In pumps, compressors, turbines, and mixers, the seal system plays a critical role. A poor seal can lead to leaks, downtime, or even accidents.

For industries that deal with high pressure, speed, or aggressive fluids, choosing the right seal material is vital.

One of the most trusted solutions is the tungsten carbide seal ring. Known for its dureza and durability, this component offers properties that outperform many other sealing materials.

For decision-makers, knowing the key performance properties of tungsten carbide seal rings helps ensure reliable operation and cost savings.

¿Qué son los anillos de sello de carburo de tungsteno?

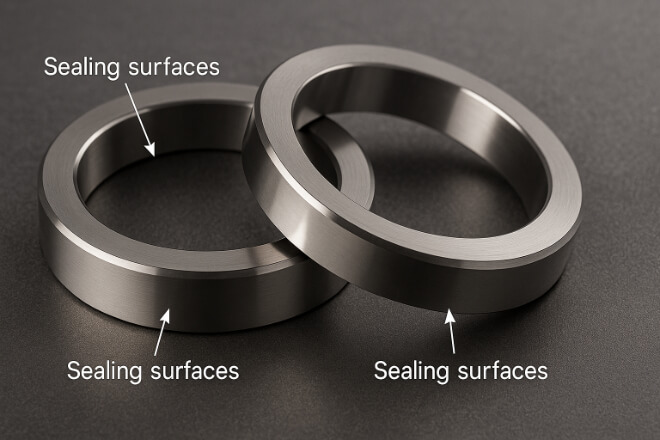

Tungsten carbide seal rings are mechanical sealing parts made by combining tungsten and carbon, usually with cobalt or nickel as a binder.

They are used in rotating machines to prevent leakage of fluids or gases.

Unlike rubber or standard steel rings, they are built to survive extreme wear, heat, and chemical exposure.

Typical industries include:

Petróleo y gas bombas y compresores

Chemical processing plants

Marine and offshore systems

Power generation turbines

Food and pharmaceutical mixers

Property 1: Exceptional Hardness

Tungsten carbide is almost as hard as diamond. This property gives seal rings the strength to resist scratches, erosion, and deformation.

Por qué es importante:

Withstands abrasive fluids like slurry or drilling mud

Keeps sealing surface smooth for longer

Reduces sudden breakdowns in heavy machinery

Hardness makes tungsten carbide a top choice for industries with abrasive liquids or solid particles in the flow.

Property 2: High Wear Resistance

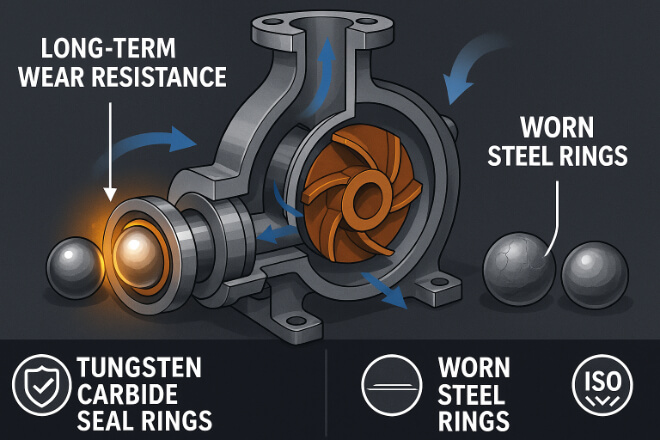

Every seal ring faces friction as two surfaces slide against each other. Tungsten carbide has excellent wear resistance, which means less material loss over time.

Beneficios de resistencia al desgaste:

Mayor vida útil

Costos de mantenimiento más bajos

Consistent sealing performance under long operation hours

This property is especially important for pumps in oil refineries, paper mills, and chemical plants, where machines run continuously.

Property 3: Corrosion Resistance

Different industries deal with different fluids. Some are neutral, while others are highly corrosive.

Tungsten carbide seal rings—especially those with nickel binder—perform well even in contact with acids, seawater, and other aggressive chemicals.

Por qué Resistencia a la corrosión matters:

Protects seals in chemical processing

Extends lifespan in marine environments

Reduces risk of leaks in sensitive applications

By resisting corrosion, tungsten carbide provides both safety and cost savings.

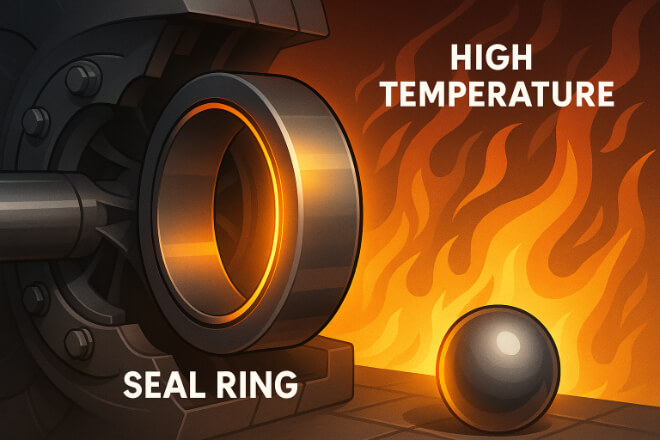

Property 4: Thermal Stability

Machines in power plants, turbines, and drilling rigs operate at high temperatures.

Tungsten carbide seal rings keep their strength even in these extreme conditions.

Beneficios clave:

Stable sealing at high heat

No loss of hardness during long operation

Reliable in both hot and cold environments

This property makes them ideal for energy, aeroespacial, and industrial pumps.

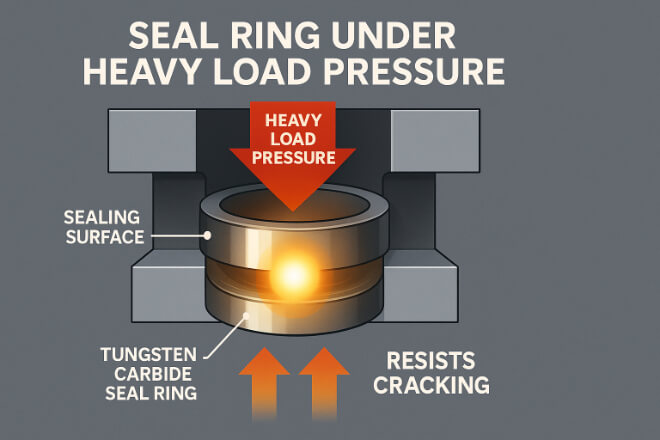

Property 5: High Strength and Toughness

While dureza protects against wear, strength and tenacidad prevent cracking or breaking under pressure.

Tungsten carbide’s densidad allows it to absorb high loads without failure.

Why it’s important:

Handles sudden pressure changes in pumps

Reduces the chance of catastrophic seal failure

Increases machine safety and reliability

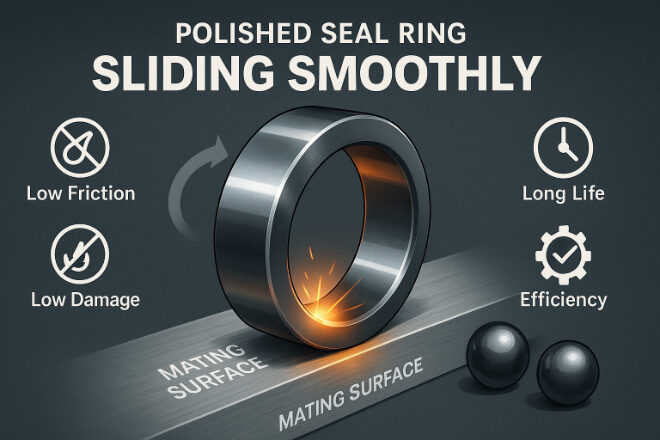

Property 6: Low Friction Surface

Seal rings must slide smoothly against mating surfaces. Tungsten carbide can be polished to a very low friction finish, reducing heat generation and energy loss.

Advantages of low friction:

Less energy consumption

Cooler operation of machinery

Less stress on other seal components

Property 7: Versatility Across Industries

La combinación de dureza, resistencia al desgaste, Resistencia a la corrosión, and toughness makes tungsten carbide seal rings suitable for many different sectors.

Ejemplos:

Petróleo y gas: Withstands abrasive drilling fluids

Chemical Plants: Handles corrosive acids and solvents

Marine Pumps: Resists seawater corrosion

Power Plants: Operates in hot turbines

Pharmaceutical: Provides clean and reliable sealing

Comparación con otros materiales

| Material | Key Characteristics |

|---|---|

| Stainless Steel | Cheaper but wears faster |

| Silicon Carbide | Good corrosion resistance but more brittle |

| Cerámica | High hardness but prone to cracking |

| Carburo de tungsteno | Best balance of hardness, toughness, and versatility |

Seal rings can be made from stainless steel, silicon carbide, or ceramics. Compared with these:

Steel: Cheaper but wears faster

Silicon Carbide: Good Resistencia a la corrosión but more brittle

Ceramics: High dureza but prone to cracking

Tungsten carbide offers the best balance of hardness, tenacidad, and versatility.

How to Select the Right Tungsten Carbide Seal Ring

Decision-makers should consider:

Binder Type – Cobalt for toughness, nickel for corrosion resistance

Application Conditions – Temperature, pressure, and fluid type

Surface Finish – Polished for low friction, coated for special needs

Supplier Quality – ISO certifications and proven industry experience

Best Practices for Use

To maximize performance:

Ensure correct installation and alignment

Use proper lubrication when required

Keep sealing environment free of dust and particles

Inspect regularly for cracks or uneven wear

Replace before total failure occurs

Mantenimiento y reemplazo

Even though tungsten carbide seal rings last long, they are not indestructible.

Maintenance tips:

Inspect every few weeks in critical systems

Look for leaks, noise, or vibration as warning signs

Replace with the same grade and size to ensure fit

Recycle old rings to save cost and support sustainability

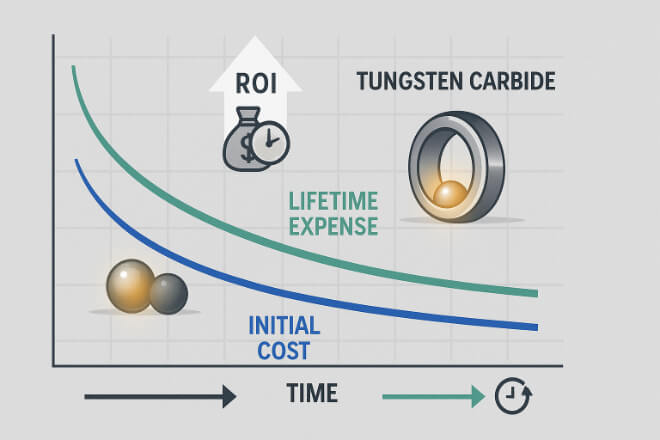

Cost and Business Value

Tungsten carbide seal rings are more expensive than standard steel rings, but the long-term value is clear:

5–10x longer lifespan

Lower replacement and labor costs

Reduced machine downtime

Safer and more reliable operations

For decision-makers, this means stronger ROI and improved productivity.

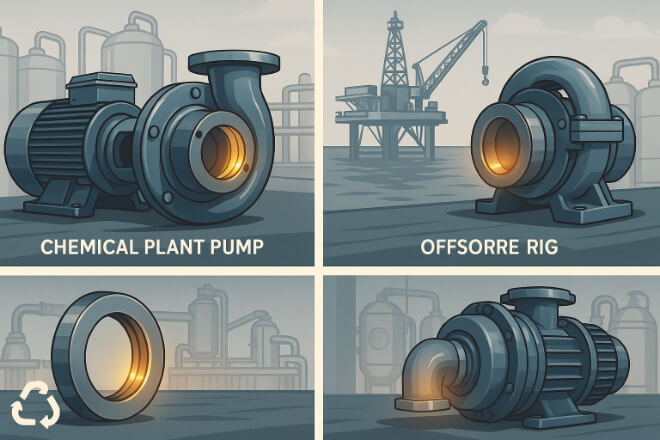

Ejemplos de casos

Chemical Plant

Nickel-bonded tungsten carbide rings resisted acid corrosion, extending service life from 3 months to 1 year.

Offshore Pumps

Seal rings lasted longer in seawater, reducing maintenance trips and cutting costs.

Oilfield Compressors

Cobalt-bonded rings survived high-pressure cycles, avoiding sudden failures.

Cómo conseguir anillos de sellado de carburo de tungsteno

When buying:

Choose experienced suppliers with global references

Check for ISO certification

Ask about binder types and customization

Confirm after-sales support and local inventory

Conclusión

Tungsten carbide seal rings are trusted worldwide because of their key performance properties: hardness, wear resistance, corrosion protection, thermal stability, and toughness.

For industries where reliability is critical, they deliver not just technical strength but also long-term business value.

Decision-makers who choose tungsten carbide seal rings invest in safety, efficiency, and cost savings.

Si desea conocer más detalles sobre alguna empresa, no dude en contactarnos. Contáctanos.