Handling corrosive liquids or gases is one of the toughest jobs for pumps, compressors, and válvulas.

El anillos de sellado inside this equipment face chemical attack, pressure changes, and constant friction. Two popular choices—nickel-binder carbide rings and cobalt-binder carbide rings—look similar but behave differently under stress.

This decision guide compares the two binder types, explaining their unique properties, best use cases, and tips for choosing the right one for corrosive environments.

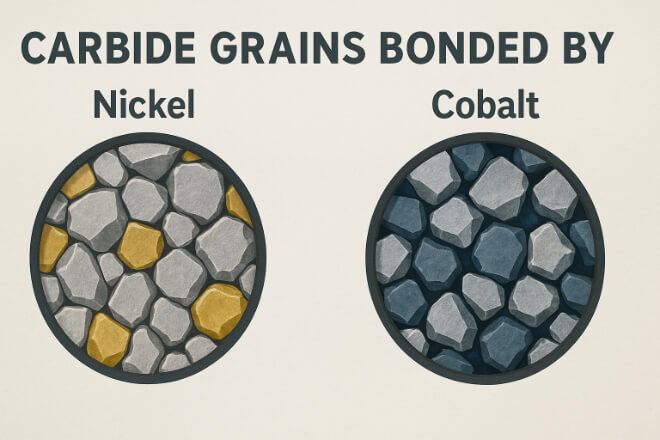

Understanding Binder Materials

Tungsten carbide on its own is extremely hard but brittle. A binder metal (nickel or cobalt) is added to improve tenacidad and bonding between carbide grains.

The binder changes how the seal ring reacts to chemicals, temperature shifts, and mechanical loads.

Nickel-Binder Carbide Rings

Nickel-binder grades are engineered for chemical stability.

1). Key Strengths

Superior Resistencia a la corrosión to acids, alkalis, and seawater.

Non-magnetic, useful for equipment with sensors or magnetic drives.

Reliable performance in marine and chemical processing

entornos.

2). Drawbacks

Less impact resistance in high-shock systems.

Higher purchase price than many cobalt-binder options.

3). Common Uses

Pumps transferring brine or aggressive chemicals.

LNG and cryogenic equipment exposed to condensation and salt.

Food-grade or pharmaceutical systems where corrosion is unacceptable.

Cobalt-Binder Carbide Rings

Cobalt-binder grades focus on mechanical toughness.

1). Key Strengths

Excellent shock and vibration resistance in pumps and mixers.

Handles sudden pressure spikes or shaft movement without cracking.

Typically more affordable and widely available.

2). Drawbacks

Less corrosion resistance in acidic or salty conditions.

Magnetic properties may interfere with sensitive instruments.

3). Common Uses

Mining slurry pumps and paper mill refiners.

Boiler feed pumps or compressors with stable fluids.

High-vibration industrial agitators or mixers.

Direct Comparison

| Aspect | Nickel-Binder | Cobalt-Binder |

|---|---|---|

| Resistencia química | Excellent for corrosive fluids | Moderate in corrosive environments |

| Resistencia a los golpes | Moderado | High toughness for vibration |

| Magnetic Properties | Non-magnetic | Magnetic—may affect sensors |

| Mejores aplicaciones | Seawater, acids, caustics | Mining slurry, boiler feed pumps |

| Relative Cost | Más alto | Más bajo |

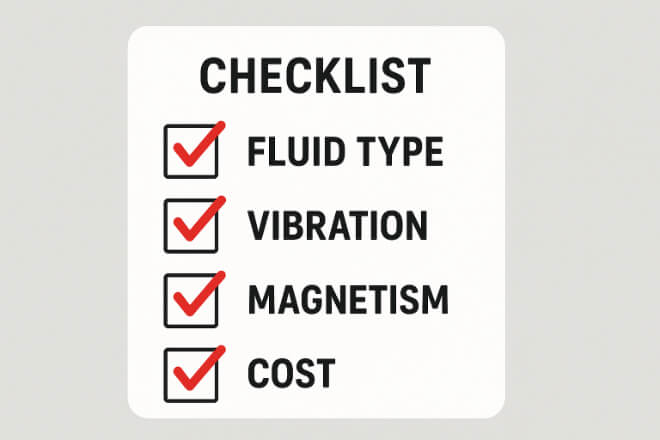

Decision Framework for Choosing a Binder

1). Identify Fluid Chemistry

Strong acids or seawater → Nickel-binder.

Clean water or non-corrosive fluids → Cobalt-binder.

2). Assess Mechanical Loads

High vibration or shaft deflection → Cobalt-binder.

Stable, low-vibration systems → Nickel-binder for Resistencia a la corrosión.

3). Consider Equipment Sensitivity

Magnetic interference risk → Choose nickel-binder.

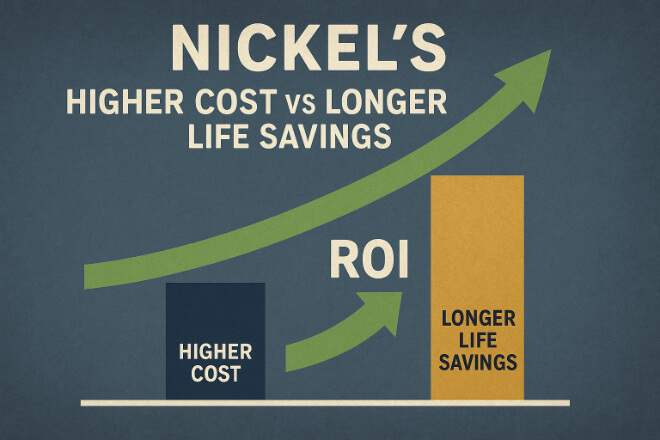

4). Review Budget and ROI

Nickel’s higher price may pay off if corrosion failures are expensive.

Ejemplos de la industria

Maintenance Tips

Inspect during planned outages for pitting or cracking.

Replace as pairs to maintain sealing balance.

Use proper flushing systems to remove particles.

Store spares in clean, dry conditions to prevent contamination.

Información sobre costos y retorno de la inversión

Nickel-binder’s cost is higher but prevents expensive corrosion failures.

Cobalt-binder reduces upfront costs for less aggressive fluids.

Correct choice extends service life by 30–50%, improving uptime.

Consideraciones ambientales y de seguridad

Proper binder choice prevents leaks of hazardous fluids into the environment and reduces workplace risks. Reliable sealing also supports compliance with chemical handling regulations.

Conclusión

Nickel-binder carbide rings excel in corrosive and marine environments, while cobalt-binder carbide rings shine in vibration-heavy or high-shock systems.

Decision-makers should match binder type to fluid chemistry, vibration levels, and equipment sensitivity to achieve maximum reliability, safety, and cost efficiency.

Si desea conocer más detalles sobre alguna empresa, no dude en contactarnos. Contáctanos.

Un comentario

It is very useful to me it given knowledge to me

Thank you very much