Las herramientas de corte de carburo de tungsteno son conocidas por su dureza, resistencia y resistencia al desgaste. Pero incluso las herramientas más resistentes requieren un cuidado adecuado para una mayor duración y un mejor rendimiento. Con un buen mantenimiento, puede reducir el tiempo de inactividad, ahorrar dinero y mejorar la calidad de su producción.

En este artículo, compartiremos consejos de mantenimiento sencillos y efectivos para prolongar la vida útil de sus herramientas de corte de carburo de tungsteno. Ya sea que las use para cortar metal, trabajar la madera o taladrar, estos consejos le ayudarán a aprovechar al máximo su inversión.

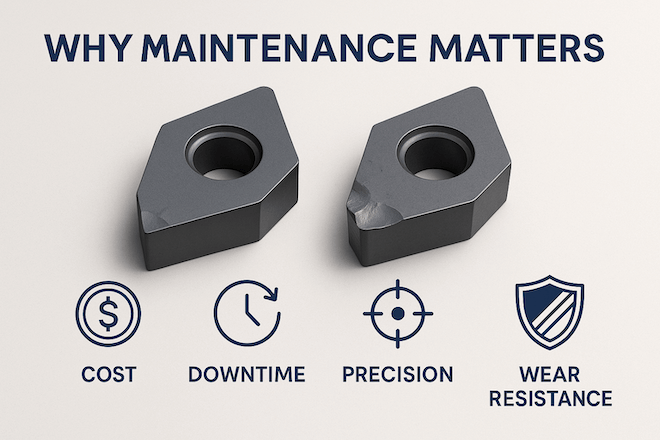

Por qué es importante el mantenimiento

Las herramientas de carburo de tungsteno se utilizan a menudo en entornos de alta velocidad, alta temperatura y alta presión. Con el tiempo, pueden desgastarse, astillarse o romperse si no se cuidan adecuadamente. El mantenimiento regular ayuda a:

Prevenir fallos de la herramienta

Mejorar la precisión del corte

Prolongar la vida útil de la herramienta

Reducir los costos de reemplazo

Mantener la calidad del producto

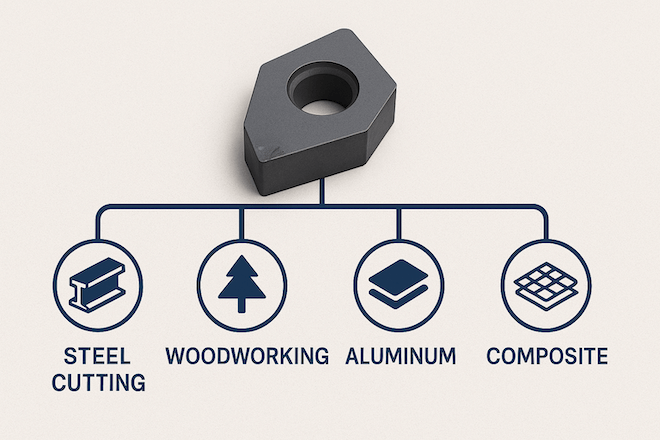

1. Elija la herramienta adecuada para el trabajo

El primer paso para el mantenimiento de su herramienta es seleccionar la correcta. Usar una herramienta incorrecta puede causar un desgaste o daños más rápidos. Elija siempre la herramienta correcta. grado de carburo, geometría y recubrimiento en función del material y las condiciones de corte.

Puede explorar más sobre la selección del grado de carburo en nuestra guía: Comprensión de los grados de carburo de tungsteno para aplicaciones de herramientas de corte.

2. Mantenga las herramientas limpias y secas

Después de cada uso, limpie las herramientas de corte para eliminar virutas, suciedad, aceite o refrigerante. Dejar residuos en la herramienta puede causar oxidación en el vástago o afectar el equilibrio de la herramienta.

Utilice un cepillo suave o un paño para limpiar la herramienta.

Evite utilizar agua; en su lugar, utilice alcohol o un disolvente suave.

Guarde las herramientas en un recipiente seco y sin polvo con el acolchado adecuado.

Esto es especialmente importante para herramientas de carburo de precisión como insertos de carburo, fresas de extremo, y anillos de sellado que son sensibles a la corrosión.

3. Controle periódicamente el desgaste de las herramientas

El desgaste del filo de la herramienta es normal, pero debe controlarse antes de que se agrave. Los signos comunes de desgaste incluyen:

Bordes opacos o astillados

Calor excesivo durante el corte

Mal acabado superficial

Aumento de la fuerza de corte o vibración

Al revisar sus herramientas periódicamente, podrá reemplazarlas o afilarlas a tiempo y evitar dañar la pieza de trabajo o la máquina.

Considere invertir en herramientas de carburo con recubrimientos como TiAlN o TiCN, que ofrecen mayor resistencia al desgaste. Obtenga más información en nuestro artículo: Guía de recubrimiento de carburo de tungsteno.

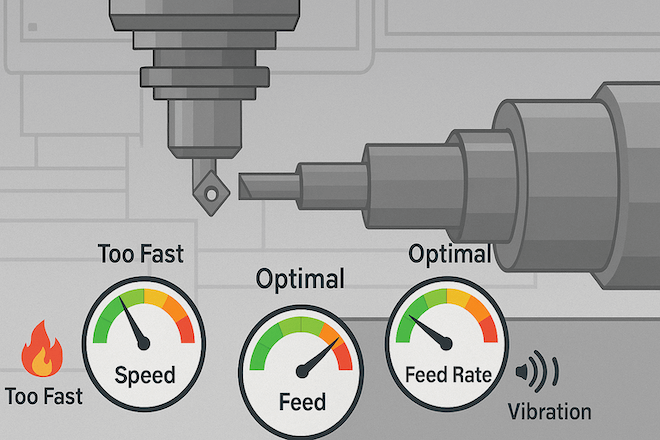

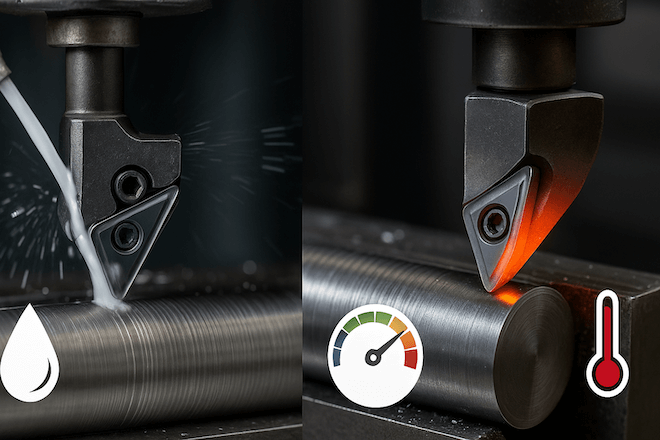

4. Utilice velocidades de corte y avances adecuados

Una de las principales causas de fallo de la herramienta es una velocidad de corte o avance incorrecta. Cada herramienta de corte de carburo tiene un rango ideal dependiendo del material.

Demasiado rápido = calor y daños en los bordes

Demasiado lento = frotamiento y mal acabado

Para evitar el desgaste prematuro:

Siga los parámetros de corte recomendados

Ajustar velocidades y avances para materiales duros

Utilice refrigerante o neblina de aire para reducir el calor.

Consulte las especificaciones de su herramienta o hable con su proveedor para obtener la mejor configuración.

5. Vuelva a afilar antes de que sea demasiado tarde

No espere a que su herramienta de carburo se desgaste por completo. Afilar las herramientas con anticipación puede:

Ahorre dinero en comparación con comprar unos nuevos

Mantener la geometría original de la herramienta

Mejorar la calidad del corte

Asegúrese de que el afilado lo realice un profesional con el equipo adecuado. En Retop, ofrecemos asistencia para reafilar herramientas de carburo de tungsteno y prolongar su vida útil.

6. Almacene las herramientas adecuadamente

Un almacenamiento inadecuado puede causar daños incluso cuando la herramienta no esté en uso. Siga estos consejos:

Utilice cajas o bandejas etiquetadas para diferentes herramientas

Mantenga los bordes afilados lejos de las superficies duras.

Evite ambientes húmedos o extremos.

Separe las herramientas recubiertas de las no recubiertas

Recomendamos almacenar las herramientas de carburo en embalajes antioxidantes o en cajas revestidas de espuma.

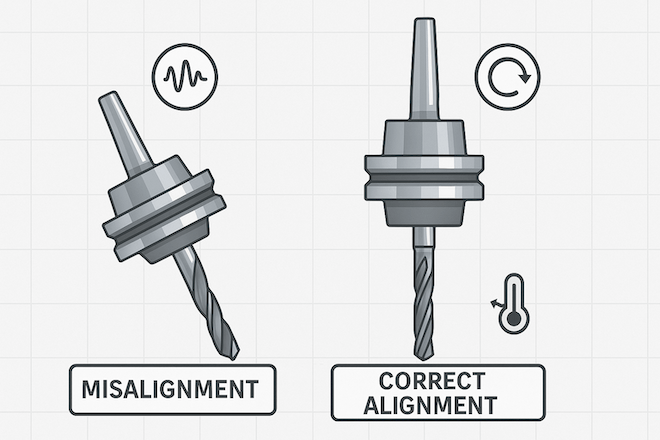

7. Utilice el soporte adecuado y la configuración de la máquina

Una buena herramienta puede funcionar mal si el portaherramientas o la máquina no están alineados. La desalineación provoca descentramiento, rotura o desgaste desigual de la herramienta.

Para evitar esto:

Utilice portaherramientas de precisión y verifique el descentramiento

Mantenga las máquinas calibradas

Evite la vibración excesiva

Apriete las herramientas firmemente pero evite aplicar un torque excesivo

Esto es especialmente importante para herramientas como brocas de carburo, barras de mandrinar y escariadores de carburo que dependen de una rotación precisa.

8. No ignore el refrigerante ni la lubricación

El calor es el enemigo del carburo de tungsteno. Una lubricación adecuada puede prolongar considerablemente la vida útil de la herramienta.

Utilice el refrigerante adecuado para su operación

Mantenga el refrigerante limpio y filtrado

Aplicar refrigerante directamente en la zona de corte

Evite el choque del refrigerante (enfriamiento repentino en una herramienta caliente)

Para el corte en seco, asegúrese de que la herramienta y la máquina estén diseñadas para esa condición. Algunas herramientas de carburo recubierto están diseñadas para el mecanizado en seco a alta velocidad.

9. Evite cortar superficies interrumpidas siempre que sea posible

El corte interrumpido, como al mecanizar piezas fundidas o bordes rugosos, somete la herramienta a un impacto adicional. Esto puede causar astillado o fractura en materiales de carburo frágiles.

Si es posible:

Utilice una sujeción estable para minimizar la vibración

Aplicar métodos de entrada en rampa o helicoidal

Utilice calidades de carburo más tenaces o insertos de carburo con diseños rompevirutas

10. Trabaje con un proveedor de confianza

Un buen proveedor puede ayudarle a elegir las herramientas adecuadas y ofrecerle soporte técnico. En RetocarOfrecemos una gama completa de herramientas de corte de carburo de tungsteno para diferentes industrias, que incluyen:

También ofrecemos asistencia técnica, diseño de herramientas y servicios OEM. Visite nuestras páginas de productos para obtener más información:

👉 Página de productos de herramientas de corte de carburo

Conclusión

Cuidar sus herramientas de corte de carburo de tungsteno no tiene por qué ser complicado. Siguiendo estos sencillos consejos de mantenimiento (limpieza, supervisión, uso de las velocidades correctas y almacenamiento adecuado), puede prolongar su vida útil y mejorar sus resultados.

Empieza poco a poco. Unos buenos hábitos pueden ser muy útiles para ahorrar costes y mantener la eficiencia de tu producción.