In modern manufacturing, trust and traceability are everything. When it comes to bujes de carburo de tungsteno, one missing document can mean serious trouble — machine failure, rejected batches, or even safety violations.

That document is the material certification.

Material certification proves that the bushings you receive were made using verified raw materials that meet required chemical and mechanical standards.

It gives assurance that every component — from tungsten powder to binder ratio — is exactly as specified.

For companies in petróleo y gas, chemical, power, and machinery industries, certified carbide bushings are not optional — they are a requirement.

This article explains what material certification means, why it matters, and how to evaluate it when selecting your tungsten carbide bushing supplier.

What Is a Material Certification?

A material certification (sometimes called a mill certificate or inspection certificate) is a formal document issued by the manufacturer that confirms the materials used in production meet the required specifications.

Para bujes de carburo de tungsteno, it includes data such as:

Chemical composition

Binder content (Cobalt or Nickel)

Dureza (HRA)

Grain size and microstructure

Production batch and inspection date

This certificate acts as proof of quality and traceability, showing that each batch of bushings meets international or client-specific standards.

Common Certification Standards for Carbide Bushings

Different industries and clients require different types of material certificates. Below is a table showing the most common standards and what each represents.

| Certification Type | Standard | Descripción | Uso típico |

|---|---|---|---|

| EN 10204 2.1 | European Standard | Statement of compliance without test results | Basic supply chains |

| EN 10204 3.1 | European Standard | Certified test results verified by manufacturer’s quality department | Oil & Gas, Power, Chemical |

| EN 10204 3.2 | Third-Party Verified | Independent inspector confirms compliance | Critical safety or export projects |

| ISO 9001 | Quality Management | Factory-level quality assurance system | All manufacturing industries |

If your equipment works in harsh or regulated environments, EN 10204 3.1 or higher is the certification level you should expect.

Why Material Certification Matters

For decision-makers, certification is not paperwork — it’s risk management.

Here’s why it’s so critical in tungsten carbide bushing sourcing:

1). Ensures Material Authenticity

Certificates confirm that the tungsten carbide, cobalt, or nickel used are of verified purity and correct ratio. Low-quality substitutes lead to early wear or cracking.

2). Verifies Mechanical Properties

Certified dureza, densidad, y tenacidad data prove the part will perform under the intended load, temperature, and chemical exposure.

3). Enables Full Traceability

Each batch is marked with a unique number, allowing investigation if any failure occurs later in service.

4). Meets Regulatory and Client Requirements

Many industries — especially petróleo y gas y aeroespacial — require proof of certification for every component before acceptance.

5). Protects Brand Reputation

Using uncertified or unverified parts risks failures that could harm your company’s credibility and cause financial loss.

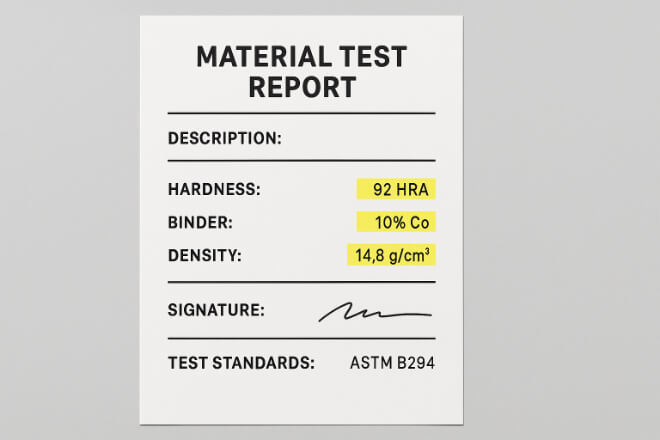

What Should Be Included in a Good Material Certificate

Not all certificates are equally detailed.

A strong and trustworthy material certification for tungsten carbide bushings should include:

Manufacturer’s name and address

Batch number and date

Product grade and code

Chemical composition (WC + binder %)

Dureza value (HRA or HV)

Densidad (g/cm³)

Grain size (µm)

Inspector signature and approval stamp

Reference to test standard (ISO, ASTM, EN, etc.)

Below is an example summary of what a typical data section might contain.

| Propiedad | Especificación | Measured Value | Standard |

|---|---|---|---|

| Dureza (HRA) | 89.5–92.0 | 91.6 | ASTM B294 |

| Densidad (g/cm³) | 14.4–14.9 | 14.7 | ISO 3369 |

| Binder Content (Co%) | 6 ± 0.3 | 5.9 | ISO 4499 |

The presence of measurable data and standards ensures that you’re not just trusting — you’re verifying.

How Material Certification Helps in Quality Assurance

Certified materials help your quality control team maintain consistency and compliance.

Incoming inspection: Verifies that delivered bushings match purchase specifications.

Internal traceability: Links each bushing batch to a documented production record.

Failure analysis: Helps identify whether wear or fracture was due to material deviation.

Audit readiness: Makes ISO or client audits smoother with clear documentation.

In many industries, auditors specifically check for traceable material certificates as part of supplier evaluation.

Supplier Responsibility and Buyer Verification

Both supplier and buyer share responsibility in the certification process:

Suppliers must issue authentic, traceable, and test-backed certificates for each batch.

Buyers must verify the documents before accepting shipments.

When reviewing certificates, buyers should:

Cross-check batch numbers on the document and product.

Confirm test standards and reference codes.

Look for authorized quality engineer signatures.

Reject any certificates that appear generic or missing data.

A professional supplier will always welcome verification and explain their test procedures openly.

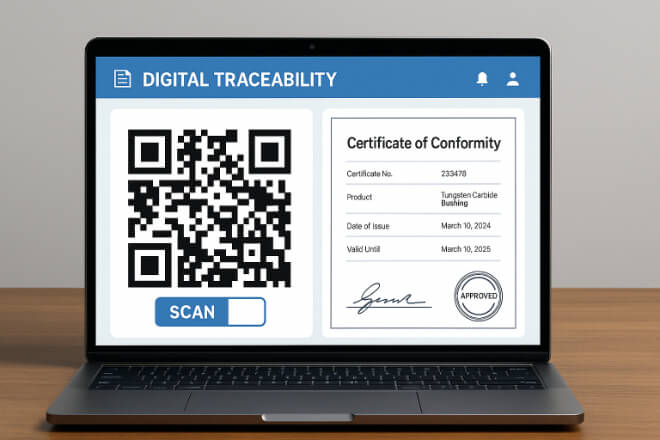

Digital Material Certification Systems

Today, many advanced manufacturers have moved from paper certificates to digital traceability systems.

These allow clients to:

Download PDF certificates for each batch directly from a secure server

Access full test data for audit purposes

Link certificates to production QR codes or serial numbers

Such systems reduce human error and strengthen supply chain transparency — an important factor for global OEMs and regulated industries.

Conclusión

Material certification is far more than a formality — it’s the foundation of trust, compliance, and reliability in tungsten carbide bushing sourcing.

It guarantees that every bushing installed in your pump, compressor, or turbine is made from verified materials that meet required performance standards.

Working with suppliers who provide detailed, transparent, and test-backed certificates helps your company minimize risk, maintain quality, and strengthen long-term credibility in global markets.

Si desea conocer más detalles sobre alguna empresa, no dude en contactarnos. Contáctanos.