Refinery charge and bottoms pumps work in tough conditions. They handle high pressure, high temperature, and aggressive fluids.

Elegir lo correcto anillos de sellado de carburo is critical for safe operation, lower maintenance costs, and longer pump life.

This guide uses simple words and clear steps to help refinery decision-makers choose the best seal rings.

Why Carbide Seal Rings Matter

Anillos de sellado de carburo are made from very hard materials like tungsten carbide or silicon carbide.

These materials resist wear, heat, and chemical attack better than steel or ceramic. In refinery charge and bottoms pumps, good seals help to:

Prevent dangerous leaks of hydrocarbons

Reduce pump downtime and repair costs

Improve pump efficiency and reliability

Protect workers and the environment

Types of Carbide Materials

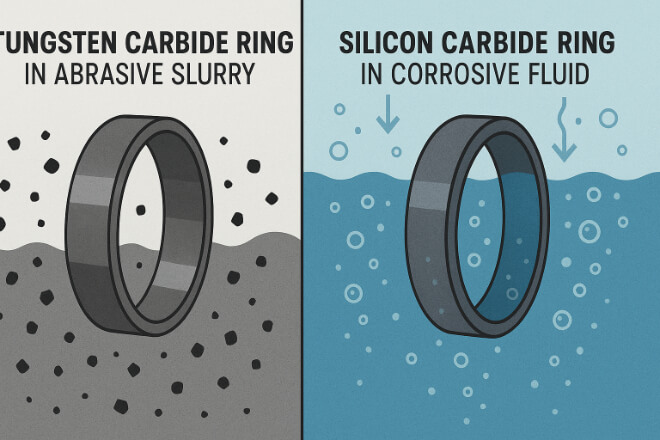

1). Tungsten Carbide (WC)

Extremely hard and strong

Works well with abrasive fluids and heavy loads

Usually contains cobalt or nickel binders for tenacidad o Resistencia a la corrosión

2). Silicon Carbide (SiC)

Excellent chemical resistance

Lighter weight, reducing shaft load

More brittle, so less suited to shock loads

3). Binder Options

Cobalt Binder: Tough and handles shock well but can corrode in sour service

Nickel Binder: Better corrosion resistance for acidic or aggressive fluids

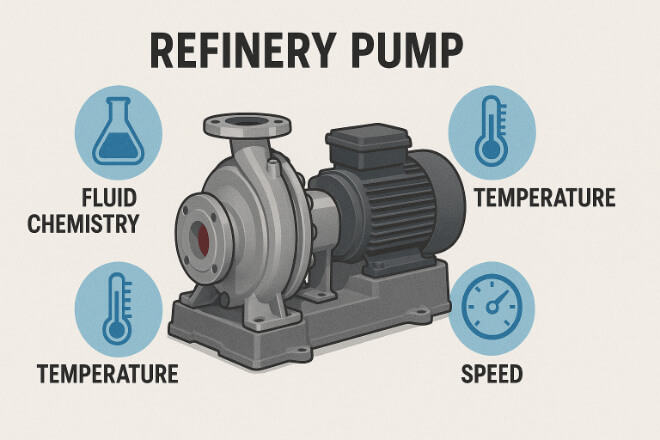

Key Factors for Selection

1). Fluid Chemistry

Heavy bottoms or light hydrocarbons?

Sour or acidic fluids?

Abrasive slurries or solids?

Choose silicon carbide for high corrosion risk. Use tungsten carbide for abrasive fluids.

2). Temperature and Pressure

Refinery pumps may face over 400 °F (200 °C) and very high pressures. Tungsten carbide works well under extreme stress.

Silicon carbide can handle heat but must be protected from thermal shock.

3). Pump Speed and Load

Higher shaft speeds create more frictional heat. Pick ring grades with strong wear resistance. Tungsten carbide’s strength is ideal for heavy loads.

4). Mechanical Seal Design

Decide between balanced or unbalanced seals

Check face pairings: carbide vs. carbon or carbide vs. carbide

Include flush or cooling systems to avoid dry running

5). Standards and Compliance

Follow API 682 or other refinery standards. Choose suppliers with ISO 9001 or similar certifications.

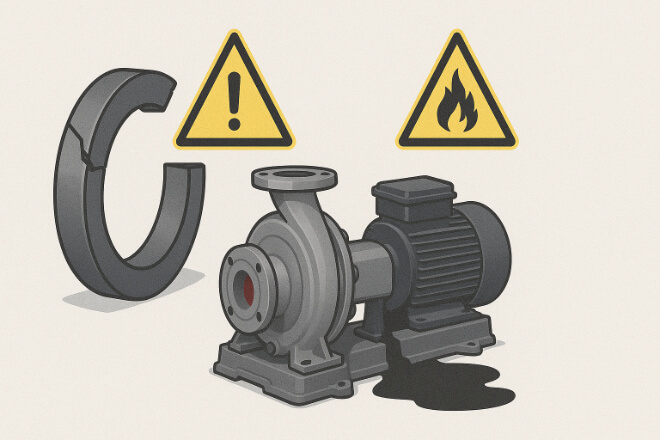

Common Errors to Avoid

Selecting cobalt binder in corrosive sour service

Ignoring thermal shock limits for silicon carbide

Skipping flush systems, leading to dry running and wear

Choosing suppliers without refinery experience or fast support

Cost vs. Long-Term Value

Carbide seal rings are more expensive upfront but cheaper over time. They:

Reduce unplanned shutdowns

Extend pump and seal life

Lower environmental and safety risks

Considering total cost of ownership can help justify the higher initial price.

Supplier Selection Tips

Pick suppliers with proven refinery experience

Ask for engineering support and local inventory

Verify that material grades are traceable and genuine

Check case studies or references

| Tipo de carpeta | Ventaja principal | Best Application |

|---|---|---|

| Cobalt | High toughness and shock resistance | Abrasive slurries and high mechanical stress |

| Nickel | Excellent corrosion resistance | Sour service and aggressive chemicals |

Maintenance Best Practices

Inspect seal faces during planned shutdowns

Use clean flush water or compatible process fluid

Replace rings before cracks or scoring appear

Train staff on proper installation torque and alignment

Environmental and Safety Benefits

Leaks in refinery pumps can cause fire, emissions, or injury.

Correct carbide seal ring selection prevents spills and supports environmental compliance.

Investing in high-quality rings protects both people and equipment.

Conclusión

Selecting the right carbide seal rings for refinery charge and bottoms pumps is about more than price.

Decision-makers should look at fluid chemistry, temperature, binder type, standards, and supplier support. Using high-quality carbide rings ensures pump reliability, safety, and lower lifetime costs.

Si desea conocer más detalles sobre alguna empresa, no dude en contactarnos. Contáctanos.