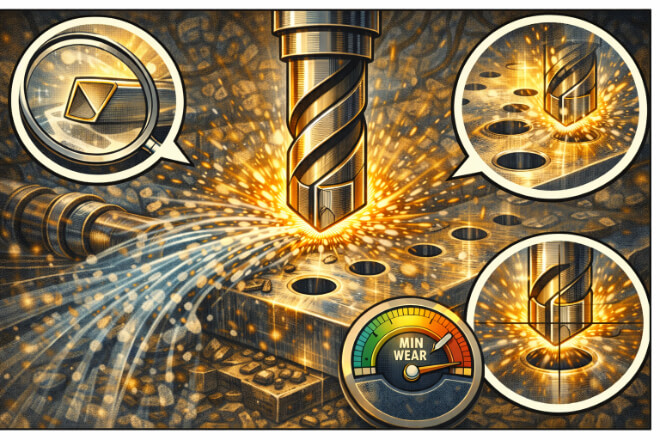

2). Reduced Tool Wear

As drilling progresses, tools tend to wear down, leading to a reduction in performance and accuracy.

Tungsten carbide tips resist wear, allowing them to maintain cutting precision and extend the tool’s service life.

This results in fewer tool changes, reducing downtime and improving overall productivity.

3). Minimized Tool Deflection

Tool deflection occurs when a tool bends under pressure, causing holes to be drilled off-center or at incorrect angles.

Tungsten carbide tips, due to their hardness and stiffness, are less likely to deflect during drilling, ensuring that holes are drilled exactly where they are needed.

How Tungsten Carbide Tips Improve Cutting Accuracy

Tungsten carbide tips are also widely used in cutting operations, providing enhanced accuracy in industries such as metalworking, woodworking, and plastics manufacturing.

1). Precise Edge Retention

Tungsten carbide tips maintain their sharpness and precision even after prolonged use, which is crucial for achieving accurate cuts in materials like steel, aluminum, and composites.

Consistent sharpness allows for smoother cuts and cleaner edges, which is particularly important for products requiring high-quality finishes.

2). Reduced Vibration and Chatter

Vibration and chatter during cutting can lead to inaccuracies, poor surface finishes, and tool wear.

Tungsten carbide tips, due to their stiffness and resistencia al desgaste, help reduce vibration, allowing for smoother cuts and more accurate results.

This stability ensures that the material is cut with minimal disruption, providing better precision.

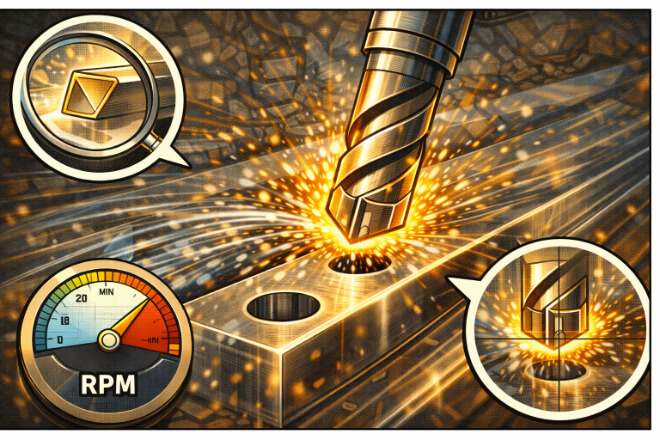

3). Increased Cutting Speeds

Tungsten carbide tips can operate at higher cutting speeds without sacrificing accuracy or tool life.

This capability allows manufacturers to increase throughput while maintaining the high precision needed for complex cuts.

Increased cutting speeds reduce machining time and costs while preserving accuracy.

Applications of Tungsten Carbide Tips in Precision Drilling and Cutting

Tungsten carbide tips are essential for precision drilling and cutting in various industries. Some of the most common applications include:

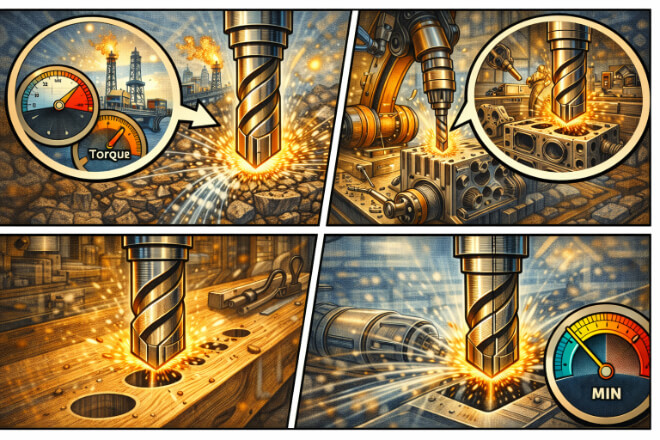

1). Petróleo y gas Industria

In oil and gas drilling, accuracy is crucial for reaching deep wells without damaging surrounding rock formations.

Tungsten carbide tips are used in drill bits to ensure precise drilling, even in tough conditions like hard rock and extreme depths.

2). Automotor Manufacturing

In automotive manufacturing, precise drilling and cutting are required for assembling high-precision components.

Tungsten carbide tips help ensure that holes are drilled accurately and cleanly, contributing to the overall quality and functionality of the parts.

3). Carpintería y Metalurgia

Tungsten carbide tips are widely used in woodworking and metalworking tools, such as saw blades and router bits.

Their precision ensures that materials are cut with smooth edges and minimal material loss.

4). Medical Device Manufacturing

In the medical industry, tungsten carbide tips are used to cut and drill materials like titanium and stainless steel.

Accuracy is critical to ensure that components fit perfectly and function as intended.

Maximizing Cutting Accuracy with Tungsten Carbide Tips

To ensure the best performance and accuracy, businesses should follow these best practices when using tungsten carbide tips:

1). Optimizing Cutting Parameters

Adjusting cutting speed, feed rate, and depth of cut can optimize the performance of tungsten carbide tips.

Ensuring that these parameters are set correctly helps achieve smoother cuts and extends the life of the tool.

2). Regular Tool Maintenance

Regular inspections and maintenance of carbide tips ensure that they maintain their sharpness and performance.

Resharpening or reconditioning tips when necessary can help prolong their lifespan and keep them performing at optimal levels.

3). Proper Storage and Handling

Tungsten carbide tips should be stored in a dry, clean environment to prevent corrosion or damage.

Proper handling is also essential to avoid chipping or breaking the tips, ensuring that they remain accurate and effective over time.

Conclusión

Tungsten carbide tips play a vital role in improving drilling and cutting accuracy, thanks to their hardness, wear resistance, and stability.

Whether in oil and gas drilling, automotive manufacturing, or medical device production, carbide tips ensure high-precision results that contribute to improved product quality and efficiency.

By understanding the properties of tungsten carbide and following best practices for their use, businesses can significantly enhance their drilling and cutting operations, saving time, reducing costs, and increasing overall productivity.

Si desea conocer más detalles sobre alguna empresa, no dude en contactarnos. Contáctanos.