Tungsten carbide is one of the most important materials in modern manufacturing.

Known for its exceptional dureza, tenacidad, y resistencia al desgaste, it is used in Herramientas de corte, mining equipment, wear parts, and many industrial applications.

But behind these impressive properties lies the science of metallurgy — the study of how metals and alloys are designed, processed, and optimized.

Understanding the metallurgy of tungsten carbide helps decision-makers select the right grade for specific applications, improve tool life, and reduce costs.

This article explains the composition, structure, manufacturing process, and performance factors that make tungsten carbide so valuable in industry.

¿Qué es el carburo de tungsteno?

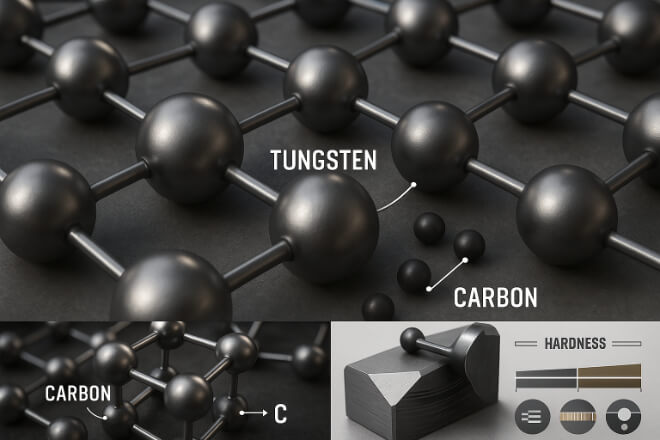

Tungsten carbide is a compound made of tungsten (W) and carbon (C). The formula is WC, meaning each molecule contains one tungsten atom and one carbon atom.

Tungsten provides dureza and density.

Carbon forms strong chemical bonds that make the material wear-resistant.

In most industrial applications, tungsten carbide is cemented with a metal binder such as cobalt (Co) or nickel (Ni) to improve tenacidad.

This combination results in a material that is harder than steel, but much tougher than pure ceramics.

Key Properties of Tungsten Carbide

Tungsten carbide is unique because it combines properties that are usually opposite in other materials.

| Propiedad | Valor típico | Importance in Industry |

|---|---|---|

| Hardness (HV) | 1400–2400 | Resists wear and abrasion |

| Densidad | 14–15 g/cm³ | Provides stability in tools |

| Melting Point | ~2,870°C (5,198°F) | High-temperature resistance |

| Resistencia a la compresión | 4000 MPa+ | Handles extreme loads |

| Tenacidad | Depends on binder content | Resists cracking and chipping |

The Role of Metallurgy in Tungsten Carbide

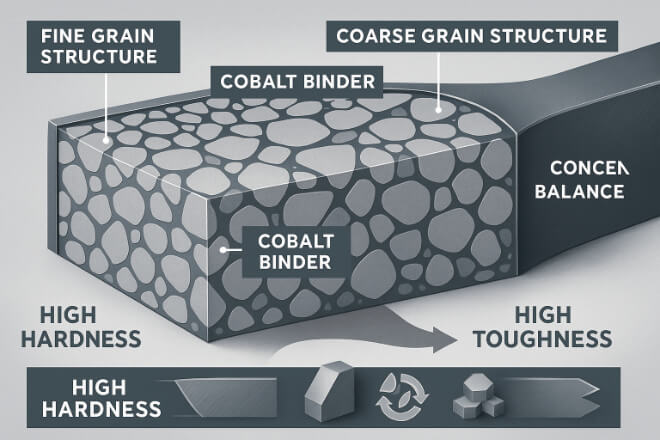

Metallurgy is not just about mixing tungsten and carbon. It involves controlling grain size, binder content, and distribution to achieve the desired balance between dureza and toughness.

Grain Size: Fine grains increase hardness but reduce tenacidad; coarse grains improve toughness but lower hardness.

Binder Content: More cobalt increases toughness but can lower hardness.

Additives: Small amounts of other carbides (like titanium carbide, TaC) can improve heat resistance or reduce grain growth.

How Tungsten Carbide Is Made — The Powder Metallurgy Process

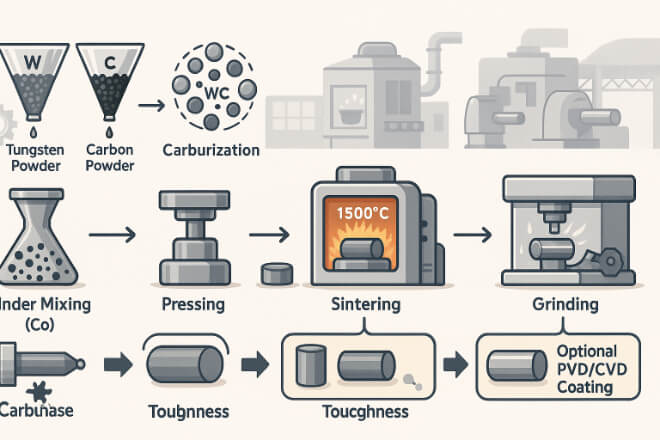

Tungsten carbide is manufactured using powder metallurgy, which allows precise control of its properties.

Step-by-step process:

Powder Preparation – Tungsten and carbon powders are measured and mixed.

Carburization – The mixture is heated to form WC particles.

Binder Addition – Cobalt or nickel powder is added to the mixture.

Mixing and Milling – Ensures even distribution of carbide grains and binder.

Pressing – The mixture is pressed into the desired shape.

Sintering – The pressed piece is heated to near melting point to bond particles together.

Finishing – Grinding, coating, or polishing to meet dimensional requirements.

Controlling Hardness and Toughness

The metallurgy of tungsten carbide focuses on balancing hardness and toughness to match application needs.

Alto Dureza Grades – Ideal for cutting hard materials (fine-grain, low binder).

Alto Tenacidad Grades – Ideal for impact or shock load (coarse-grain, high binder).

Balanced Grades – Used in general-purpose wear parts.

Grade Selection Guide

| Tipo de grado | Hardness Level | Toughness Level | Mejores aplicaciones |

|---|---|---|---|

| Grano fino, bajo aglutinante | Alto | Bajo | Precision cutting tools |

| Grano medio, aglutinante medio | Medio | Medio | General wear parts |

| Grano grueso, alto aglutinante | Más bajo | Alto | Mining tools, impact-resistant parts |

Industrial Applications of Tungsten Carbide

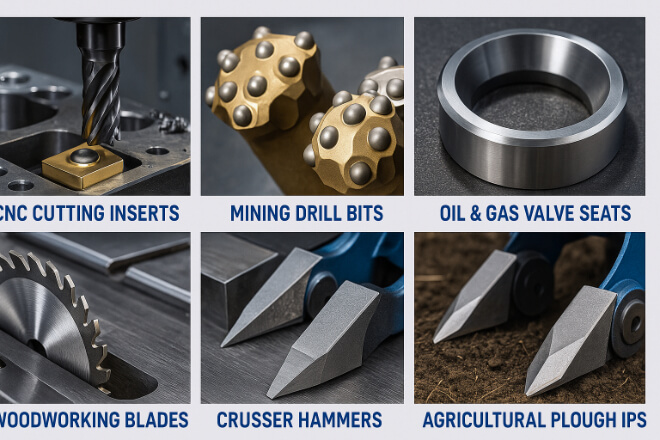

The versatility of tungsten carbide comes from its tunable metallurgy.

Metal Cutting Tools – Milling cutters, drills, inserts.

Minería and Drilling – Buttons, tips, and wear plates.

Petróleo y gas – Valve seats, nozzles, downhole tools.

Woodworking – Planer blades, saw tips.

Agriculture – Plough blades, soil-engaging parts.

The Future of Tungsten Carbide Metallurgy

Research is pushing boundaries with:

Nano-grain tungsten carbide for higher dureza without losing toughness.

Advanced coatings (TiAlN, DLC) to improve heat and resistencia al desgaste.

Recycling processes to recover tungsten and cobalt from worn tools.

These innovations are making carbide parts last longer, perform better, and be more sustainable.

Conclusión

The metallurgy of tungsten carbide is the key to its success in industrial applications.

By controlling grain size, binder content, and additives, manufacturers create materials with the right balance of hardness and toughness for each job.

For decision-makers, understanding these factors means making better choices that improve performance, extend tool life, and reduce downtime.

Si desea conocer más detalles sobre alguna empresa, no dude en contactarnos. Contáctanos.