Piezas de desgaste de carburo de tungsteno are some of the most trusted components in modern industry.

Known for their dureza, resistencia al desgaste, and long life, they are essential wherever equipment faces friction, heavy loads, or abrasive environments.

From drilling oil wells to stamping automotive parts, tungsten carbide helps businesses run more efficiently and reduce downtime.

This article explores the key industries that rely on tungsten carbide wear parts, why they are used, and what decision-makers should know to get the most value from them.

Minería y construcción

Minería is one of the toughest environments for machinery. Tools like drill bits, crushers, and Herramientas de corte face constant abrasion from rock and ore. Tungsten carbide is used in:

Drill bits for hard rock mining.

Wear plates in crushers.

Tunnel boring machine cutters.

In construction, carbide wear parts are used in road milling, trenching, and excavation equipment.

The ability of carbide to resist wear and impact saves companies money by reducing replacement frequency.

Industria del petróleo y el gas

El petróleo y gas sector depends heavily on tungsten carbide wear parts to deal with extreme pressure and corrosion. Key applications include:

Valve seats and seals.

Drill bit inserts for downhole tools.

Pump plungers and sleeves.

Carbide’s resistance to high temperature, pressure, and corrosive fluids makes it the preferred choice for oilfield operations, where downtime is extremely costly.

Metalworking and Machining

Tungsten carbide cutting tools dominate the machining industry. Whether in automotor, aeroespacial, or general manufacturing, carbide parts are found in:

Turning inserts.

End mills and drills.

Carbide tools enable high-speed machining, tighter tolerances, and longer tool life compared to steel.

This helps manufacturers increase productivity while lowering overall tooling costs.

Industria automotriz

Automotor production requires precision and durability. Piezas de desgaste de carburo se utilizan en:

Stamping dies for body panels.

Punches and forming tools.

Machining inserts for engine components.

The automotive industry values carbide for its ability to deliver consistency at scale, ensuring high-quality parts with reduced rework.

Aerospace and Defense

En aeroespacial, safety and performance are critical. Tungsten carbide is used in:

Cutting tools for titanium and superalloys.

Wear-resistant components in jet engines.

Specialized tooling for composite materials.

Defense applications also include armor-piercing components and heavy-duty wear parts for military equipment.

Carbide ensures performance in high-stress environments where failure is not an option.

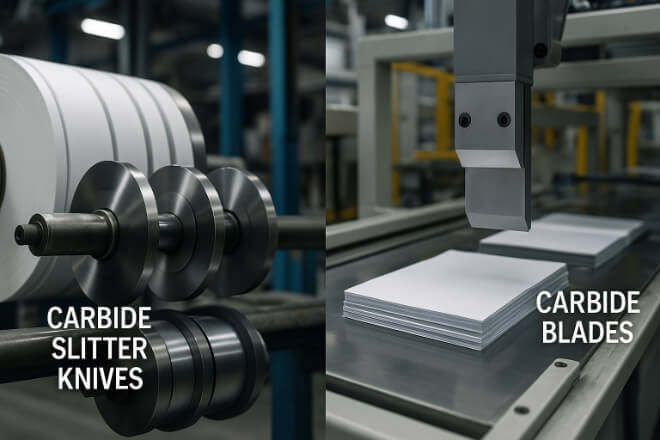

Paper, Textile, and Packaging

Industries that process softer but abrasive materials also depend on carbide. Examples include:

Cuchillas cortadoras en fábricas de papel.

Cuchillas en máquinas de corte textil.

Packaging machinery rollers and knives.

Carbide’s sharp edges and resistance to dulling ensure efficiency and reduce downtime in continuous production lines.

Woodworking and Furniture

Carbide-tipped tools dominate carpintería because of their ability to cut hardwoods, composites, and laminates without rapid dulling. Common applications include:

Router bits.

Planer knives.

Furniture makers and construction companies prefer carbide tools because they deliver cleaner cuts and longer tool life than steel alternatives.

Agriculture and Food Processing

Even agriculture benefits from carbide wear parts. Farmers and processors use carbide in:

Plowshares and tillage tools.

Feed mixers.

Food cutting and grinding equipment.

Carbide extends the life of parts exposed to soil abrasion and food-processing wear, lowering maintenance costs in high-use operations.

Conclusión

From heavy industries like mining and oil & gas to precision-driven sectors like aerospace and automotive, tungsten carbide wear parts are essential for modern production.

Their unique balance of hardness, toughness, and durability makes them the smart choice for reducing downtime and operational costs.

For decision-makers, investing in carbide wear parts is about more than durability—it’s about improving efficiency, saving money, and staying competitive in demanding markets.

Si desea conocer más detalles sobre alguna empresa, no dude en contactarnos. Contáctanos.