Tungsten carbide is renowned for its exceptional dureza, resistencia al desgaste, and durability, making it a popular choice for industrial applications such as bushings, bearings, and seals.

However, even tungsten carbide can face issues like friction and galling when paired improperly with other materials. These issues can result in excessive wear, damage, and ultimately failure of machinery components.

In this article, we’ll explore how proper pairing of tungsten carbide with compatible materials can reduce friction and galling, improve the performance of your machinery, and increase the longevity of your components.

What is Galling and How Does It Affect Tungsten Carbide?

1). Understanding Galling

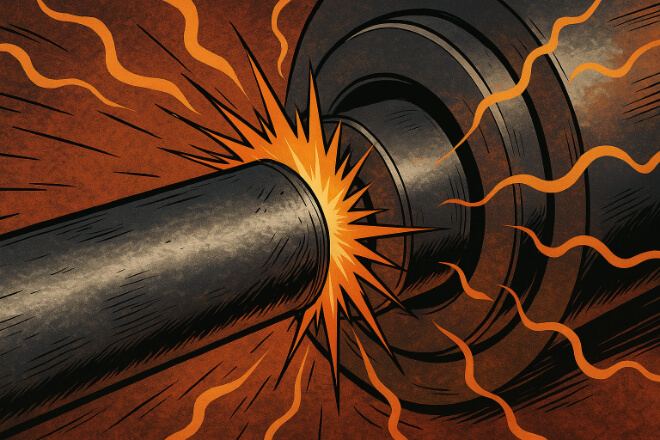

Galling is a form of adhesive wear that occurs when two materials slide over each other, causing friction that leads to the transfer of material from one surface to another.

This process results in rough surfaces, scoring, and eventually damage. Galling is particularly problematic in high-pressure, high-load applications, where high friction can accelerate wear.

How It Affects Tungsten Carbide:

When tungsten carbide is paired with an incompatible material, galling can quickly occur, leading to significant damage.

This is because tungsten carbide, while hard, is also brittle and can fracture when exposed to high shear forces.

Example: A tungsten carbide bushing paired with a steel shaft under high pressure may experience galling due to the mismatch in material dureza and lubricating properties.

2). Consequences of Galling on Equipment

Increased Wear: Galling increases friction between moving parts, which accelerates wear and reduces the lifespan of both components.

Surface Damage: Galling creates scratches and pits on the surface of both materials, leading to loss of material and reduced functionality.

Operational Failures: As galling worsens, it can result in seizing, failure of machinery, and costly downtime.

The Role of Friction in Tungsten Carbide Pairing

1). Understanding Friction and Its Impact

Friction is the resistance to motion that occurs when two surfaces slide over one another.

In industrial machinery, friction is an inevitable part of operation, but excessive friction can lead to increased wear, overheating, and ultimately damage to the components.

Tungsten Carbide and Friction:

Tungsten carbide has an extremely high coefficient of friction when paired with softer materials.

However, its dureza means it can also be prone to abrasive wear if not properly paired with materials that are more compatible in terms of frictional characteristics.

2). The Impact of High Friction on Machinery

Excessive friction between tungsten carbide and other materials can lead to:

Increased Heat Generation: High friction generates heat, which can cause thermal expansion, deformation, and potential failure of the material.

Damage to Components: Prolonged friction causes surface degradation, loss of material, and the development of cracks or galling.

Example: In high-speed rotating machinery, such as pumps or compressors, high friction can accelerate wear on tungsten carbide seals and bushings, reducing their effectiveness.

Proper Pairing of Tungsten Carbide for Reduced Friction and Galling

1). Selecting the Right Materials for Pairing

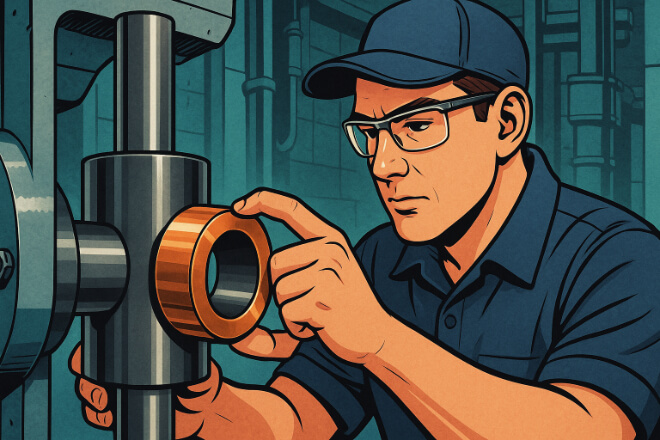

Proper material pairing is essential for minimizing friction and preventing galling in tungsten carbide components.

When selecting materials for pairing with tungsten carbide, it’s crucial to consider factors like hardness, lubrication properties, and thermal expansion.

Here are some tips for proper pairing:

Pairing Tungsten Carbide with Soft Metals

Pairing tungsten carbide with softer metals, such as bronze or copper, can reduce the risk of galling.

These metals offer better lubricating properties and absorb some of the stress that would otherwise be placed on the tungsten carbide.

Using High-Quality Lubricants

A high-quality lubricant can act as a barrier between the surfaces, reducing friction and preventing galling. Proper lubrication is especially important in high-load or high-speed applications.

Consider Material Hardness Matching

When pairing tungsten carbide with other hard materials, such as steel, ensure that the hardness is matched to avoid excessive wear on either surface.

Nickel-bonded tungsten carbide may be more suitable for pairing with steel in certain applications due to its improved toughness.

2). Importance of Surface Treatment and Coatings

Another effective way to reduce friction and prevent galling is through the use of surface treatments or coatings.

Coatings like TiN (Titanium Nitride) or DLC (Diamond-Like Carbon) can improve the lubricity of tungsten carbide surfaces and significantly reduce friction.

Surface polishing can also reduce roughness and improve the bushing’s ability to slide smoothly against its mating components.

3). Monitoring and Maintenance

Regular maintenance and inspections are key to ensuring that friction and galling remain under control. This includes:

Monitoring Wear Patterns: Inspect the bushings and other parts regularly for signs of wear, surface degradation, or misalignment.

Lubrication Checks: Ensure that proper lubrication is maintained, especially in high-speed or high-load applications.

Best Practices for Reducing Friction and Galling

1). Regular Inspections and Monitoring

Frequent checks of the tungsten carbide components can help detect early signs of friction or galling.

It’s essential to inspect the wear patterns and assess the alignment of bushings, seals, and other moving parts.

2). Choosing the Right Lubrication

Proper lubrication plays a key role in reducing friction and preventing galling. Ensure that the correct lubricants are used based on the specific application and materials involved.

For high-speed applications, grease or oil with extreme pressure additives can be beneficial.

3). Temperature Control and Thermal Management

As friction generates heat, it’s important to control the temperature in the system.

Implementing cooling systems or using materials with higher thermal conductivity can help dissipate the heat generated by friction and reduce wear on the tungsten carbide components.

Conclusión

Reducing friction and galling in tungsten carbide bushings is crucial for maintaining optimal performance and extending the service life of machinery.

By selecting the right materials for pairing, using proper lubrication, and implementing effective surface treatments, industries can significantly reduce wear and improve the efficiency of their operations.

Regular inspections and maintenance are also key to ensuring that friction and galling do not cause damage over time.

By understanding the importance of proper tungsten carbide pairing, you can avoid costly repairs and downtime, while ensuring the long-term success of your machinery.

Si desea conocer más detalles sobre alguna empresa, no dude en contactarnos. Contáctanos.