Puntas de carburo de tungsteno are crucial in many industries, from mining to manufacturing, due to their superior dureza, resistencia al desgaste, and durability. These properties make them the ideal choice for cutting, drilling, and other high-performance tools.

But how are these incredible materials made? In this blog, we will explore the step-by-step manufacturing process of tungsten carbide tips, from raw materials to the finished product.

Understanding this process is essential for engineers and decision-makers who rely on tungsten carbide tips for their operations.

Raw Material Selection for Tungsten Carbide Tips

The manufacturing process begins with the selection of raw materials. Tungsten carbide is a composite material made primarily of tungsten and carbon, with a binder material like cobalt or nickel.

The right balance of these materials is crucial for achieving the desired dureza, tenacidad, and other mechanical properties in the final product.

1). Tungsten Powder and Binder Materials

Tungsten Powder: The primary component of tungsten carbide, known for its extreme hardness.

Binder Materials (Cobalt or Nickel): These materials provide strength and toughness, ensuring the carbide is not too brittle.

Carbon: Carbon is essential to forming tungsten carbide through the reaction with tungsten powder.

Mixing and Milling Process

Once the raw materials are selected, the next step is to mix the tungsten powder with the binder material.

The mixing process ensures that the carbide powder is evenly distributed, creating a consistent material with the desired properties.

1). The Milling Process

The tungsten powder and binder are placed in a ball mill, where they are ground into a fine mixture.

This mixture is then dried and compacted into a uniform powder. The milling process helps achieve the fine particle size needed to form strong, uniform tungsten carbide.

Compaction and Shaping

Once the powder mixture is prepared, the next step is shaping the material into the desired form.

This is done through a process called compaction, where the powder is compressed into a mold under high pressure. The result is a “green” tungsten carbide part—still not fully sintered, but with the basic shape.

1). Cold Pressing

Cold pressing involves pressing the powder into a mold at room temperature. This step ensures that the tungsten carbide has the necessary shape to begin the sintering process.

This step is critical for achieving the correct dimensions and density of the finished tips.

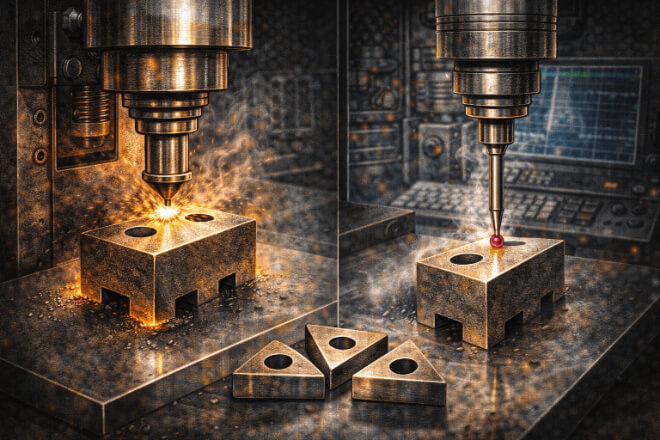

Sintering Process: Hardening Tungsten Carbide

The next stage is sintering, where the compacted tungsten carbide part is heated to a very high temperature (over 1400°C) in a furnace.

During this step, the binder material melts and bonds the tungsten particles together, forming a solid, dense material.

1). High-Temperature Furnace

The part is heated in a controlled atmosphere furnace. The temperature and time are carefully controlled to ensure the final product achieves the desired dureza and density.

Sintering is one of the most critical stages in producing tungsten carbide tips because it determines the material’s strength and resistencia al desgaste.

Cooling and Post-Sintering Operations

After the sintering process, the tungsten carbide tips must be cooled slowly to prevent any cracking or distortion. The cooling process ensures that the tips retain their shape and dureza.

1). Finishing Operations

After cooling, the tungsten carbide tips undergo finishing operations such as grinding, lapping, and polishing to achieve the desired dimensions and surface finish.

These finishing touches ensure that the tips meet the required tolerances for their specific application.

Quality Control and Testing

Once the tungsten carbide tips have been shaped and finished, they undergo rigorous testing and quality control checks.

This ensures that they meet industry standards for hardness, density, and other essential properties.

1). Dureza Testing

One of the key tests performed on tungsten carbide tips is the hardness test. The tips must pass strict hardness criteria to ensure they can withstand the intense wear and tear they will face during operation.

2). Visual and Dimensional Inspection

Tips are also inspected visually to check for defects such as cracks or surface imperfections. Dimensional inspections ensure that the tips meet the required specifications, including shape and size.

Final Product and Packaging

After passing the quality control tests, the tungsten carbide tips are ready for shipment. They are carefully packaged to ensure they are protected during transit and storage.

Packaging materials such as anti-static bags or protective coatings are used to prevent damage during handling.

1). Packaging for Protection

Proper packaging helps prevent the tips from being damaged by environmental factors like moisture or physical impact.

This ensures that the tips arrive at their destination in perfect condition, ready for use in cutting, drilling, or other applications.

Conclusión

The manufacturing process of tungsten carbide tips involves several critical stages, from raw material selection and mixing to sintering, finishing, and quality control.

Each step is designed to ensure that the final product is of the highest quality, capable of withstanding extreme conditions and providing long-lasting performance.

By understanding this process, companies can better appreciate the value of tungsten carbide tips and make informed decisions about their use in various industrial applications.

Si desea conocer más detalles sobre alguna empresa, no dude en contactarnos. Contáctanos.